Description

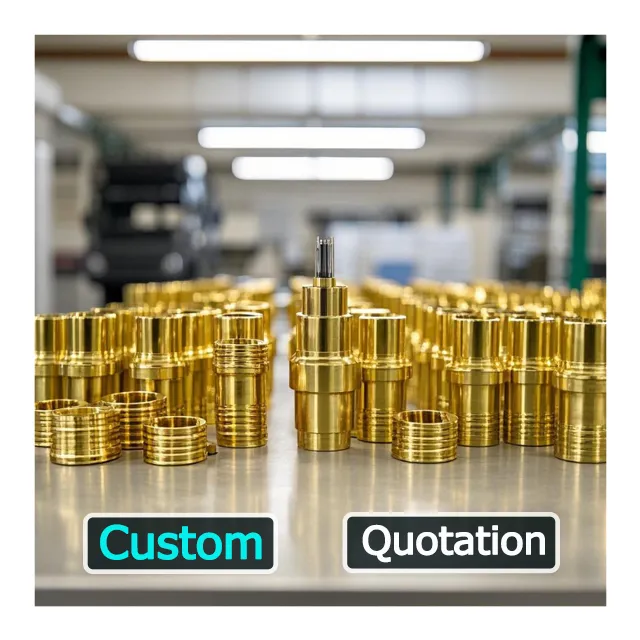

We use environmentally – friendly brass grades such as C36000 and HPb62, with a density of 8.5g/cm³ and a tensile strength of ≥ 335MPa. These materials combine high strength with excellent cutting performance, enabling high – speed processing and producing uniform and fine chips.

Stainless steels (303/304/316L), aluminum alloys (6061/7075), titanium alloys, and engineering plastics (PEEK/POM) are available, meeting the needs of various scenarios.

- Dimensional Control: The basic tolerance is ±0.005 – 0.01mm, and it can be customized to ±0.001mm, suitable for micron – level precision components.

- Surface Treatment: The roughness ranges from Ra0.2 – 3.2. Processes such as mirror polishing, anodizing (black/colored), electroplating, and sandblasting are supported, enhancing corrosion resistance and aesthetics.

- Machine Performance: Equipped with a cradle – type worktable, it supports the one – time clamping and forming of 3D curved surfaces, complex cavities, and special – shaped structures, reducing repeat positioning errors (error ≤ 0.02mm).

- Tool System: Carbide / diamond – coated tools are used, suitable for high – speed cutting (rotation speed ≥ 20,000 RPM). Turning, drilling, and wire electrical discharge machining processes are integrated to shorten the processing cycle.

- Programming Compatibility: It supports formats such as STEP/IGES/CAD/DWG, provides design optimization suggestions, and enables interference – free machining of complex geometric bodies.

- Adaptive Control: Equipped with the Heidenhain numerical control system, it can adjust cutting parameters in real – time, optimize the tool path, and extend the tool life.

- Equipment: Coordinate measuring machines (CMM), tool microscopes, and roughness testers are used for full – inspection of key dimensions and surface quality.

- Standards: It has passed ISO9001:2015 and AS9100 aerospace certifications, ensuring batch consistency.

- Deburring Technology: A combination of chemical cleaning and laser processes is used to remove sharp edges and ensure assembly accuracy.

- Anti – deformation Design: Clamping schemes and cutting parameters are optimized to reduce the risk of deformation during the processing of thin – walled parts.

- Precision Instruments: Sensor housings, optical brackets, and components of medical equipment (such as hardware parts of oximeters).

- Automotive Industry: Fuel injection components, transmission gears, and 3D – printed prototype verification parts.

- Aerospace: Engine blade fixtures, navigation system housings, and lightweight titanium – alloy structural parts.

- Minimum Order Quantity: Supports sample 试制 from 1 piece to batch orders of 1000 pieces.

- Delivery Cycle: Samples take 3 – 7 days, and batch orders take 7 – 30 days (including surface treatment and quality inspection).

- Packaging Solution: Rust – proof paper + EPE foam + customized cartons/pallets to meet the protection requirements of international transportation.

- After – sales Support: Provide process documents, design optimization consulting, and emergency order expediting services.

Typical processing cases include heart – shaped curved surface mirror – polished parts (roughness Ra0.2), miniature titanium – alloy aerospace connectors (tolerance ±0.003mm), etc.

If you need to obtain a complete technical white paper or customized solutions, please provide specific drawings and performance requirements.

We use environmentally – friendly brass grades such as C36000 and HPb62, with a density of 8.5g/cm³ and a tensile strength of ≥ 335MPa. These materials combine high strength with excellent cutting performance, enabling high – speed processing and producing uniform and fine chips.

Stainless steels (303/304/316L), aluminum alloys (6061/7075), titanium alloys, and engineering plastics (PEEK/POM) are available, meeting the needs of various scenarios.

- Dimensional Control: The basic tolerance is ±0.005 – 0.01mm, and it can be customized to ±0.001mm, suitable for micron – level precision components.

- Surface Treatment: The roughness ranges from Ra0.2 – 3.2. Processes such as mirror polishing, anodizing (black/colored), electroplating, and sandblasting are supported, enhancing corrosion resistance and aesthetics.

- Machine Performance: Equipped with a cradle – type worktable, it supports the one – time clamping and forming of 3D curved surfaces, complex cavities, and special – shaped structures, reducing repeat positioning errors (error ≤ 0.02mm).

- Tool System: Carbide / diamond – coated tools are used, suitable for high – speed cutting (rotation speed ≥ 20,000 RPM). Turning, drilling, and wire electrical discharge machining processes are integrated to shorten the processing cycle.

- Programming Compatibility: It supports formats such as STEP/IGES/CAD/DWG, provides design optimization suggestions, and enables interference – free machining of complex geometric bodies.

- Adaptive Control: Equipped with the Heidenhain numerical control system, it can adjust cutting parameters in real – time, optimize the tool path, and extend the tool life.

- Equipment: Coordinate measuring machines (CMM), tool microscopes, and roughness testers are used for full – inspection of key dimensions and surface quality.

- Standards: It has passed ISO9001:2015 and AS9100 aerospace certifications, ensuring batch consistency.

- Deburring Technology: A combination of chemical cleaning and laser processes is used to remove sharp edges and ensure assembly accuracy.

- Anti – deformation Design: Clamping schemes and cutting parameters are optimized to reduce the risk of deformation during the processing of thin – walled parts.

- Precision Instruments: Sensor housings, optical brackets, and components of medical equipment (such as hardware parts of oximeters).

- Automotive Industry: Fuel injection components, transmission gears, and 3D – printed prototype verification parts.

- Aerospace: Engine blade fixtures, navigation system housings, and lightweight titanium – alloy structural parts.

- Minimum Order Quantity: Supports sample 试制 from 1 piece to batch orders of 1000 pieces.

- Delivery Cycle: Samples take 3 – 7 days, and batch orders take 7 – 30 days (including surface treatment and quality inspection).

- Packaging Solution: Rust – proof paper + EPE foam + customized cartons/pallets to meet the protection requirements of international transportation.

- After – sales Support: Provide process documents, design optimization consulting, and emergency order expediting services.

Typical processing cases include heart – shaped curved surface mirror – polished parts (roughness Ra0.2), miniature titanium – alloy aerospace connectors (tolerance ±0.003mm), etc.

If you need to obtain a complete technical white paper or customized solutions, please provide specific drawings and performance requirements.