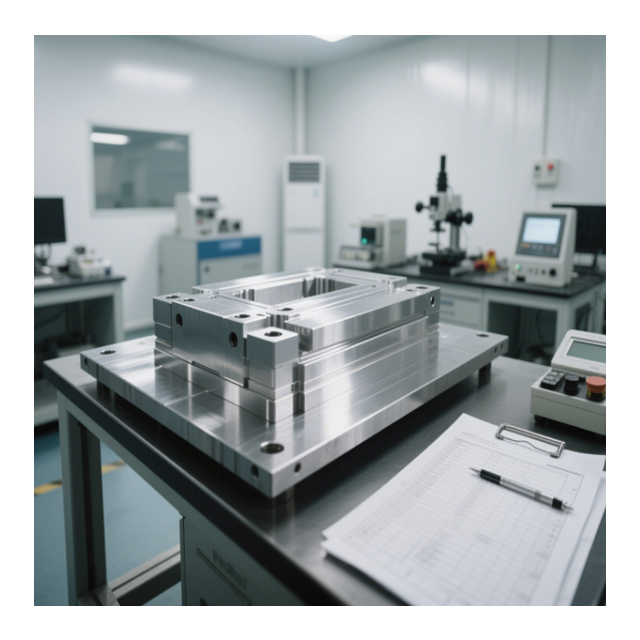

| Mold Material |

Steel (P20/718/H13/45#/S136, etc.) / Stainless steel/aluminum/copper |

| Product Type |

Plastic injection molds (single cavity/multi-cavity support) |

| Processed Materials |

Plastics (PA/PP/PU/ABS/PC/POM/PEEK, etc.), silicone, metals (customizable) |

| Size |

Customized to customer requirements |

| Certifications |

ISO 9001:2008, RoHS |

| MOQ |

1 piece (no minimum quantity restriction) |

| Lead Time |

31 days for 1 piece; negotiable for bulk orders |

| Design Support |

Accepts 3D drawings (STP/STEP/IGS, etc.), supports sample scanning & modeling |

| Surface Treatments |

Nickel plating, anodizing, chrome plating, polishing, sandblasting, etc. |

| Packaging |

Wooden cases/cartons/pallets (standard size: 55×55×55 cm, weight: 52.35 kg) |

| Shipping Methods |

Sea freight/air freight/international logistics (DHL/UPS/FedEx, etc.) |

| Factory Qualifications |

25+ years of experience, 1,000+㎡ workshop, 100+ CNC machines (including 5-axis CNC), 1,000,000 pcs/month capacity |

| Quality Control |

100% full inspection (CMM coordinate measuring), quality reports provided |

| Main Applications |

Automotive parts, communication equipment, medical devices, daily necessities, digital products |