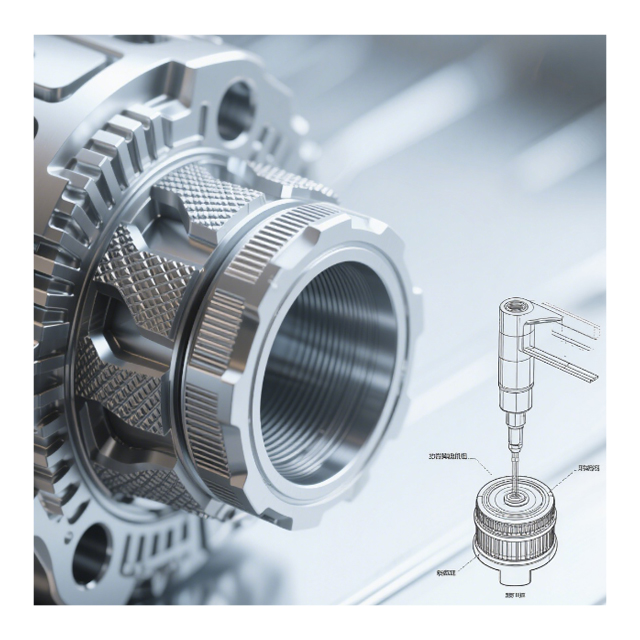

Hybrid CNC & 3D Metal Fabrication Services

Description

Bridging subtractive and additive manufacturing, our integrated service delivers precision metal components with complex geometries unachievable through conventional methods. Combining German DMG MORI 5-axis CNC centers with EOS M400-4 metal 3D printers, we enable functional prototypes to end-use production parts with exceptional mechanical properties and reduced lead times.

Hybrid Manufacturing Advantages:

• Topology Optimization: 3D print lightweight structures with internal channels + CNC finish critical interfaces

• Material Efficiency: Additive near-net-shape reduces CNC material waste by 40-70%

• Consolidated Assemblies: Convert multi-part assemblies into single 3D printed units with post-CNC machining

Advanced Material Processing:

-

Aerospace Alloys: Ti6Al4V ELI (Grade 23) with HIP treatment for 99.9% density

-

Medical Compliance: 316L stainless with biocompatible surface options

-

Thermal Management: Copper C18150 with conformal cooling channels

Technical Workflow:

-

Design Phase: DFAM (Design for Additive Manufacturing) analysis including support structure optimization

-

Build Process: Inert argon environment printing with real-time melt pool monitoring

-

Post-Processing: Stress relief heat treatment • CNC precision machining • Micro-bead blasting

-

Validation: CT scanning for internal defect detection • CMM for dimensional verification

Industry-Specific Solutions:

✓ Automotive: Fuel injectors with conformal cooling (20% efficiency improvement)

✓ Aerospace: Satellite brackets with 60% weight reduction

✓ Medical: Patient-specific implants with porous bone-ingrowth structures

✓ Robotics: Custom actuator housings with embedded sensors

Quality Assurance Systems:

-

Powder characterization: Sieve analysis and flow rate testing (ASTM B213/B964)

-

Mechanical testing: Tensile strength and fatigue reports (ISO 6892-1/ASTM E466)

-

Traceability: Full digital production records with unique part IDs

Unique Capabilities:

• Internal thread machining in 3D printed cavities (M1.6 and above)

• Multi-material integration (metal-polymer interfaces)

• Surface densification for improved corrosion resistance

Value-Added Services:

-

Free design optimization for hybrid manufacturing

-

Material test coupons with production parts

-

Expedited 24-hour quoting for urgent projects

Special Offer: First-order discount of 5% on combined CNC + 3D printing orders over 50 units.

→ Submit your project to receive:

① Manufacturability assessment report

② Material selection guide

③ Post-processing options comparison

Describe your application requirements below – our hybrid manufacturing engineers will provide technical solutions within 6 business hours!