Industrial-Grade Modular Plastic Storage Cabinet

| Parameter | Specification |

|---|---|

| Material Composition | Virgin HDPE (High-Density Polyethylene) |

| Wall Thickness | 1.5mm (Body) • 2.0mm (Shelves) |

| Load Capacity | 100kg/shelf • 300kg/total |

| Dimensions (L×W×H) | 600×400×800mm (Standard) |

| Stackability | Up to 3 units high |

| Color Options | Blue/Black/Gray/Red (RAL Customization) |

| Special Features | Anti-static • UV-resistant • Chemical-proof |

| Mobility | 4×360° Swivel Casters (2 with brakes) |

| Certifications | SGS • ISO 9001 • REACH |

| Temperature Resistance | -30°C to +80°C |

| MOQ | 50 Units (Customization Available) |

Description

Engineered for industrial and commercial environments, our heavy-duty HDPE storage cabinets provide superior chemical resistance and structural integrity compared to traditional metal alternatives. Manufactured using rotational molding technology with virgin-grade polyethylene, these units eliminate corrosion risks while maintaining stability in harsh conditions from automotive workshops to pharmaceutical warehouses.

Advanced Material Performance:

• Chemical Immunity: Withstands acids, alkalis, and solvents (including IPA and acetone) without degradation

• Impact Resistance: 8J/cm² toughness rating withstands tool drops and forklift impacts

• Hygienic Design: Seamless construction prevents bacterial growth (FDA-compliant for food processing)

Engineering Features:

-

Reinforced Structure: Ribbed sidewalls and double-thick shelves prevent deformation under load

-

Secure Access: Key-lockable doors with tamper-proof hinges and integrated latch systems

-

Modular Flexibility: Interlocking corner design enables secure vertical stacking (no tools required)

-

Mobility System: Industrial-grade casters with 80kg load capacity each (10,000+ roll cycles)

Industry-Specific Advantages:

✓ Electronics Manufacturing: ESD-safe version available (surface resistance 10⁶-10⁹ Ω)

✓ Laboratories: Chemical-resistant models for OSHA-compliant hazardous material storage

✓ Outdoor Use: UV-stabilized formulation withstands 5+ years direct sunlight exposure

✓ Food Processing: FDA-compliant blue pigment for HACCP compliance

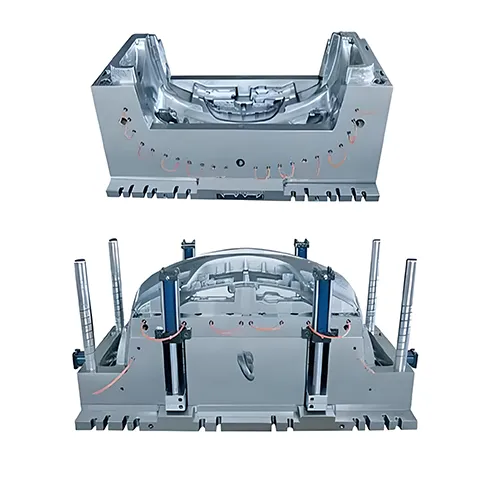

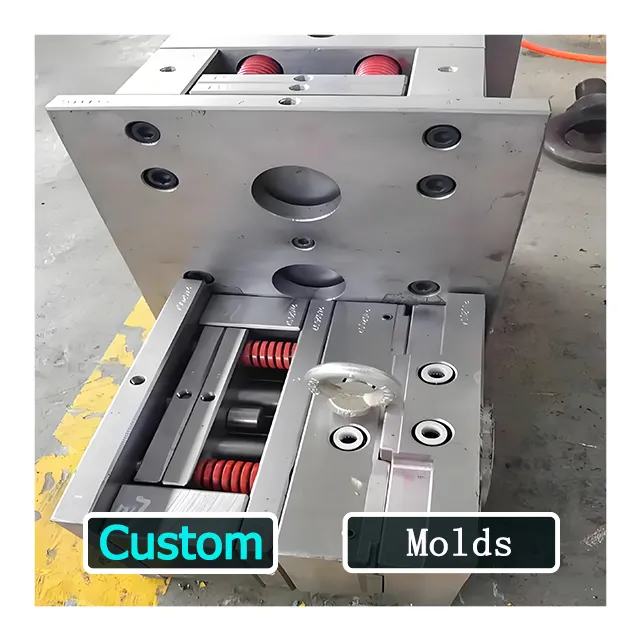

Customization Options:

-

Size Variations: From compact 400mm depth to 1200mm industrial sizes

-

Accessory Integration: Optional parts bins, drawer inserts, and label holders

-

Safety Features: Flame-retardant additives (UL 94 HB rating) available

-

Branding: Laser-etched logos or custom color matching

Quality Validation:

-

Material testing: Melt flow index (MFI) and density verification

-

Load testing: 150% overloading for 72 hours

-

Environmental testing: 500-hour salt spray and UV exposure

-

Cycle testing: 10,000+ door open/close repetitions

Operational Benefits:

• 40% lighter than steel equivalents reducing shipping costs

• Non-conductive properties enhance electrical safety

• Maintenance-free surfaces clean with industrial detergents

• Noise reduction compared to metal storage solutions

Value-Added Services:

-

Free 3D cabinet configuration design

-

On-site storage analysis consultations

-

Custom foam insert fabrication

→ Contact us today to receive:

① Custom layout proposals

② Material safety data sheets

③ Site-specific configuration recommendations

Message us your storage requirements and facility photos – our space optimization specialists will provide a tailored solution within 24 hours!