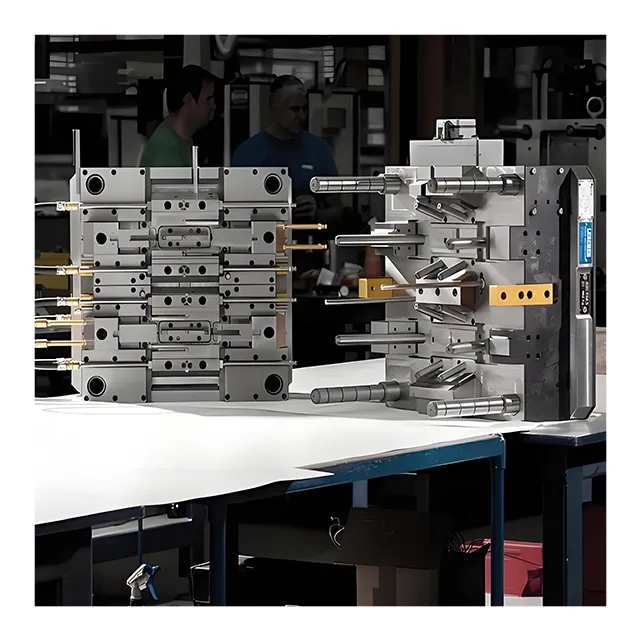

Injection molds for action figure models / cosmetic tubes

|

Attribute Category

|

Specific Information

|

|

Product Name

|

Plush Model Injection Molds

|

|

Applicable Products

|

Anime figures, trendy plush toys, collectible models, promotional gift models, etc.

|

|

Mold Material

|

High-quality mold steel (NAK80, S136) + corrosion-resistant alloy inserts (for special surface treatment needs)

|

|

Cavity Design

|

Multi-component combined cavity (supports detachable head-body and movable joint structures), precision ±0.005mm

|

|

Surface Treatment

|

Mirror polishing (Ra≤0.02μm), texture etching (supports skin texture/clothing pattern/metal plating effects)

|

|

Special Processes

|

Multi-color co-injection technology (supports one-step molding of 3+ colors), soft TPE overmolding (for elastic joint components)

|

|

Production Efficiency

|

Maximum single-mold capacity: 1,200 pieces/24 hours (subject to model complexity)

|

|

Quality Certifications

|

ISO 9001, Toy Safety Standards (EN71-3, ASTM F963)

|

Description

I. Dual-Category Product Overview

As a professional injection mold manufacturer, we specialize in developing high-precision molds for plush models and cosmetic tubes, providing end-to-end solutions from conceptual design to mass production for the toy & cultural creativity industry and beauty & personal care sector. Leveraging advanced mold technology and strict quality control, our molds enable extreme detail reproduction for plush models while meeting the dual requirements of functionality and aesthetics for cosmetic tubes, helping customers create competitive products.

II. Core Technical Advantages

(1) Plush Model Molds – Precision Defines Artistry

- Micron-Level Precision ControlUsing Japanese imported slow wire EDM and 5-axis CNC machining centers, we achieve 0.005mm-level precision, perfectly reproducing subtle features such as facial expressions, clothing folds, and weapon textures. The innovative split-cavity design supports precise molding of movable joints and detachable components, ensuring smooth articulation without sticking after assembly.

- Integrated Multi-Surface ProcessesOur proprietary texture etching technology replicates over 100 textures including skin pores, fabric weaves, and metal brushing. Combined with multi-color co-injection, it achieves complex color effects like gradient hair and iris patterns. For high-end collectibles, we offer gold/silver electroplating and pearlescent coating solutions to create museum-grade finishes.

- Efficient Production SolutionsOptimized runner systems reduce cycle time by over 30%, paired with automated demolding mechanisms to minimize manual intervention losses. Supporting quick mold change technology (single-mold change <15 minutes), we meet the flexible production needs of the trendy toy market for multi-SKU, small-batch orders.

(2) Cosmetic Tube Molds – Function Meets Aesthetics

- Aseptic Production DesignUsing food-grade stainless steel and mirror-polished inner walls (Ra≤0.01μm), combined with antibacterial mold coatings, we eliminate material residue and bacterial growth from the source, complying with pharmaceutical-grade hose production standards. The specially designed spiral runner system ensures uniform filling of high-viscosity pastes, preventing air bubbles and sink marks.

- Intelligent Functional StructureOur innovative adaptive sealing technology uses pressure sensors to dynamically adjust nozzle sealing parameters, ensuring consistent thread fitting precision and sealing performance across batches. It supports special-shaped nozzle designs (bevel, curved, serrated) to fit pumps, scoops, and other functional accessories.

- Lightweight & Energy-Saving TechnologyMoldflow analysis optimizes wall thickness distribution, reducing hose weight by 15%-20% without compromising strength, lowering raw material costs. Efficient conformal cooling channels shorten cooling time by 40%, enabling over 50 cycles per minute with high-speed injection machines.

III. Application Scenarios & Solutions

(1) Plush Model Mold Applications

- Toy Manufacturing: Anime IP derivatives, blind box figures, building block models

- Cultural Creativity: Movie & TV peripheral collectibles, corporate mascots, festival-limited gifts

- Education Sector: Science teaching aids, 3D printing prototype molds (supports multi-material molding: resin/ABS/TPU, etc.)

(2) Cosmetic Tube Mold Applications

- Skincare: Sunscreen hoses, hand cream tubes, essence soft packaging

- Color Cosmetics: Lip gloss tubes, concealer tubes, liquid eyeshadow pens

- Personal Care & Medical: Toothpaste tubes, ointment tubes, hair wax/gel hoses

IV. End-to-End Customization Services

- Pre-Development

- Plush Models: 3D scanning reverse engineering, movable joint mechanical analysis, color effect sampling

- Cosmetic Tubes: Nozzle sealing testing, material compatibility analysis (supports 10+ plastic materials: PE/PP/PETG, etc.)

- Manufacturing Control

- Key Processes: Cavity heat treatment hardness testing (HRC52-56), mold core precision CMM measurement (error <0.003mm)

- Trial Molding: Free 500-piece first-sample testing including dimensional reports, appearance defect analysis, and mass production efficiency evaluation

V. Collaboration Advantages

- Dual-Domain Expertise: Over 10 years in toy molds and 8 years in beauty packaging molds

- Global Certification System: Compliant with both European/US toy safety standards and cosmetic contact material regulations

- Flexible Production Capacity: Supports full-spec customization from single-cavity sampling molds to 16-cavity high-speed production molds

Choosing us means more than just acquiring a mold – it’s about gaining an efficient transformation solution from creativity to product. We look forward to partnering with you to bring every design to life and create industry-leading masterpieces.