Low Price Cnc Turning Milling Steel Aluminum Precision Frame Parts

Place of Origin : Fujian, China

Type : Milling, Turning

Micro Machining or Not : Micro Machining

Model Number : CMP-319

Brand Name : JSD

Product name : Cnc Turning Machining Custom Made Service

Material : Customers’ Requirement

Surface treatment : Painting\Powder Coating\Plating\Polishing

Process : CNC Turning Milling

Service : Customized OEM

Equipment : 3/4/5 Axis CNC Machining Center

Size : Customizesd Size

Drawing Format : 2D/(PDF/CAD/DWG/DXF)3D(IGES/STEP/VDA)

Certification : ISO9001

OEM/ODM : OEM ODM Non-standard Processing

Description

Product Specs (The Good Stuff)

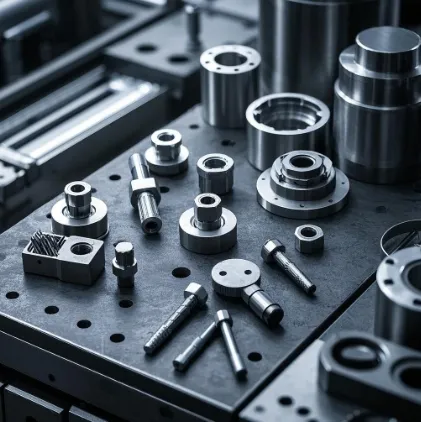

Material Options

Aluminum 6061/7075, Steel 1045/4140, Stainless Steel 304/316 – bro, we got all the good metals!

Tolerance

Up to ±0.005mm – that’s like, super tight! Your parts will fit better than a puzzle piece.

Surface Finish

Ra 0.8μm max – smooth as a baby’s bottom, no joke!

Lead Time

3-15 days depending on quantity – we don’t mess around with slow delivery!

How We Make These Bad Boys

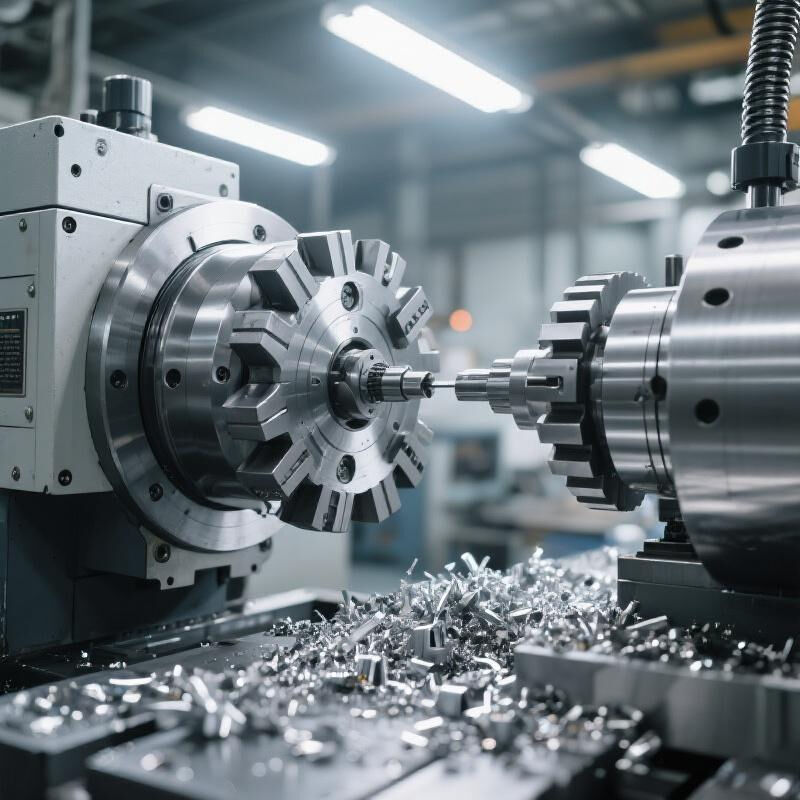

CNC Turning Process

Okay, so here’s the deal: we spin the metal at high speeds (like, really fast) and use cutting tools to shape it into cylindrical parts. It’s like a pottery wheel but for metal, and way more precise!

For aluminum, we can run at 3000+ RPM – that’s quick enough to make your head spin! Steel needs a bit more care, but we still get that perfect finish every time.

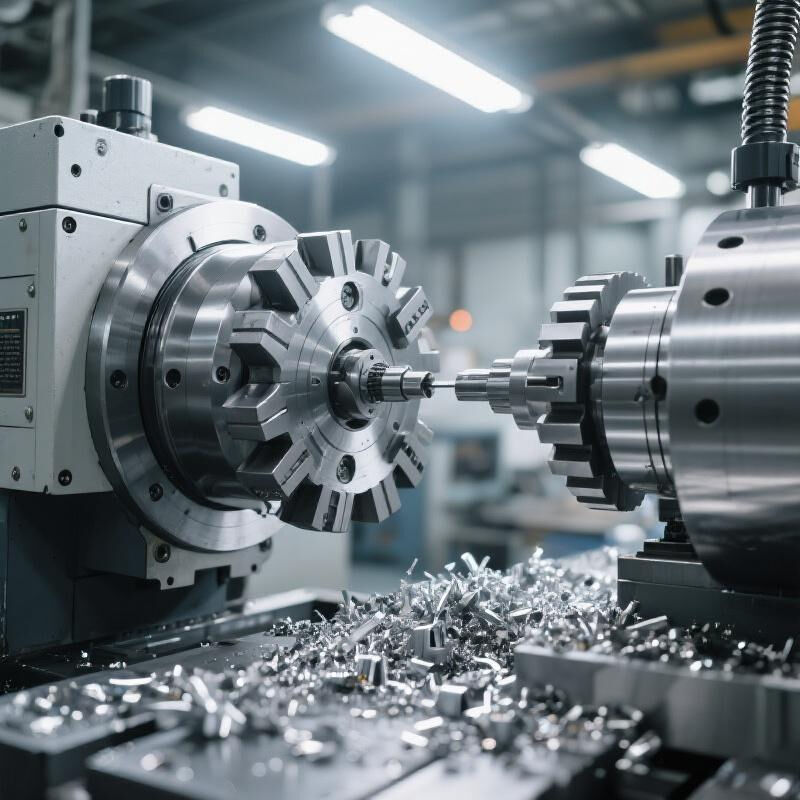

CNC Milling Process

This is where we get fancy with complex shapes. We use rotating cutters to remove material and create all those cool features like holes, slots, and pockets.

Our 5-axis machines can reach every angle – no more “we can’t make that shape” excuses! We’ve made parts that look like they came from a sci-fi movie.

Material Deep Dive (Nerd Alert)

Aluminum 6061

Pros: Lightweight, corrosion-resistant, cheap – perfect for most projects!

Cons: Not the strongest, but who needs that for most stuff?

Yield Strength: 276 MPa (test data, for reference only)

Steel 1045

Pros: Strong, durable, cheap – the workhorse of metals!

Cons: Heavy, rusts if you don’t protect it

Tensile Strength: 600 MPa (test data, for reference only)

Stainless Steel 304

Pros: Corrosion-resistant, strong – perfect for harsh environments!

Cons: Expensive, harder to machine

Hardness: 187 HB (test data, for reference only)

We Don’t Mess Around With Quality

ISO 9001:2015

Quality management system certified – we know what we’re doing!

IATF 16949:2016

Automotive quality standard – your car parts will be A+ grade!

AS9100D

Aerospace certified – we make parts that can fly (literally)!

Testing & Inspection (The Proof)

Coordinate Measuring Machine (CMM): We check every dimension with this bad boy – accuracy up to 0.001mm!

Hardness Testing: Rockwell and Brinell tests to make sure your parts are tough enough (test data for reference only)

Surface Roughness Tester: We measure that smooth finish – no rough edges here!

Material Certification: Every batch comes with a certificate – no mystery metals here, bro!

Where You Can Use These Parts

Aerospace

Engine parts, landing gear components – these parts can go to space (no joke!)

Automotive

Suspension parts, engine brackets – your car will love these upgrades!

Medical

Surgical tools, equipment parts – precision matters when lives are on the line!

Robotics

Arm joints, gear housings – build the next generation of robots with our parts!

FAQs (You’re Welcome)

How much do these parts cost?

Depends on material, complexity, and quantity – hit us up for a quote, we won’t break the bank!

Can you make custom designs?

Absolutely! Send us your CAD files and we’ll make your wildest engineering dreams come true.

What’s the minimum order quantity?

No minimum! We’ll make 1 part or 10,000 parts – whatever you need, bro.

Do you offer surface treatments?

Heck yeah! Anodizing, powder coating, plating – we can make your parts look as good as they perform.

Ready to Get Your Parts Made?

Contact us today for a free quote – your project deserves the best!