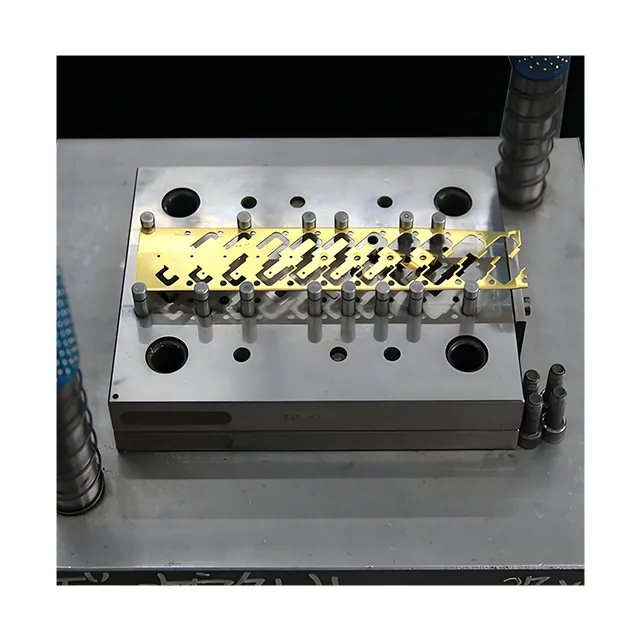

Metal Moulding Mould Maker Custom Hardware Mold

Place of Origin : Fujian, China

Type : Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM

Micro Machining or Not : Micro Machining

Model Number : IM-73

Brand Name : JSD

Product name : Precision Metal Parts Stamping Mold Service

Material : Customers’ Requirement

Surface treatment : Painting\Powder Coating\Plating\Polishing

Process : Cnc Machining+deburrs

Service : Customized OEM

Equipment : 3/4/5 Axis CNC Machining Center

Size : Customer Size

Drawing Format : 2D/(PDF/CAD/DWG/DXF)3D(IGES/STEP/VDA)

Certification : ISO9001

Tolerance : 0.01- +/-0.005mm

This product is designed to meet the individual needs of all kinds of hardware manufacturing enterprises, adopting advanced production technology and high-quality materials to ensure that each stamping can achieve extremely high precision and stability.

Description

Product introduction

This product is designed to meet the individual needs of all kinds of hardware manufacturing enterprises, adopting advanced production technology and high-quality materials to ensure that each stamping can achieve extremely high precision and stability. Whether it is automotive parts, electronic product shells, or household appliances accessories, our molds can bring unprecedented efficiency and quality improvement to your production line.

Product Specification

Size range: can be customized according to the specific needs of customers, supporting the production of molds from tiny precision parts to large-sized parts.

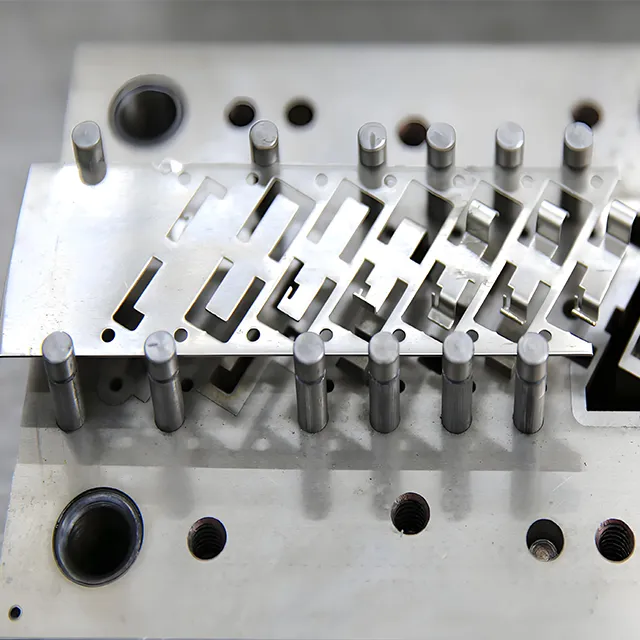

Precision level: ±0.01mm high precision, to ensure the accuracy and consistency of product dimensions.

Mold life: Depending on the material and frequency of use, the design life of the mold can reach tens of thousands to millions of stampings.

Applicable materials: including but not limited to stainless steel, aluminum alloy, copper alloy, carbon steel and many other metal materials.

Product Material

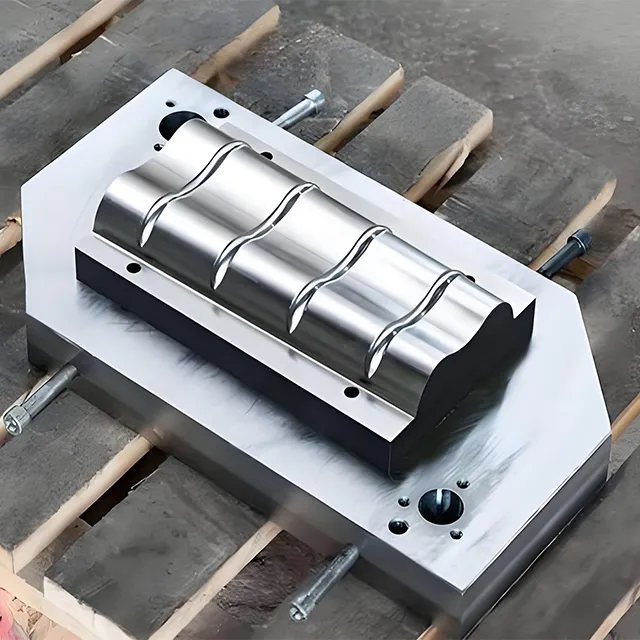

We select high quality die steel as the base material, such as SKD11, DC53, H13, etc. These materials have high hardness, wear resistance and thermal stability, which can effectively resist wear and deformation during the stamping process, and prolong the service life of the dies. Meanwhile, according to the specific needs of customers, special alloy materials can be selected to meet the requirements of use in specific environments.

Product Process

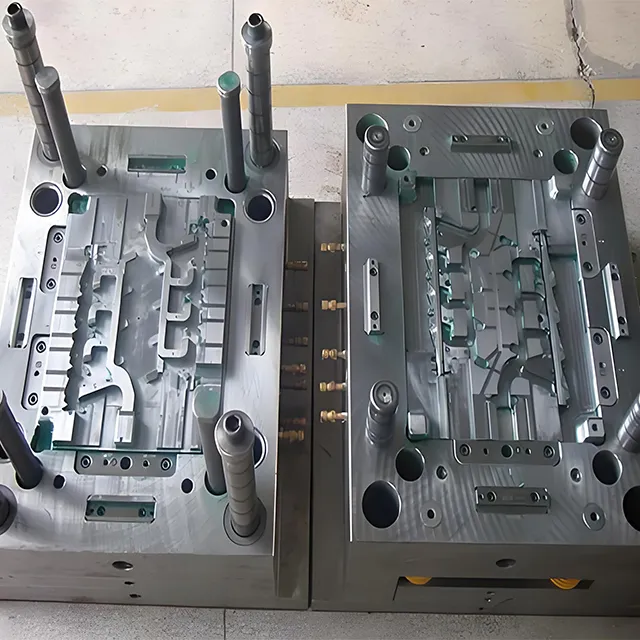

CAD/CAM design: Using advanced 3D modeling software, accurate design simulation is carried out according to the product drawings or samples provided by customers.

Precision machining: Using high-precision CNC machine tools (CNC), wire cutting, EDM and other processes to ensure the dimensional accuracy and surface quality of the mold parts.

Heat treatment: After quenching, tempering and other processes to improve the hardness and toughness of the mold, to ensure the stability and durability of long-term use.

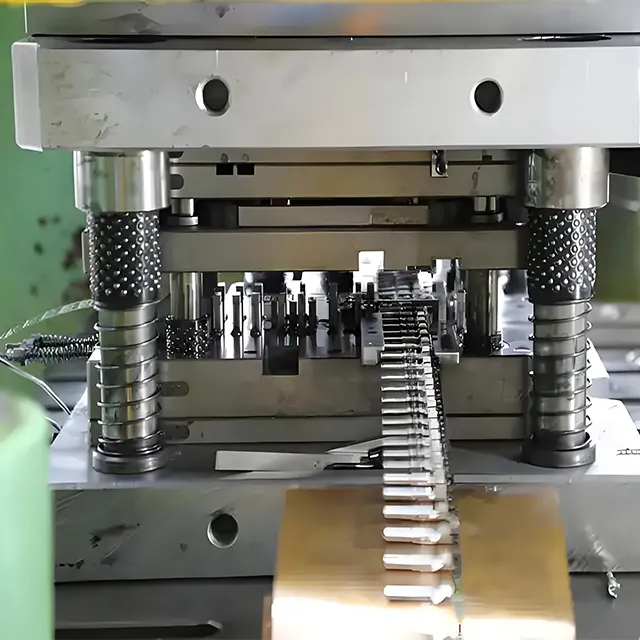

Assembling and debugging: Precise assembling and debugging by experienced technicians to ensure the smooth running of the mold and the best stamping effect.

Automobile manufacturing: used to manufacture automobile parts, such as engine covers, door panels, chassis parts, etc.

Electronic communication: precision stamping and molding of cell phone shells, tablet PC back covers, precision connectors, etc.

Household appliances: the production of inner shells and parts for home appliances such as refrigerators, washing machines, air conditioners, etc.

Aerospace: Manufacturing of precision parts, parts with extremely high requirements for material strength and precision.

Product customization

We offer a full range of customization services, including but not limited to:

Shape and size: Customized exclusive mold shape and size according to your product design needs.

Mold type: single punch, continuous mold, composite mold and many other types to choose from.

Special requirements: such as surface treatment (mirror polishing, anti-rust treatment), special structural design, etc., can be customized according to your needs.

Frequently Asked Questions

Q1: How long does it take to customize the mold?

A: The lead time for customization usually depends on the complexity and size of the mold, usually between 2-6 weeks, we will provide a detailed delivery schedule according to your specific needs.

Q2: What is the warranty policy of the molds?

A: We provide one year free warranty service for each set of molds, including but not limited to wear and tear repair and structural adjustment under normal use.

Q3: How to ensure the precision and life of the mold?

A: From material selection to processing and production, each step strictly follows the industry standards, and through precision testing and quality control system, we ensure the high precision and long life of the molds.

Q4: How to start the customization process?

A: Simply contact our customer service team, provide your design drawings or samples, as well as specific usage requirements, and our professional engineers will customize the best solution for you.

Act now to add an efficient and accurate customized hardware stamping die to your production line, so that quality and efficiency can go hand in hand! If you have any questions or need further information, please feel free to inquire.