Nylon Rubber Abs Injection Molding Plastic Inject Molding Service

| Attribute Category | Detailed Information |

|---|---|

| Product Type | Nylon rubber injection molding, ABS injection molding, plastic injection molding services |

| Core Materials | Nylon (PA), rubber (natural rubber, synthetic rubber, etc.), ABS (Acrylonitrile Butadiene Styrene copolymer), compatible with various engineering plastics and special modified materials |

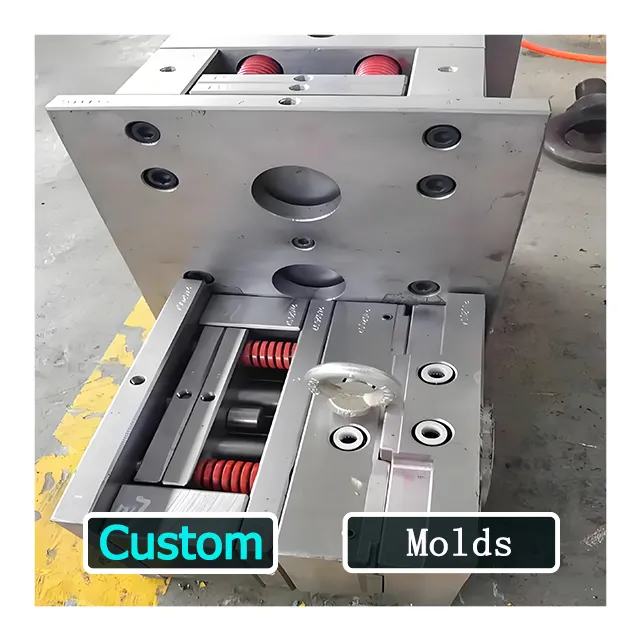

| Molding Process | High-precision injection molding process, covering thermoplastic injection and rubber injection, supporting complex processes such as multi-cavity molds, precision insert molding, and two-color injection molding |

| Technical Parameters | – Dimensional accuracy: Up to IT7-IT8 grade, ±0.01mm for some precision parts – Surface roughness: Ra≤0.8μm (adjustable according to product requirements) – Mold life: ≥500,000 cycles for standard molds, ≥1,000,000 cycles for precision molds |

| Technical Advantages | – Independent R&D of mold intelligent design system combined with Moldflow mold flow analysis to predict molding defects in advance – Equipped with servo-electric injection molding machines with clamping force of 50-3000 tons, supporting high-speed and high-pressure molding – Material modification laboratory capable of customizing special-performance materials such as high-temperature resistant (200℃+), low-temperature resistant (-40℃), conductive, and flame-retardant |

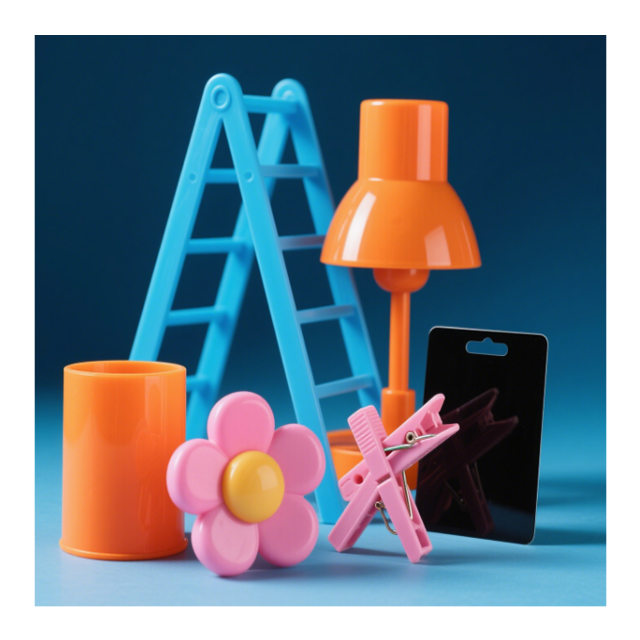

| Application Fields | Automotive components (e.g., nylon gears, ABS interior parts), electrical and electronics (rubber seals, ABS casings), medical devices (precision plastic parts), industrial equipment, consumer goods, etc. |

| Customization Services | Full-process customization from product design, mold development to mass production, supporting drawing/sample processing, small-batch trial production, and large-scale mass production |

| Service Process | Requirement communication → Solution design → Mold manufacturing → Sample confirmation → Mass production → Quality inspection → Logistics delivery |

Description

1. Technological Empowerment: Redefining the Heights of Injection Molding

2. Full-Process Technical Advantages: Crafting Exceptional Product Quality

① Precise Mold Design: The Pinnacle of Precision

② Material Innovation: Meeting Diverse Needs

③ Intelligent Production: Efficient, Stable, and Reliable

3. Wide Application Fields: Expert in Customized Solutions

4. Partner with Us for a Shared Future