PP (polypropylene) Plastic Injection – Molded Parts

| Parameter | Capability |

|---|---|

| Mold Base Standards | HASCO • DME • LKM |

| Steel Grades | NAK80 • S136 • P20 • H13 (HRC 48-52) |

| Tolerance Accuracy | ±0.005mm (Core/Cavity) |

| Max Mold Size | 800×600×300mm |

| Surface Finish | SPI A1 (Ra 0.012μm) • EDM Texturing |

| Hot Runner Systems | Mold-Masters |

| Lifespan | 500,000+ shots (Production Molds) |

| Lead Time | 15-25 Days (Standard) • 7 Days (Rush) |

| Certification | ISO 9001 • IATF 16949 |

| Min. Part Wall Thickness | 0.15mm |

Description

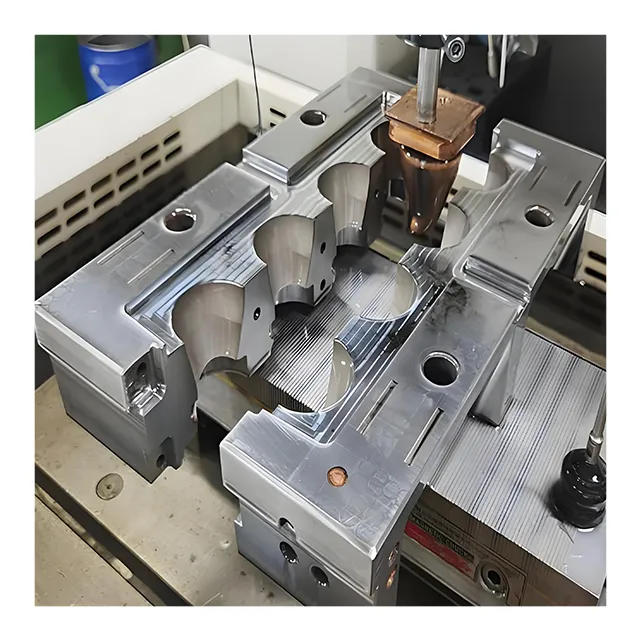

Specializing in high-precision insert injection molds, we deliver turnkey solutions for complex multi-material components requiring metal-plastic integration. Our German-designed mold shop combines Röders RP five-axis machining centers with AgieCharmilles EDM technology, achieving micron-level accuracy for medical devices, automotive connectors, and micro-electronics packaging.

Core Technical Capabilities:

• Insert Molding Expertise: Overmolding of brass terminals, ceramic substrates, and PCB assemblies with ±0.02mm positional accuracy

• Micro-Mold Manufacturing: Gates down to 0.1mm for microfluidic chips and connector pins

• Conformal Cooling: 3D printed cooling channels following cavity contours (40% cycle time reduction)

Advanced Engineering Process:

-

Design Phase:

-

Moldflow analysis for warp prediction and gate optimization

-

DFM reports with draft angle and wall thickness recommendations

-

-

Precision Machining:

-

Hard milling (HRC 62) with <1μm surface roughness

-

Coordinate grinding for slide fits <0.003mm clearance

-

-

Validation:

-

Optical comparators for profile verification

-

Trial shots with CMM inspection reports

-

Material-Specific Solutions:

-

Engineering Plastics: PEEK, PEI (Ultem®), PPSU molds with hardened cores

-

Liquid Silicone Rubber (LSR): Cold runner systems with vacuum venting

-

Bio-Polymers: FDA-compliant tooling with easy-demold features

Industry Applications:

✓ Medical: Overmolded surgical instruments with embedded RFID tags

✓ Automotive: Waterproof connectors with integrated seals (IP68)

✓ Consumer Electronics: Thin-wall housings (<0.4mm) with metalized logos

✓ IoT Devices: Antenna integration through in-mold labeling

Quality Assurance Protocol:

-

Steel certification: Traceable mill test reports

-

Tool tryout: 3-stage sign-off (T0/T1/T2)

-

Production monitoring: Cavity pressure sensors

-

Documentation: Full PPAP packages available

Technical Advantages:

• Zero-sink marks through sequential valve gating

• Automatic insert feeding systems for high-volume production

• Collapsible cores for internal undercuts

• Quick-change insert systems for family molds

Value-Added Services:

-

Free material selection consultation

-

Rapid prototype molds (5-7 days) for design validation

-

In-house injection molding production (50-650 ton presses)

-

Mold maintenance programs with digital health monitoring

Describe your part requirements and annual volume below – our mold engineers will provide technical solutions within 8 working hours!