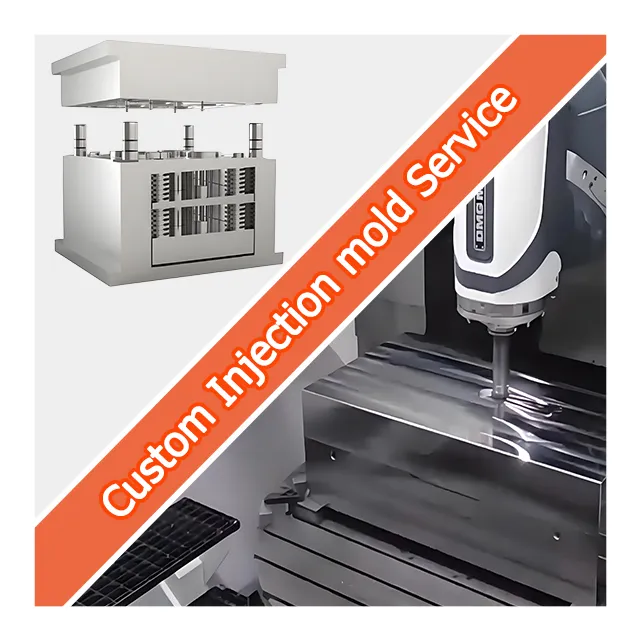

Professional injection Manufacture Plastic Injection Molding Parts Service

Place of Origin : Fujian, China

Brand Name : JSD

Model Number : IM-76

Product Material : Steel

Product : Injection Mould

Product Name : Injection Mould

Shaping Mode : Plasitc Injection Mould

Material : Stainless Steel

Size : Customized Size

Color : Customized Colors

Service : Customized OEM

Drawing Format : 2D/(PDF/CAD)3D(IGES/STEP)

Certification : ISO9001

Keyword : Mould

MOQ : 1piece

Description

I. Service Introduction

Welcome to our custom plastic part injection molding service page! We focus on providing you with high-quality and high-precision plastic part injection molding solutions to meet your diverse needs in different industries and application scenarios.

II. Custom Service Highlights

Personalized Customization Plan

Deeply understand your product design concept, performance requirements and application environment, and tailor exclusive injection molding solutions for you.

Whether it is small and precise components or large and complex structures, we can precisely create them.

Professional Team Collaboration

Have an elite team composed of experienced engineers, designers and technicians.

From project initiation to delivery, team members closely cooperate to ensure that each link meets your expectations.

Extensive Material Selection

Provide a rich variety of plastic materials, including but not limited to general-purpose plastics (such as polyethylene, polypropylene, polystyrene), engineering plastics (such as nylon, polycarbonate, polyester) and special plastics (such as polyetheretherketone, liquid crystal polymer).

Recommend the most suitable materials for you based on your product characteristics and usage conditions to achieve the best balance of performance, cost and quality.

III. Service Advantages

Excellent Precision and Quality

Adopt advanced injection molding equipment and precision molds to ensure that the dimensional accuracy and consistency of plastic parts reach an extremely high level.

A strict quality control system runs throughout the entire production process, from raw material inspection to finished product testing, to ensure that each plastic part meets strict quality standards.

Efficient Production Capacity

Equipped with multiple modern injection molding production lines, it can quickly respond to your order requirements and realize large-scale production or small-batch customization.

Optimized production processes and efficient supply chain management shorten the production cycle and bring your products to the market faster.

Innovative Design Support

Use advanced design software and simulation technology to simulate and analyze the injection molding process, predict potential problems in advance and optimize the design plan.

Provide you with innovative structural design and process improvement suggestions to improve product performance and reduce costs.

Cost-effectiveness Optimization

Through reasonable mold design, material selection and production process arrangement, help you minimize production costs while ensuring quality.

Provide flexible pricing strategies to meet the project needs of different scales and budgets.

IV. Production Process

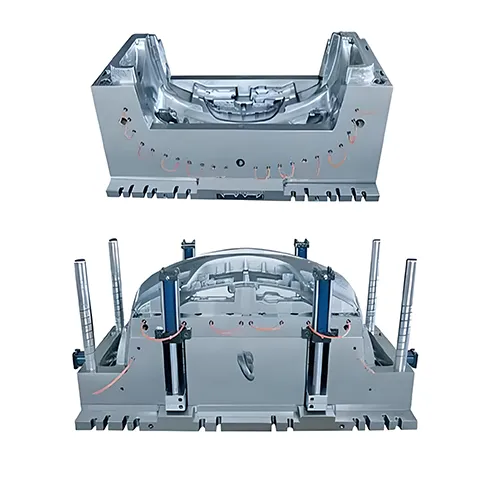

Mold Manufacturing

Use high-precision processing equipment and advanced mold manufacturing technology to create injection molds with precise structure and long service life.

The mold design fully considers the requirements of the injection molding process, such as runner balance and cooling system optimization, to improve production efficiency and product quality.

Injection Molding

Adopt advanced injection molding machines to precisely control injection parameters, such as injection pressure, speed, temperature and time, to ensure that the plastic melt evenly fills the mold cavity.

Strictly monitor the production process and adjust process parameters in a timely manner to meet the requirements of different materials and product structures.

Post-processing and Assembly

Provide post-processing processes such as trimming flash, drilling, tapping, printing, coating, etc. according to product requirements.

Have the assembly capability to assemble injection-molded parts into complete products and provide you with one-stop service.

V. Processing Equipment

High-Precision Injection Molding Machines

Have various models such as all-electric, hydraulic hybrid and large injection molding machines to meet the production of plastic parts with different sizes and precision requirements.

The injection molding machines are equipped with advanced control systems, which can achieve precise process parameter control and stable production operation.

Mold Processing Equipment

Include high-speed milling machines, electrical discharge machines, wire cutting machines, etc., to ensure the manufacturing accuracy and surface quality of the molds.

Regularly maintain and upgrade the equipment to maintain the high performance and stability of the equipment.

VI. Application Fields

Our custom plastic part injection molding service is widely used in the following fields:

Automotive Industry

Produce automotive interior parts, exterior parts, engine components, electronic accessories, etc.

Meet the performance requirements of the automotive industry for plastic parts, such as high strength, wear resistance and high temperature resistance.

Electronic Appliances

Manufacture electronic product housings, connectors, insulation parts, buttons, etc.

Ensure that the plastic parts have good electrical insulation performance and antistatic performance.

Medical Equipment

Customize plastic components in medical devices, such as syringes, infusion sets, surgical instrument handles, etc.

Comply with strict medical industry standards and regulations to ensure the safety and reliability of the products.

Consumer Goods

Provide beautiful and practical plastic parts for household items, toys, office supplies, packaging containers, etc.

Meet consumers’ diverse needs for product appearance and quality.

Whether you are a start-up enterprise or an industry giant, we will serve you wholeheartedly and provide you with the highest quality custom plastic part injection molding solutions for your projects! Looking forward to working with you to create a bright future!