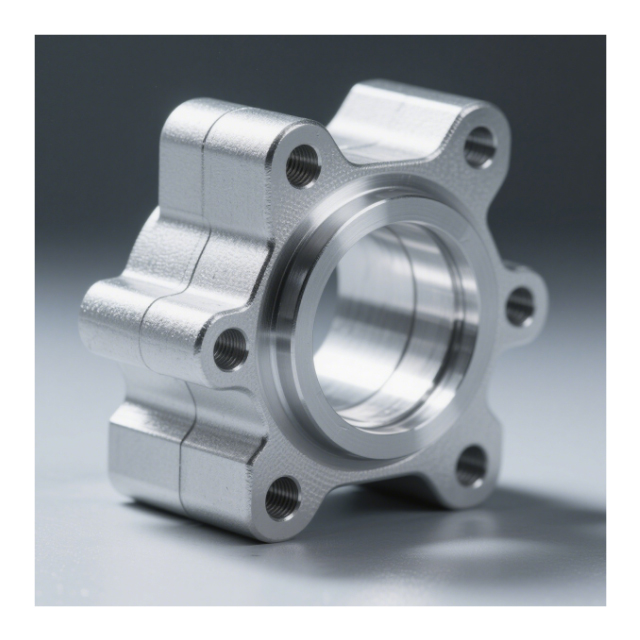

Stainless Steel Die-Cast Parts Machining Services

Processing materials: 304/316L/410/420/17 – 4PH, etc.

Shape range: 500×400×300mm (customizable)

Wall thickness accuracy: minimum 0.8mm (complex parts) / 1.2mm (customizable)

Weight range: within 15kg (solid parts) / within 8kg (customizable)

Tolerance standard: GB/T 6414 CT4 – CT6 level (customizable)

Surface roughness: Ra≤1.6μm (polished surface) / Ra≤3.2μm (conventional surface) | customizable

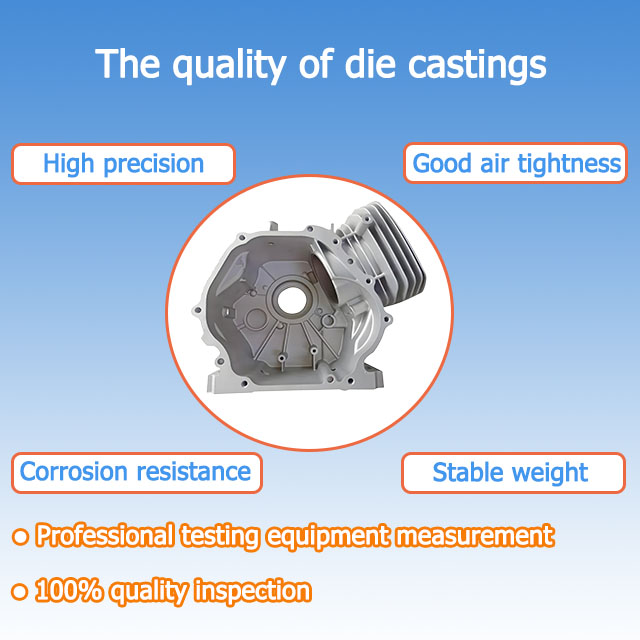

High precision: Coordinate measuring machine detection accuracy of ±0.005mm, 100% full inspection for the first piece

Long lifespan: H13 mold lifespan ≥ 100,000 times, 20% higher than the industry average

Low defect rate: Air tightness test at 0.8MPa with 30 – second pressure holding and no leakage, defective rate ≤ 0.3%

Description

🔥 Why Choose Us? 3 Core Advantages That Solve Key Pain Points

🛠️ Full-Dimension Customization, Your Requirements Set the Standard

1. Material Customization: 3 Series for All Scenarios

|

Material Type

|

Representative Grades

|

Core Performance Data

|

Typical Applications

|

|

Austenitic Stainless Steel

|

304/316L

|

Salt spray test ≥1000 hours, elongation ≥40%

|

Food machinery, medical equipment, kitchen & bathroom hardware

|

|

Martensitic Stainless Steel

|

410/420

|

Tensile strength ≥540MPa, hardness HRC 20-25

|

Automotive brake calipers, industrial valve components

|

|

Precipitation Hardening Stainless Steel

|

17-4PH

|

Hardness HRC 30-40, yield strength ≥1000MPa

|

Aerospace structural parts, precision instrument components

|

2. Dimensional Processing: Micron-Level Precision, Pushing Technological Limits

- Size Range:Maximum 500×400×300mm (L×W×H), minimum detail precision 0.1mm

- Wall Thickness Control:1.2mm for regular parts, 0.8mm for complex structures (industry average 1.5mm)

- Tolerance Standard:GB/T 6414 CT4 level (higher CT6 level available), surface roughness Ra≤1.6μm (polished surface)

- Weight Range:Within 15kg for solid parts, 8kg for hollow structures, lightweight design optimization supported

3. Surface Treatment: 8 Processes for Both Aesthetics and Performance

|

Process Type

|

Performance Parameters

|

Effect Description

|

Application Scenarios

|

|

Mechanical Polishing

|

Mirror-level Ra≤0.2μm, gloss ≥85%

|

Mirror-smooth surface

|

Medical devices, high-end consumer electronics casings

|

|

Electroplating/Chemical Plating

|

Nickel plating salt spray test ≥500 hours, chromium plating ≥1000 hours

|

Long-lasting anti-corrosion with metallic luster

|

Outdoor equipment, decorative hardware parts

|

|

PVD Coating

|

Hardness HV 2000+, friction coefficient ≤0.15

|

Wear-resistant and scratch-resistant

|

Mold components, high-precision mechanical parts

|

|

Passivation Treatment

|

Blue spot test rust-free, passivation film thickness 2-5μm

|

Original color protection with enhanced corrosion resistance

|

Food-grade equipment, chemical pipeline components

|

4. Process Assurance: Hardcore Technology for Quality

- Mold Technology:Using H13/8407 mold steel (service life ≥100,000 cycles), CAE mold flow analysis optimizing gate design, reducing porosity by 40%

- Casting Equipment:200T-2000T cold chamber die casting machines, 1650℃ precise temperature control, grain refinement increased by 30% (vs. traditional processes)

- Inspection System:CMM (accuracy ±0.005mm) + industrial CT (internal defect resolution 0.1mm), dual control with first-piece full inspection + production sampling

🚀 4 Industry-Tailored Solutions, Deep Customization for Niche Scenarios

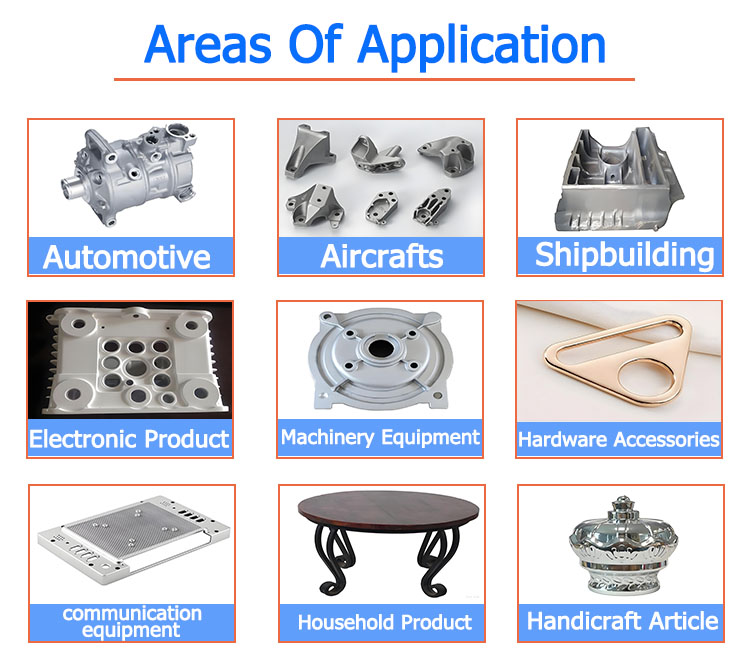

1. Automotive Components

2. Medical Devices

3. Industrial Equipment

4. 3C Electronics

💎 Transparent End-to-End Service, Traceable Every Step

- Requirement Communication:24-hour response, free DFM (Design for Manufacturability) analysis (including material suggestions + cost optimization)

- Prototyping Stage:7-15 days for first sample delivery, 3 free revisions supported, with full-dimension inspection report

- Mass Production Stage:500-piece MOQ, weekly production updates, SF Express shipping + wooden frame packaging (damage compensation guaranteed)

- After-Sales Guarantee:1-year warranty (free repair for non-human damage), 7×12-hour dedicated customer service for fast response