Tailor-made automotive parts CNC wear-resistant cast iron precision machining parts

Place of Origin: Fujian, China

Type: Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Micro Machining or Not: Micro Machining

Model Number: CMP-23

Brand Name: JSD

Product name: cnc metal parts

Material: Stainless steel/aluminum/brass nylon

process: Milling turning

Color: Silver OR Customer’s Demand

Surface treatment: Painting\Powder Coating\Plating\Polishing

Service: OEM ODM Customised

Keyword: cnc machining parts

Size: 1-1000mm

MOQ: 1 Piece

OEM/ODM: OEM ODM Non-standard Processing

Description

Product Introduction

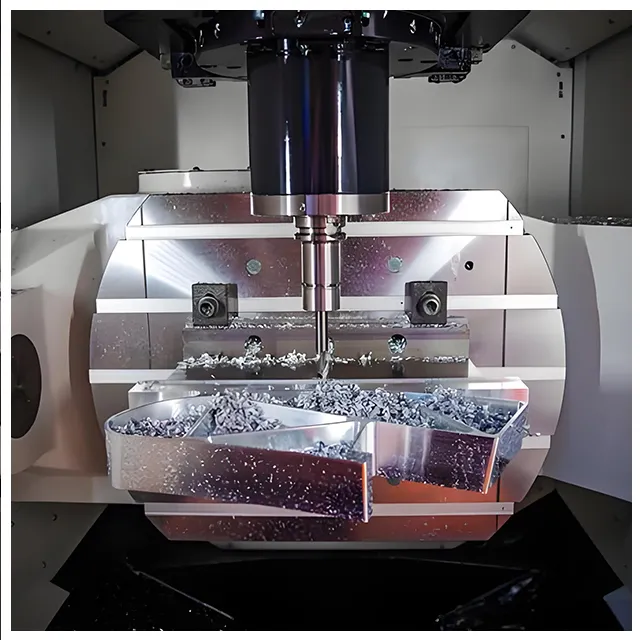

ANSHA customizes auto parts, using CNC (computer numerical control) technology to provide you with wear-resistant cast iron precision machined parts. Our products are suitable for the production of various auto parts, ensuring that your vehicle maintains excellent performance and long-lasting durability in harsh working environments.

Product Features

●Personalized customization: According to your specific needs, we provide one-to-one customization services to ensure that the size, shape and function of each part fully meet your specifications.

●Strong wear resistance: The use of high-quality wear-resistant cast iron materials effectively improves the service life of parts in high-speed and high-pressure environments.

●Precision machining: High-precision CNC machining technology ensures the dimensional accuracy and surface finish of parts to meet the high standards of the automotive industry.

●High strength: Cast iron materials have good mechanical properties and can withstand the high-intensity loads of auto parts at work.

●Good stability: The products undergo strict quality inspections to ensure stability and reliability in complex environments.

●Application scenarios: automotive engine parts, gearbox gears, suspension system components, brake system parts, wheel hub bearing seats, other automotive metal accessories

●Material selection: ductile iron, gray cast iron, malleable cast iron, wear-resistant alloy cast iron

Processing process

1. Design confirmation: Detailed analysis is carried out according to the design drawings or samples provided by the customer to confirm the processing plan.

2. Material preparation: Select high-quality cast iron materials and conduct necessary material performance tests.

3. CNC programming: Write CNC processing programs according to design drawings.

4. Precision processing: Use advanced CNC machine tools to process parts.

5. Quality inspection: Comprehensive inspection of size, shape, surface quality, etc. of the processed parts.

6. Surface treatment: Surface treatment such as grinding, polishing, and painting is carried out according to requirements.

7. Quality re-inspection: After completing all processing links, a final quality inspection is carried out.

8. Packaging and delivery: Professional packaging is used to ensure the safety of the product during transportation.

After-sales service

We provide comprehensive after-sales service, including product usage consultation, technical support, troubleshooting, and return and exchange services. We promise that all ANSHA products are produced according to the highest standards to ensure your satisfaction.

Contact XIAMEN GOLDCATTLE

If you have any customization needs or questions, please feel free to contact us. ANSHA is committed to providing you with the best quality products and the most professional services.