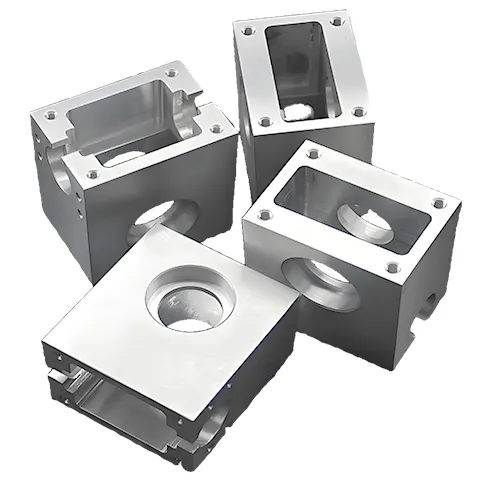

Precision CNC machining turning and milling blocks, aluminum alloy/stainless steel material professional customization

Place of Origin : XiaMen, China

Brand : JSD

Model : CNC-41

Type : Broaching, Drilling, Etching/Chemical Processing, Laser Processing, Milling, Other Processing Services, Turning, Wire Cutting, Rapid Prototyping Micromachining or Non-Micromachining.

Product Name : CNC Machine Tool Metal Parts

Material : Stainless steel/copper/aluminum alloy

Processing method : CNC center precision machining

Surface Treatment : Powder Coating, Anodizing, Aluminum Plating, Zinc Plating, etc.

Shape : According to your drawing

Sample time : 7-10 days

Packing : According to your requirement

Tolerance : +/- 0.005 mm

Production Quantity : 1 piece

Description

Product Description

Our precision CNC milling blocks are made of high-quality aluminum alloy and stainless steel materials, which are carefully designed and precisely processed for a variety of industrial applications. We provide comprehensive professional customization services to ensure that each milling block can meet your specific needs and specifications.

Product Features

1. High-precision processing: using advanced CNC processing technology to ensure the dimensional accuracy and surface finish of each part.

2. A variety of materials are available: aluminum alloy and stainless steel are available to meet the needs of different environments and working conditions.

3. Professional customization: one-to-one customization service is carried out according to the drawings or samples provided by customers to ensure the applicability and functionality of the parts.

4. Strong durability: The high-quality materials selected ensure the service life and wear resistance of the milling blocks.

5. Wide application: suitable for aerospace, automobile manufacturing, machinery manufacturing, electronic equipment and other industries.

Material specifications

●Aluminum alloy: 6061-T6, 7075-T6 and other commonly used aluminum alloy materials, lightweight and with good corrosion resistance.

●Stainless steel: 304, 316 and other stainless steel materials have strong corrosion resistance and are suitable for harsh environments.

Customization process

1. Demand communication: Communicate the needs with customers in detail, including material, size, tolerance and other requirements.

2. Design review: Design review and optimization based on the information provided by the customer.

3. Sample production: Make samples for customer confirmation and testing.

4. Mass production: After the sample is confirmed to be correct, enter the mass production stage.

5. Quality inspection: Strictly control the quality during the production process to ensure that each part meets the standards.

6. Packaging and delivery: Use safe packaging to ensure the safety of the product during transportation.

Contact us

If you are interested in our precision CNC machining turning and milling blocks, or have any customized needs, please feel free to contact us. Our professional team will provide you with the best service and support.