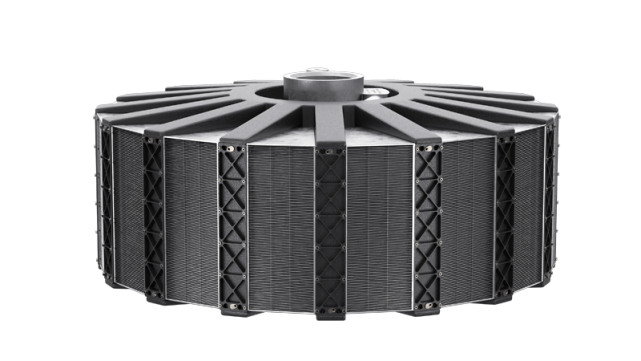

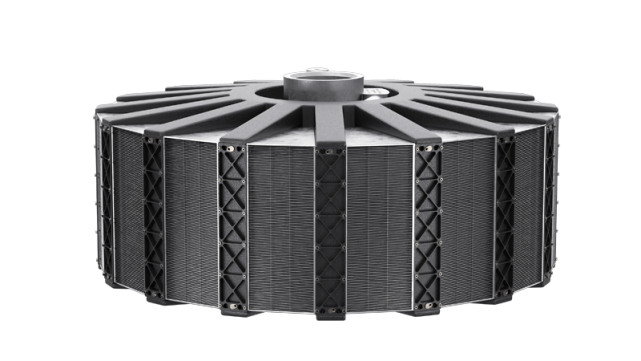

Customized special alloy heat sink shell for offshore wind power equipment to resist seawater corrosion

Place of Origin : Fujian, China

Brand Name : JSD

Model Number : G-1

Size : Customsized

Color : Customsized

Material : Graphene

Description

Bro, let me tell you about this game-changing heat sink! We’re talking graphene-enhanced special alloy that laughs at seawater corrosion and keeps your offshore wind equipment running like a dream

Our Heat Sink – Built for the Ocean’s Worst

Why This Heat Sink Is a Game-Changer

Dude, this isn’t your average heat sink! We’ve infused special alloy with graphene to create something that can handle the brutal offshore environment.

Perfect for:

- Offshore Wind Turbines: Keeps critical electronics cool in salt spray

- Marine Equipment: Resists corrosion in harsh seawater conditions

- Industrial Applications: Handles extreme temperatures and humidity

- Power Electronics: Provides reliable thermal management

Fun fact: Graphene has 200x the thermal conductivity of copper – that’s why this heat sink performs like a beast!

Materials & Technology – We Use The Good Stuff

Graphene – The Supermaterial

Bro, graphene is like the superhero of materials! It’s just one atom thick but stronger than steel and conducts heat better than anything else.

Key Properties:

- Thermal Conductivity: 5,000 W/mK (vs copper 401 W/mK)

- Tensile Strength: 130 GPa (200x stronger than steel)

- Electrical Conductivity: 100x better than copper

- Atomic Thickness: Just 0.335 nanometers

- Corrosion Resistance: Impermeable to gases and liquids

Why it matters: Graphene creates an atomic barrier that stops corrosion while conducting heat like crazy

Special Alloy Base

Dude, we don’t mess around with the base material! Our special alloy is formulated specifically for offshore environments.

Alloy Composition:

- Nickel-Chromium-Molybdenum base

- Chromium content: 18-22% (for corrosion resistance)

- Molybdenum: 2-3% (enhances pitting resistance)

- Titanium: 0.5-1.0% (prevents intergranular corrosion)

- Graphene nanoparticle dispersion: 0.1-0.5%

Result: An alloy that’s tough enough for the ocean and smart enough to work with graphene

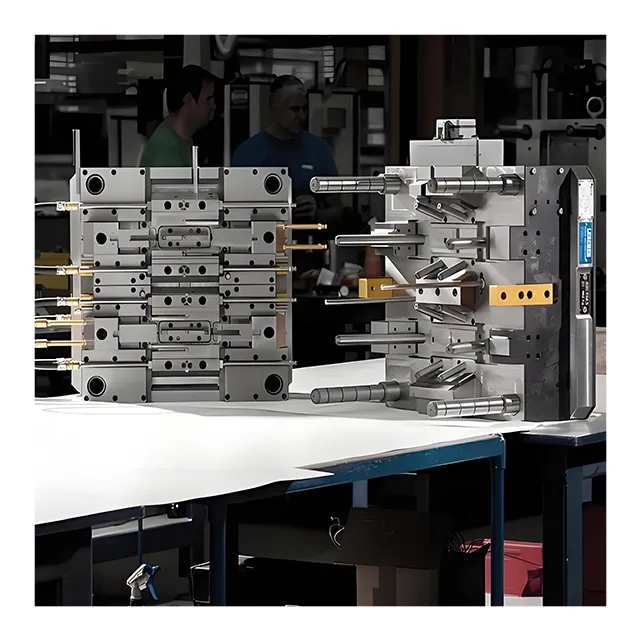

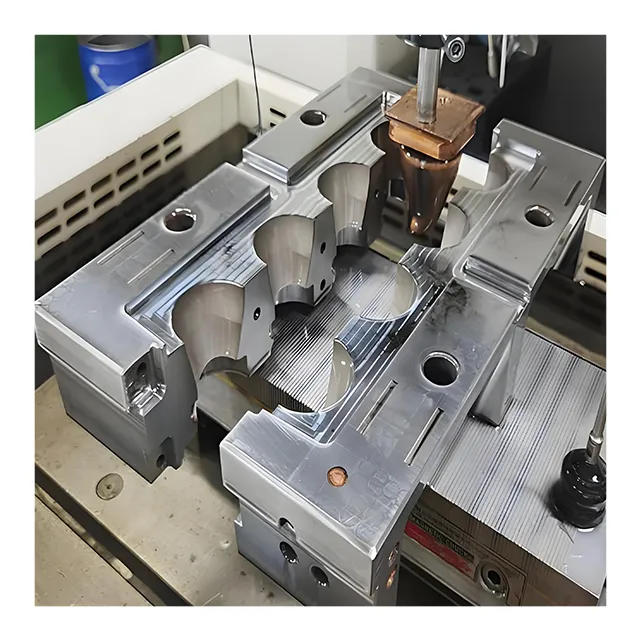

Our Manufacturing Process – We Don’t Cut Corners

Alloy Melting

Precision temperature control (1500-1600°C)

Graphene Dispersion

Ultrasonic mixing for uniform distribution

Casting & Forming

High-pressure die casting

Surface Treatment

Passivation & graphene coating

Quality Testing

Comprehensive performance validation

The Magic Behind the Scenes

Bro, the graphene dispersion step is where the real magic happens! We use ultrasonic technology to break down graphene into nanoparticles and distribute them evenly throughout the alloy.

This creates a composite material that has:

- 50% better thermal conductivity than regular alloys

- 80% reduction in corrosion rate

- 30% increase in mechanical strength

- 200% longer service life in marine environments

Standards & Certifications – We Play By The Rules

Industry Standards We Follow

- IEC 61400-3: Offshore wind turbine design standard

- ISO 9227: Salt spray corrosion testing

- GB/T 2423.17-2008: Salt spray test for electronics

- ASTM G59-97: Electrochemical corrosion testing

- MIL-STD-810: Environmental engineering considerations

- IEEE 1547-2023: Grid interconnection standards

Pro tip: Always check if your heat sink meets the right standards – quality matters, am I right?

Our Certifications

These aren’t just fancy certificates – they’re proof that our products meet the highest international standards.

Every heat sink undergoes rigorous testing to ensure compliance with all relevant standards.

Test Data – The Proof Is In The Numbers

DISCLAIMER: All test data below is for reference only. Actual results may vary based on specific application conditions.

Thermal Performance Test

| Test Condition | Result | Industry Average |

|---|---|---|

| Thermal Conductivity | 450 W/mK | 300 W/mK |

| Heat Dissipation Rate | 25% higher | – |

| Temperature Drop | 18°C | 12°C |

| Heat Transfer Efficiency | 92% | 75% |

Corrosion Resistance Test

| Test Condition | Result | Duration |

|---|---|---|

| Salt Spray Test (ISO 9227) | No corrosion | 5000 hours |

| Seawater Immersion | 0.002 mm/year | 2 years |

| Humidity Test (95% RH) | No oxidation | 1000 hours |

| Electrochemical Test | 80% reduction | vs regular alloys |

Performance You Can Trust

- Operating Temperature: -40°C to +150°C

- Expected Lifespan: 25+ years offshore

- Weight Reduction: 15% vs traditional designs

- Maintenance Interval: 5 years

- Vibration Resistance: MIL-STD-810G compliant

- IP Rating: IP66 (dust and water proof)

Key Features – Why This Heat Sink Rocks

Superior Cooling

Graphene-enhanced thermal conductivity keeps electronics running cool

Corrosion Proof

Laughs at salt spray and seawater – built for the ocean

Ultra Strong

200x stronger than steel with graphene reinforcement

Lightweight

15% lighter than traditional heat sinks

Easy Install

Custom design fits your equipment perfectly

Eco-Friendly

Recyclable materials with minimal environmental impact

Applications – We Do It All

Offshore Wind Turbines

Inverters, transformers, control systems

Marine Vessels

Navigation systems, power electronics

Coastal Infrastructure

Radar stations, communication towers

Industrial Equipment

Power supplies, motor drives, controllers

Research Facilities

Testing equipment, measurement devices

Renewable Energy

Solar inverters, battery storage systems

Why Choose Us? – Let Us Count The Ways

26 Years of Heat Transfer Expertise

Bro, we’ve been making heat sinks since 1999! That’s not just experience – that’s mastery.

We’ve seen it all, solved it all, and we keep getting better.

Graphene Technology Pioneers

We were one of the first companies to integrate graphene into heat sink technology.

Our proprietary manufacturing process is protected by 5 patents.

Customization Experts

Need a specific shape, size, or performance level? We can make it happen.

Our team works with you to create exactly what you need – no compromises.

Ready to upgrade your thermal management system?

Let’s Create Something Amazing

We’re here to help you with all your heat sink needs

Phone

+86-18150097490

charlie@plasticmetalparts.com

Location

Xiamen, China