Customized optical instrument high-precision injection molding parts

Place of Origin : Fujian, China

Brand Name : JSD

Model : IM-05

Plastic Modling Type : injection

Product name : Injection Molded ABS products

Material : ABS/POM/PA66/PP/PC/PA/PU/TPE/TPU etc

Drawing Format : STP. STEP . IGS

Process : Injection + Assembly + Packaging

Certification : ISO9001:2015

Color : White,Black,as request

Usage : Widely

Surface finish : Custom Surface Texture

Design : Customer Reqestment

Service : OEM\ODM

Description

Product Overview

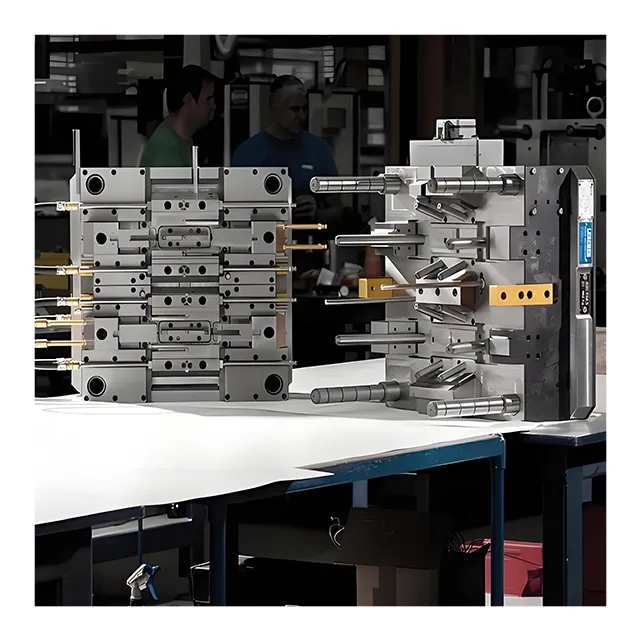

Introducing our cutting-edge Advanced Technology Custom Injection Molded Parts, designed to meet the most demanding specifications in the industry. Our focus on precision control and high-quality standards ensures that every part we produce exceeds your expectations. These parts are ideal for applications requiring intricate designs, tight tolerances, and durability in harsh environments.

Key Features

1.Precision Engineering: Crafted using state-of-the-art injection molding machines and precision tooling, our parts boast unparalleled dimensional accuracy and repeatability. Every aspect of the production process is carefully monitored and controlled to ensure that your parts meet or exceed your exact specifications.

2.High-Quality Materials: We source only the finest materials, including engineering-grade plastics and composites, to create parts that are built to last. These materials offer superior properties such as strength, durability, chemical resistance, and temperature stability, ensuring that your products perform optimally in even the most challenging conditions.

3.Customized Designs: With our in-house design and engineering capabilities, we can work closely with you to develop customized solutions tailored to your unique requirements. Whether you need complex geometries, intricate details, or tight tolerances, our team of experts has the skills and expertise to bring your vision to life.

4.Cost-Effective Production: We understand the importance of cost-efficiency in today’s competitive market. That’s why we optimize our production processes to minimize waste and maximize material usage, resulting in cost-effective solutions for large-volume production runs.

5.Rapid Prototyping & Testing: Our rapid prototyping capabilities allow us to quickly turn your designs into tangible prototypes for testing and validation. This accelerates the product development cycle and ensures that any necessary adjustments are made in a timely manner.

Product Applications

Our Advanced Technology Custom Injection Molded Parts are widely used across various industries, including but not limited to:

●Automotive (interior and exterior components, engine parts, etc.)

●Medical Devices (disposable items, surgical instruments, implants, etc.)

●Electronics & Consumer Goods (housings, enclosures, connectors, etc.)

●Aerospace & Defense (components for aircraft, satellites, missiles, etc.)

●Industrial Equipment (parts for machinery, tools, and automation systems)

Why Choose Us?

●Expertise & Experience: With years of experience in the injection molding industry, we have the knowledge and skills to deliver exceptional results.

●Innovative Solutions: We continuously invest in research and development to stay ahead of the curve and offer cutting-edge solutions to our clients.

●Quality Assurance: Our rigorous quality control processes ensure that every part meets or exceeds industry standards and your unique requirements.

●Customer Support: Our dedicated customer service team is always available to address your concerns and provide personalized support throughout the project lifecycle.

If you’re looking for Advanced Technology Custom Injection Molded Parts that combine precision control with high-quality standards, look no further. Our commitment to excellence, innovation, and customer satisfaction sets us apart in the industry. Contact us today to learn more about how we can help you bring your next project to life.