Customized anti-loosening brass screws and bolts for mechanical manufacturing

Place of Origin : Xiamen,China

Name : CNC Brass Threaded Fittings

Model : CNC-29

Material : Brass/steel/stainless steel/aluminum alloy etc.

Application : Connectors/Fasteners

Size : Customized

Shape : Customized

Application : As per customer’s request

Surface treatment : According to customer’s requirement

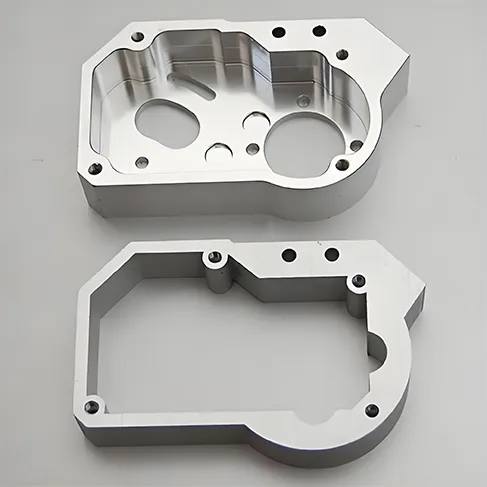

Processing Technology : CNC Processing such as Turning / Milling

Certification : ISO9001

Description

Product Highlights

In the pursuit of high efficiency, stability and durability in industrial environments, we are proud to launch industrial-grade custom brass screws. These screws are designed to withstand harsh working conditions, combining strong load capacity and excellent durability, becoming the preferred connection solution for many industries.

Core Features

1. Industrial-grade material: Select high-quality brass as the base material to ensure that the screws maintain stable physical and chemical properties in harsh environments.

2. Super strong load capacity: After precise calculation and testing, our brass screws can withstand loads far exceeding ordinary screws, ensuring the stability and safety of the equipment structure.

3. Excellent durability: Using advanced anti-corrosion treatment technology, it can effectively resist oxidation, corrosion and wear, extend the service life of the screws, and reduce maintenance costs.

4. Precise customization: According to the specific needs of customers, we provide a full range of customized services from size, shape to surface treatment to ensure that the screws perfectly match your application scenarios.

5. Strict quality control: Following international quality standards, each batch of screws undergoes strict quality inspections to ensure the stability and reliability of product quality.

Application scenarios

●Heavy machinery and equipment: In large machinery that needs to withstand high torque and vibration, our brass screws provide stable connection support.

●Automobile manufacturing: Applied to key parts such as automobile chassis and engines to ensure safety and stability during vehicle driving.

●Marine engineering: In highly corrosive marine environments such as humidity and salt spray, brass screws show extraordinary corrosion resistance.

●Chemical equipment: In equipment exposed to chemical substances, its excellent chemical stability ensures long-term stable connection effects.

Technical parameters

●Material: High-quality brass (other alloy material options can be provided upon request)

●Strength grade: Meet or exceed industry standards, and provide a variety of strength grade options

●Surface treatment: Anti-corrosion coating (such as galvanizing, nickel plating), anodizing, etc., to enhance corrosion resistance and aesthetics

●Precision grade: High-precision processing to ensure consistency in size and shape

●Certification: Passed ISO, CE and other international certifications, in line with global quality standards

Service and support

●Quick response: Professional sales team and technical support team to ensure the efficiency of customer consultation and order processing.

●Customized service: Provide a full range of customized services from design to production to meet the personalized needs of customers.

●After-sales guarantee: A complete after-sales service system to solve any problems encountered by customers during use.

Conclusion

Choosing our industrial-grade custom brass screws means choosing a reliable, durable and efficient connection solution. We are committed to providing customers with the best quality products and services to help your project succeed. Contact us now to start your customization journey!