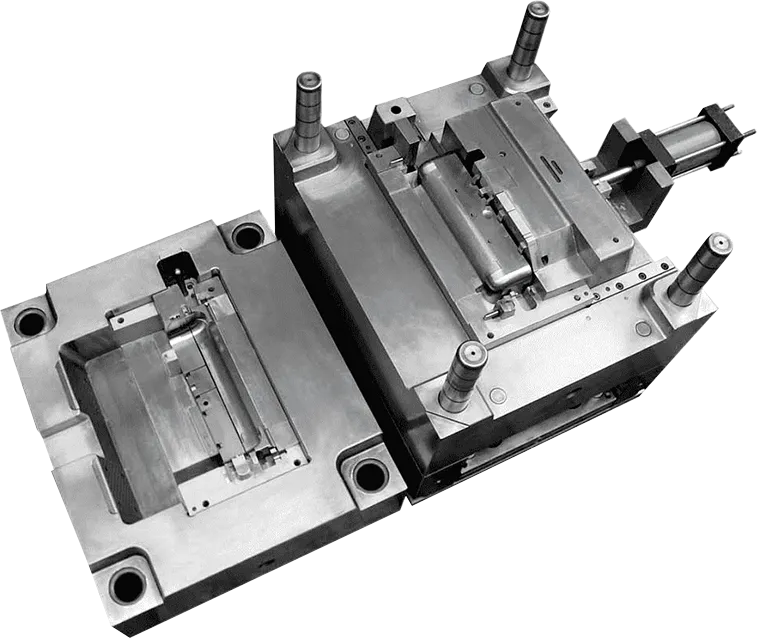

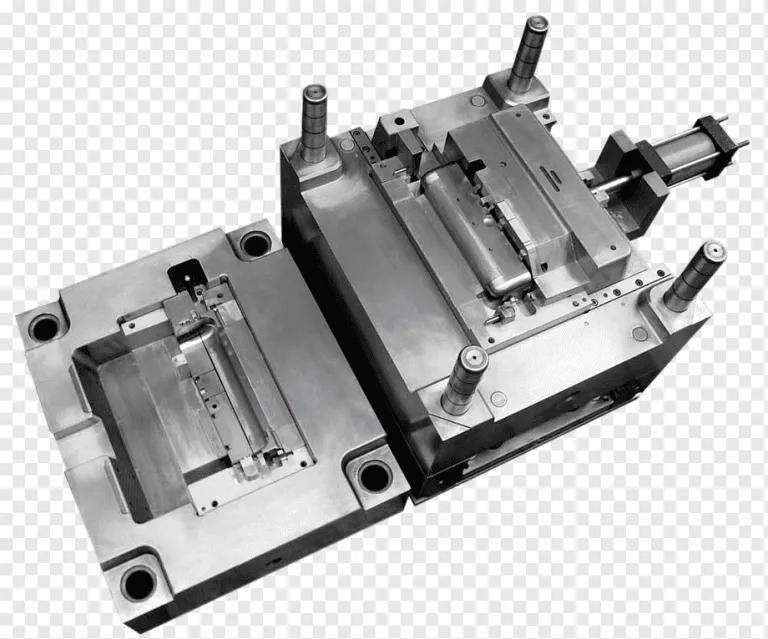

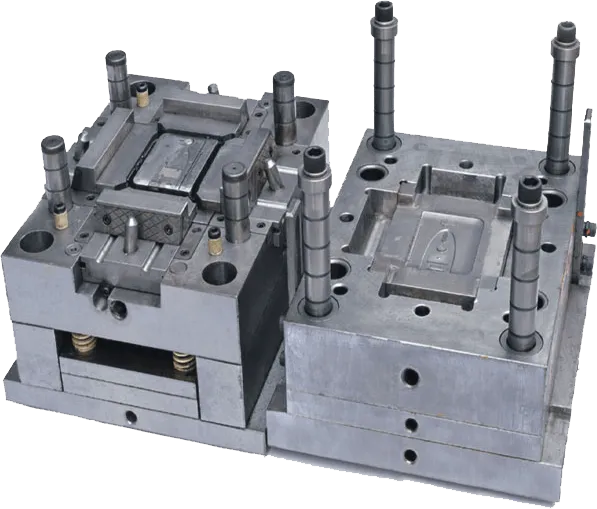

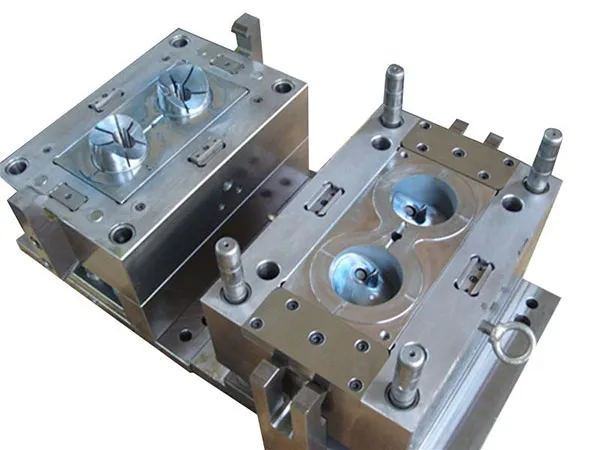

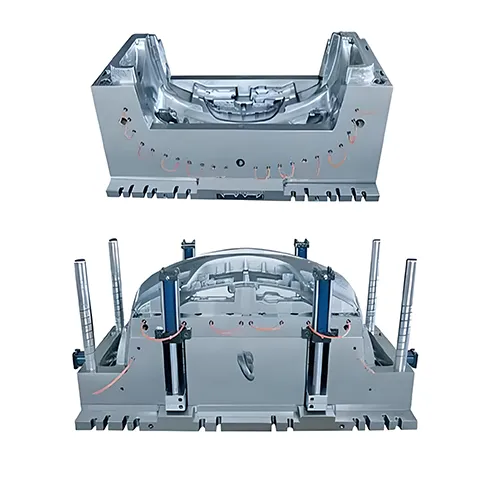

Customized wear-resistant PP injection mold for automotive parts

Place of Origin : XiaMen, China

Model : MJ-06

Keyword : Plastic Injection Molding Service and OEM Assembly

Discription : Custom Plastic Injection Molding Companies Supply Molded Parts

Mold Base : LKM, HASCO, DME or upon customer’s requirement

Mold Life : 50,000 to 1,000,000 shots & custom

Mold Core : 45#, 50#, P20, H13, 718, 1.2344, 1.2738, NAK80, S136 etc

Production Material : PP,PC,PS,PA6,POM,PE,PU,PVC,ABS,PMMA etc

Mold Cavity : Single or Multiply Cavities

Packaging : Polybag packing or packed according to customer requirement

Transportation : By sea or by air as customer requirement

Main Export Country : USA,UK,Germany,Switzerland,France,Italy,Austrialia and Southeast Asia

Description

product description

In today’s highly competitive market environment, the stability of a product’s structure directly determines its service life, safety and customer satisfaction. To this end, we have carefully developed high-strength injection molds, aiming to significantly improve the structural stability of the product through precise design and advanced manufacturing technology. This mold is designed for products that need to withstand high stress, high impact or extreme environmental conditions, such as automotive parts, electronic equipment housings, industrial machinery components, etc.

Features

1. High-strength material: Made of high-quality mold steel (such as P20, 718, NAK80, etc.), which undergoes precision processing and heat treatment to ensure that the mold has excellent strength and wear resistance and can withstand the huge impact force during high-pressure injection molding.

2. Precision design: Combined with advanced CAD/CAM technology and simulation analysis software, the mold structure is accurately designed and optimized to ensure the dimensional accuracy and shape stability of injection molded parts. At the same time, reasonable runner system and gate design can effectively reduce pressure and temperature fluctuations during the injection molding process and improve product quality.

3. Efficient production: The mold adopts a multi-cavity design, which can produce multiple products at one time, greatly improving production efficiency. At the same time, the optimized cooling system shortens the injection molding cycle and reduces production costs.

4. Structural stability: By optimizing the mold structure and injection molding process parameters, the shrinkage rate and deformation of the injection molded parts are effectively controlled to ensure that the product has excellent structural stability and dimensional consistency. This is essential to improve the overall performance and longevity of the product.

5. Wide applicability: This mold is suitable for a variety of plastic materials (such as ABS, PC, PA6, POM, etc.) and can meet the production needs of different industries and products. Whether it is in the automotive, electronics, medical or aerospace fields, you can find suitable application scenarios.

Application scenarios

●Auto parts: such as hoods, bumpers, door interior panels, etc., which require strong structures, impact resistance, and precise dimensions.

●Electronic device casing: such as mobile phone, tablet computer, laptop, etc. casings, which are required to be beautiful, lightweight and have high drop resistance.

●Industrial machinery components: such as gears, bearing seats, drive shafts, etc., need to withstand greater mechanical stress and wear.

●Medical equipment: such as surgical instruments, medical device casings, etc., which are required to be sterile, corrosion-resistant and structurally stable.

Technical Parameters

●Mold material: P20, 718, NAK80 and other high-quality mold steels

●Mold accuracy: ±0.01mm

●Mold life: 500,000-5 million injection molding times

●Injection molding materials: ABS, PC, PA6, POM and other plastic materials

●Production efficiency: multi-cavity design improves production efficiency

●Cooling system: Optimize the cooling system and shorten the injection molding cycle

Customized services

We provide a full range of customized services, including mold design, manufacturing, debugging and after-sales service. Customers only need to provide product drawings or samples, and we can customize the design according to specific needs to ensure that the mold fully meets production requirements. At the same time, we have a professional technical team and advanced production equipment to ensure the manufacturing quality and delivery time of the mold.

Summarize

High-strength injection molds, with their excellent performance and wide range of application scenarios, have become an important tool for improving product structural stability. We are committed to providing customers with high-quality mold products and high-quality customized services to help customers stand out in the fierce market competition. If you have any needs or questions about high-strength injection molds, please feel free to contact us and we will serve you wholeheartedly.