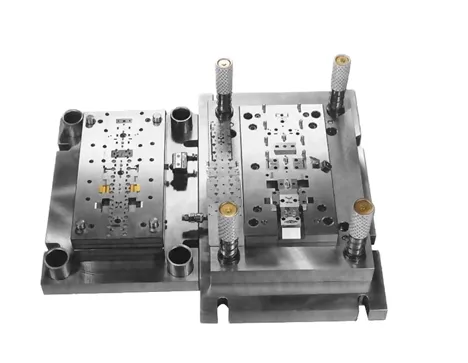

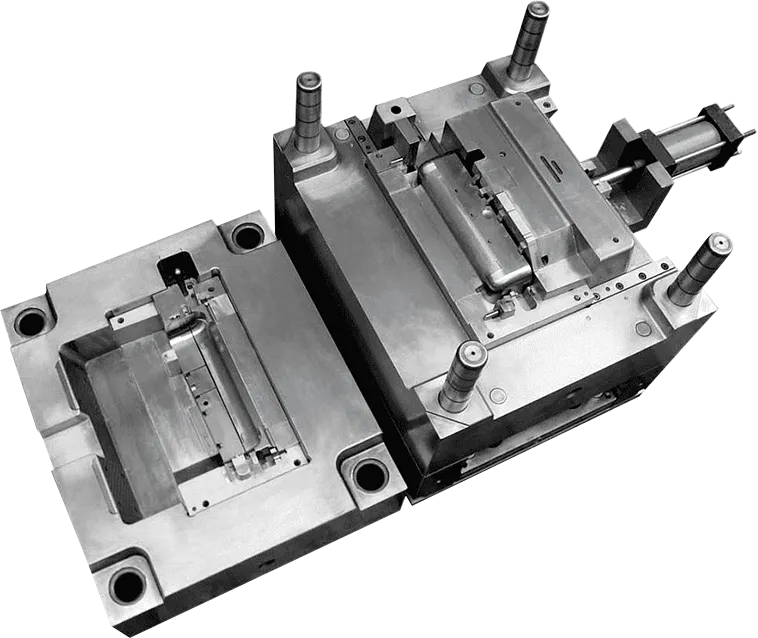

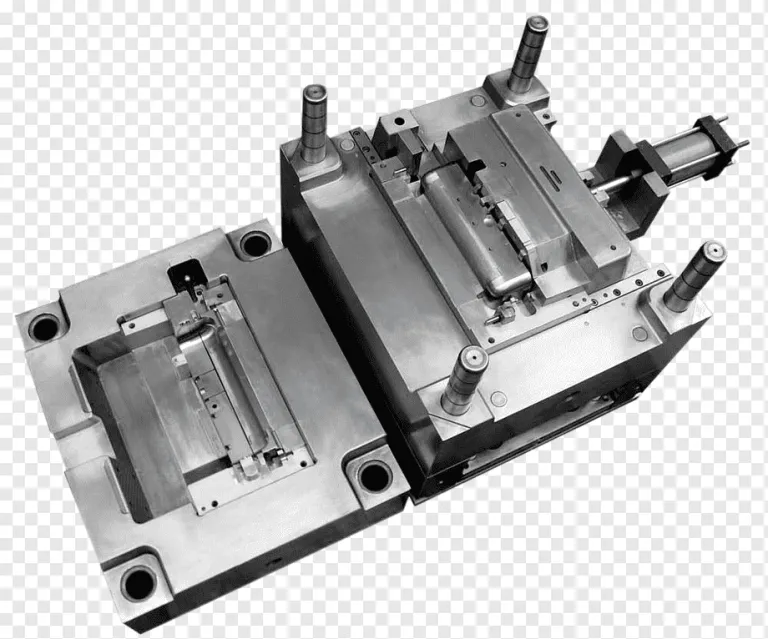

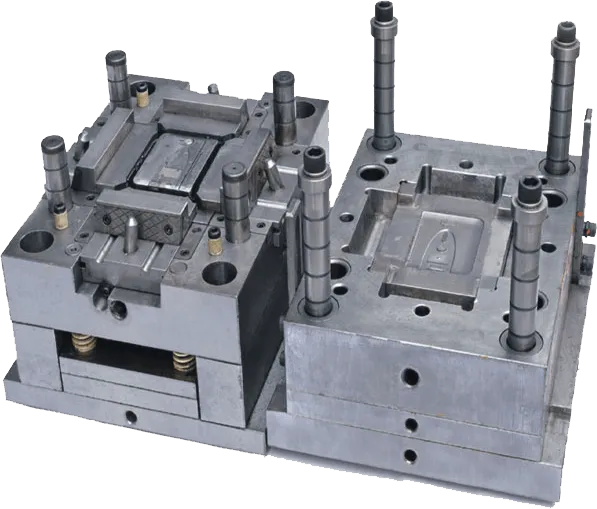

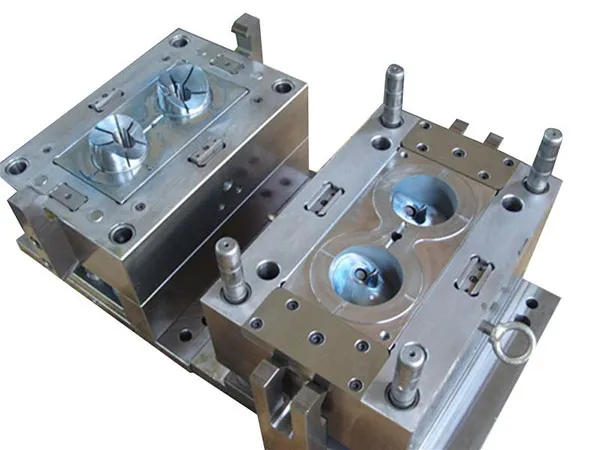

Customized electronic equipment anti-loosening design 5-axis precision injection mold

Place of Origin : XiaMen, China

Model : MJ-05

Keyword : Plastic Injection Molding Service and OEM Assembly

Discription : Custom Plastic Injection Molding Companies Supply Molded Parts

Mold Base : LKM, HASCO, DME or upon customer’s requirement

Mold Life : 50,000 to 1,000,000 shots & custom

Mold Core : 45#, 50#, P20, H13, 718, 1.2344, 1.2738, NAK80, S136 etc

Production Material : PP,PC,PS,PA6,POM,PE,PU,PVC,ABS,PMMA etc

Mold Cavity : Single or Multiply Cavities

Packaging : Polybag packing or packed according to customer requirement

Transportation : By sea or by air as customer requirement

Main Export Country : USA,UK,Germany,Switzerland,France,Italy,Austrialia and Southeast Asia

Description

Product Overview

In today’s manufacturing industry that pursues extreme precision and efficiency, our 5-axis precision injection molds provide a perfect solution for the production of precision parts with their excellent processing capabilities and unparalleled precision. By integrating advanced 5-axis CNC machining technology, we are able to create injection molds with complex structures and precise dimensions to meet the needs of various industries for high-quality precision parts.

Core Advantages

1. High-precision machining: Using 5-axis linkage machining technology to achieve precise engraving of complex surfaces, ensuring that every detail of the mold meets the design requirements, and the dimensional accuracy of the parts after molding is as high as ±0.01mm.

2. Efficient production: The optimized mold structure and efficient injection molding process can greatly shorten the production cycle, improve production efficiency and reduce production costs.

3. Material diversity: Supports injection molding of a variety of engineering plastics and special materials to meet the special requirements of different industries for material properties.

4. Strong durability: Select high-quality steel and undergo precision heat treatment process to ensure that the mold has high wear resistance, high hardness and long service life, reducing the frequency of mold replacement.

5. Customized service: Provide one-stop customized service from product design, mold development to injection molding production to meet customers’ personalized needs.

Technical features

●High-precision CNC machining center: Equipped with internationally advanced 5-axis CNC machining center to ensure machining accuracy and stability.

●3D modeling and simulation technology: Use CAD/CAM software for mold 3D modeling and injection molding simulation analysis to discover and solve problems in advance and reduce mold trial costs.

●Precision measurement and testing: Use high-precision measuring instruments to conduct all-round testing of molds and parts to ensure product quality.

Application scenarios

●Electronic products: Precision parts such as mobile phone housings and tablet computer frames.

●Automotive industry: Automotive parts such as engine covers, dashboards and other high-precision injection molded parts.

●Medical devices: Precision medical device housings and internal components.

●Aerospace: High-precision aviation components and structural parts.

Quality assurance

We strictly follow the ISO quality management system standards, and every link from raw material procurement, production and processing to finished product inspection is strictly controlled. At the same time, we provide perfect after-sales service to ensure that any problems encountered by customers during use can be solved in a timely manner.

Customer Value

Choosing our 5-axis precision injection mold, you will get high-quality and efficient precision parts production solutions, improve product competitiveness, reduce production costs, and achieve sustainable development of the enterprise.