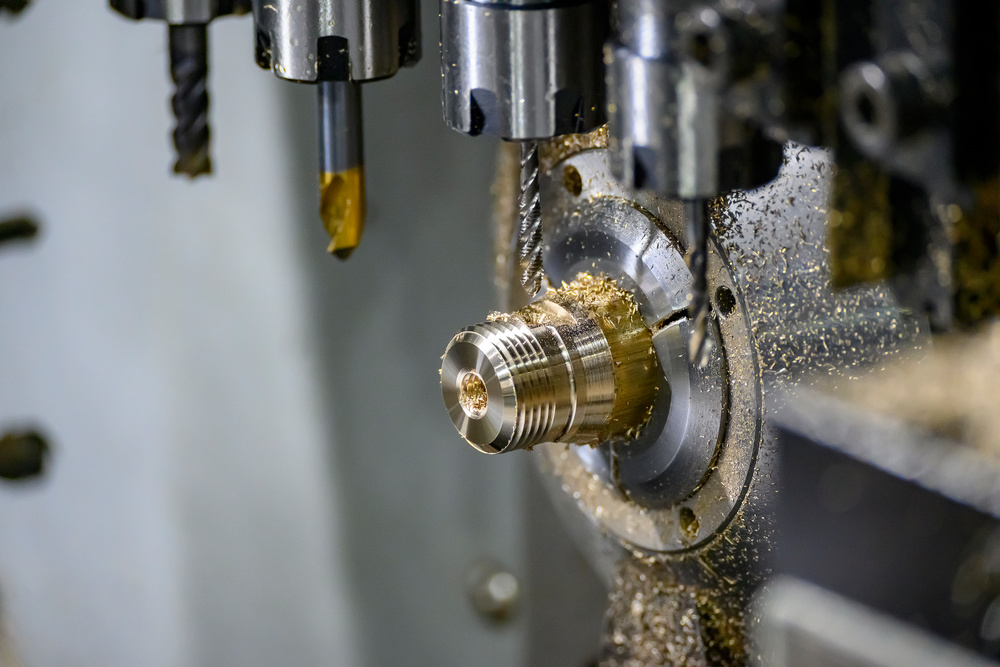

Custom wear-resistant precision instrument brass threaded parts

Place of Origin : Xiamen,China

Name : CNC Brass Threaded Fittings

Model : CNC-24

Material : Brass/steel/stainless steel/aluminum alloy etc.

Application : Connectors/Fasteners

Size : Customized

Shape : Customized

Application : As per customer’s request

Surface treatment : According to customer’s requirement

Processing Technology : CNC Processing such as Turning / Milling

Certification : ISO9001

Description

Product Specs (The Good Stuff)

Material Options

H59 Brass, HPb59-1, C36000 – bro, we got all the good brass alloys!

Tolerance

Up to ±0.01mm – that’s like, super tight! Your parts will fit better than a puzzle piece.

Thread Types

UNC, UNF, Metric, BSP – whatever thread you need, we got you covered!

Lead Time

3-10 days depending on quantity – we don’t mess around with slow delivery!

How We Make These Bad Boys

CNC Turning Process

Okay, so here’s the deal: we spin the brass at high speeds (like, really fast) and use cutting tools to shape it into cylindrical parts. It’s like a pottery wheel but for metal, and way more precise!

For brass, we can run at 2000+ RPM – that’s quick enough to make your head spin! The chips just fly off, leaving a super smooth surface.

Threading Process

This is where we get fancy with the threads. We use specialized threading tools that cut perfect spiral grooves – no more hand-tapping garbage!

Our CNC machines can create any thread pattern you need – from fine micro-threads to heavy-duty industrial threads. It’s like magic, but with metal!

Material Deep Dive (Nerd Alert)

H59 Brass

Pros: Cheap, good machinability, decent strength – perfect for most projects!

Cons: Not the strongest, but who needs that for most stuff?

Tensile Strength: 390 MPa (test data, for reference only)

HPb59-1 Brass

Pros: Excellent machinability, good corrosion resistance – the workhorse!

Cons: Contains lead, so not for food contact

Corrosion Life: >5000 hours (test data, for reference only)

C36000 Brass

Pros: Free-cutting, super smooth finish – perfect for precision parts!

Cons: More expensive, but worth it for quality

Hardness: 120-160 HB (test data, for reference only)

We Don’t Mess Around With Quality

ISO 9001:2015

Quality management system certified – we know what we’re doing!

FDA Approved

Food grade certified for lead-free brass – safe for drinking water!

RoHS Compliant

Environmentally friendly – no harmful chemicals here!

Testing & Inspection (The Proof)

Salt Spray Test: 240 hours no red rust, 480 hours ≤5% corrosion area (test data for reference only)

Thread Gauge Testing: Every thread is checked with precision gauges – no sloppy threads here!

Dimensional Inspection: CMM checks every dimension with 0.001mm accuracy – perfect every time!

Material Certification: Every batch comes with a certificate – no mystery metals here, bro!

Where You Can Use These Parts

Plumbing

Fittings, valves, connectors – your pipes will love these upgrades!

Electronics

Connectors, terminals, heat sinks – your gadgets will run smoother!

Marine

Boat fittings, hardware – corrosion-resistant for saltwater!

Industrial

Machinery parts, valves, pumps – built to last in tough environments!

FAQs (You’re Welcome)

How much do these parts cost?

Depends on material, complexity, and quantity – hit us up for a quote, we won’t break the bank!

Can you make custom thread sizes?

Absolutely! Send us your specs and we’ll make whatever thread you need – no job is too weird!

What’s the minimum order quantity?

No minimum! We’ll make 1 part or 10,000 parts – whatever you need, bro.

Do you offer surface treatments?

Heck yeah! Plating, coating, polishing – we can make your parts look as good as they perform.

Ready to Get Your Brass Parts Made?

Contact us today for a free quote – your project deserves the best!