Custom Ball Head Screw Bolts | High Strength Alloy Steel / Stainless

Place of Origin : XiaMen, China

Model : CNC-23

Color : Yellow,Sliver

MOQ : 1pcs

Packing : Plastic Bag+carton+pallet

Delivery time : 7-25 Working Days

Service : OEM\ODM

Sample : Available

Quality : 100% Qualified

Logo : Accept Customized Logo

Material : Stainless Steel

Description

Custom Load-Bearing Ball Head Screw Bolts – Alloy Steel / Stainless Steel

Solve loose or corroded fasteners in heavy-duty applications with our custom ball head / eye bolts.

• High tensile strength ≥1000 MPa (alloy steel) or marine-grade 316 SS

• Adjustable articulation for misalignment compensation

• Precision CNC ±0.01mm – no galling, easy assembly

• Load capacity customizable up to 40 kN (4 tons)

• Ideal for automation arms, machinery linkages, medical devices, aerospace fixtures

Product Overview

Our custom ball head bolts are precision-engineered fasteners designed to provide superior articulation and load-bearing capabilities in demanding applications. Unlike standard fasteners, these specialized components allow for controlled movement while maintaining structural integrity, making them ideal for dynamic systems where misalignment compensation is critical.

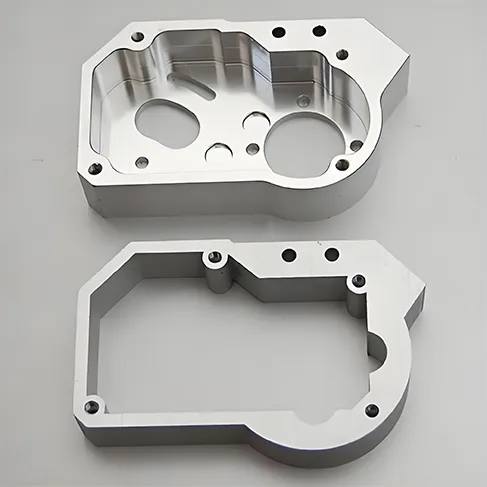

Each bolt is manufactured using state-of-the-art CNC machining centers to ensure exacting tolerances and consistent performance. We offer complete customization to meet your specific design requirements, from material selection to geometric configuration.

Core Technical Advantages

Precision Machining

CNC Swiss-type turning with ±0.01mm tolerance on critical dimensions

Articulation Design

Engineered for smooth movement and misalignment compensation

Material Expertise

Specialized alloys with optimized mechanical properties

Corrosion Resistance

Advanced surface treatments for harsh environments

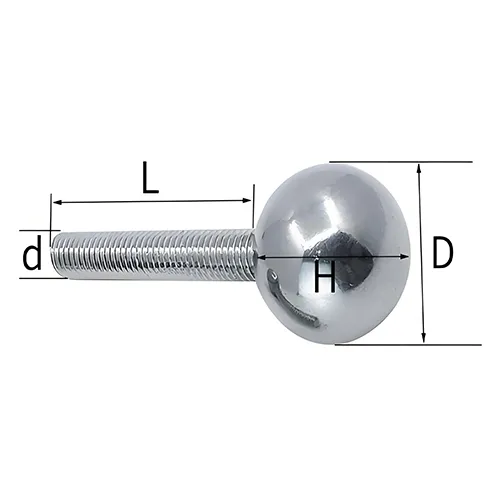

Technical Specifications

| Parameter | Details | Value | Test Standard |

|---|---|---|---|

| Thread Size | Metric/UNC/UNF | M6-M30 / #10-1″ | ISO 898-1 |

| Ball Diameter | Standard Sizes | 10-50mm | Custom |

| Length Range | Total Length | 20-300mm | DIN 933 |

| Swing Angle | Articulation Range | ±15-30° | Custom |

| Tolerance | Critical Dimensions | ±0.01mm | ISO 2768 |

| Load Capacity | Working Load Limit | Up to 40 kN (4 tons) | ASME B30.26 |

| Fatigue Life | Cycle Count | ≥10^6 cycles | ASTM E466 |

Material Comparison

| Property | Alloy Steel (40Cr/42CrMo) | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|---|

| Tensile Strength | ≥1000-1400 MPa | ≥520 MPa | ≥550 MPa |

| Hardness (HRC) | 28-36 | 18-22 | 18-24 |

| Corrosion Resistance | Good (with coating) | Excellent | Superior (marine grade) |

| Salt Spray Test | 24-48 hours | 168 hours | 500+ hours |

| Temperature Resistance | Up to 500°C | Up to 800°C | Up to 870°C |

| Price Relative | Lowest | Medium | Highest |

| Best For | High load, high strength applications | General industrial use | Marine, chemical, food industries |

Why Choose Our Custom Ball Head Bolts?

vs Standard Fasteners

- Custom Articulation: Solves misalignment issues in dynamic applications

- Longer Life: Superior fatigue resistance in vibration/heavy load environments

- Precision Fit: CNC machining ensures perfect fit for your specific design

- Material Selection: Choose the optimal material for your application

- Performance Optimization: Tailored to your exact load and movement requirements

Our Competitive Advantages

- DFM Expertise: Design for manufacturability optimization

- Small MOQ: Sample orders from 1 piece available

- Fast Turnaround: 24h quote, 7-15 days sample delivery

- Full Traceability: Material certificates and inspection reports

- Engineering Support: Technical assistance throughout the design process

Real-World Applications

Used in European automation lines – reduced downtime by 40% compared to standard fasteners

Detailed Application Areas

Industrial Robotics

- • Robotic arm joints and linkages

- • End-effector attachments

- • Gripper mechanisms

- • Collaborative robot safety systems

- • Precision positioning systems

Enables smooth movement and precise positioning in high-cycle applications

Automation Equipment

- • Conveyor systems and linkages

- • Assembly line mechanisms

- • Indexing tables and rotary stages

- • Pick-and-place machines

- • Packaging machinery

Compensates for manufacturing tolerances and thermal expansion

Medical Devices

- • Imaging equipment fixtures

- • Surgical instrument articulation

- • Patient positioning systems

- • Diagnostic equipment mounts

- • Rehabilitation devices

Provides precise, smooth movement in critical medical applications

Aerospace & Defense

- • Ground support equipment

- • Test fixture articulation

- • Avionics mounting systems

- • Weapon system components

- • Satellite deployment mechanisms

Meets stringent performance and reliability requirements

Customization Process

Upload Drawing

Submit your CAD file or technical drawing

DFM Analysis

24h design for manufacturability review

Quote & Approval

Receive detailed quotation and lead time

Production

Precision manufacturing and quality control

Delivery

Fast shipping with full documentation

Quality Assurance

IATF 16949 / ISO 9001 Certified

Our manufacturing facilities are certified to international quality standards, ensuring consistent performance and reliability.

Material Certifications

Full traceability with EN10204 3.1 material certificates and RoHS/REACH compliance documentation.

Global Export Experience

Export to US/EU/JP since 2015 with proven track record of meeting international standards and customer requirements.

Customer Feedback

“The custom ball head bolts we received have been performing flawlessly in our robotic end-effectors. The precision machining and material quality exceed our expectations. We’ve seen a 40% reduction in downtime compared to our previous suppliers.”

– European Automation Systems Integrator

Technical Documentation & Support

Comprehensive Technical Support

- 📐

Design Assistance: Our engineering team can help optimize your ball head bolt design for manufacturability and performance

- 📊

Performance Data: Complete material test reports, load capacity charts, and fatigue analysis available upon request

- 📄

Documentation Package: Includes CAD files, material certificates, inspection reports, and installation guidelines

- 🔧

Installation Support: Technical guidance for proper installation and maintenance procedures

Available Documentation

📁

Material Certificates

EN10204 3.1, Mill Test Reports

📁

Test Reports

Tensile, Hardness, Fatigue Testing

📁

CAD Files

STEP, IGES, SolidWorks, AutoCAD

📁

Installation Guide

Torque specifications, maintenance procedures

📁

Compliance Documents

RoHS, REACH, FDA, NSF certifications