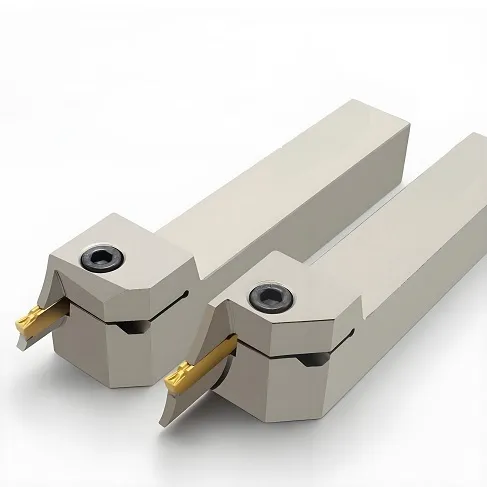

Customized high precision CNC turning tools

Place of Origin : XiaMen,China

Warranty : 6months

Customized support : OEM

Brand Name : JSD

Model Number : CNC-02

Products name : CNC Turning Tools

Application : Lathe Tool Holding Accessories

MOQ : 1 Piece

Advantage : High Quantity Made

Packing : Custom

Delivery : 10-15days

Description

Product Description:

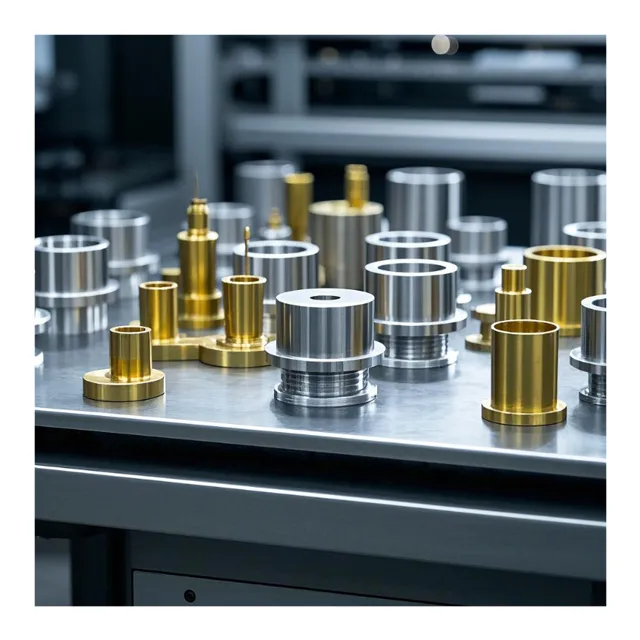

CNC precision turning tool set, built with high quality materials, designed for high precision machining needs. This product is suitable for all kinds of metal, non-metallic materials precision machining, widely used in aerospace, automotive manufacturing, mold processing and other fields. It makes your processing more efficient and accurate, and comprehensively improves the quality of your products.

Product Features:

1. High-quality materials: choose high-quality cemented carbide, high-speed steel and other materials, with high hardness, high wear resistance, high corrosion resistance, to ensure machining accuracy and service life.

2. Precision design: Adopt unique blade shape and edge processing technology, reduce cutting resistance, reduce wear and improve machining efficiency.

3. Excellent cutting performance: suitable for machining various complex curved surfaces and shaped parts, realizing high-precision, high-finish and high-efficiency machining effect.

4. Diversified choices: provide a variety of models and specifications of cutting tools to meet different machining needs and workpiece sizes.

5. Stable and reliable: Strict production process and quality control ensure that each product can operate stably and reduce the failure rate.

6. Easy to operate: humanized design facilitates quick tool change and improves work efficiency.

Product Parameters:

● Material: cemented carbide, high-speed steel

● Tool type: external turning tool, internal hole turning tool, end face turning tool, thread turning tool, etc.

● Scope of application: metal, non-metallic materials

● Processing accuracy: 0.005mm (can be customized according to demand)

Purchase Suggestion:

● According to the workpiece material, machining requirements and machine tool models to choose the appropriate tool type and specifications.

● When purchasing, please make sure the product packaging is intact, if damaged, please contact us in time.

● Before use, please read the product manual in detail to understand the tool performance and precautions.

● Regularly maintain the tool to ensure the machining effect and service life.