In the world of industrial manufacturing, where consistency, speed, and accuracy define success, a professional metal stamping kit isn’t just equipment—it’s a strategic asset. Unlike basic hobby kits, professional systems are engineered to handle high-volume production, tight tolerances, and diverse materials, making them indispensable for industries from automotive to aerospace. At Goldcattle, with 26+ years of precision fabrication expertise, we design professional stamping kits that combine robust machinery, custom tooling, and smart workflows to deliver reliable results, every time. Let’s dive into what makes a professional metal stamping kit essential, its key components, and why Goldcattle’s solutions stand out in industrial settings.

What Defines a Professional Metal Stamping Kit?

A professional metal stamping kit is a integrated system built for industrial-grade performance, designed to produce consistent, high-quality parts at scale. Unlike entry-level kits, it prioritizes:

- Heavy-duty construction to withstand continuous operation.

- Precision engineering for tight tolerances (often ±0.01mm or better).

- Material versatility to handle metals from thin aluminum to thick steel.

- Safety and compliance with global industrial standards (OSHA, CE, ISO).

These kits bridge the gap between prototype development and mass production, ensuring that even complex parts—like automotive brackets or electronics enclosures—are manufactured with repeatable accuracy.

Core Components of a Professional Stamping Kit

A professional kit is more than a press and die; it’s a ecosystem of tools working in sync. Here’s what sets industrial-grade systems apart:

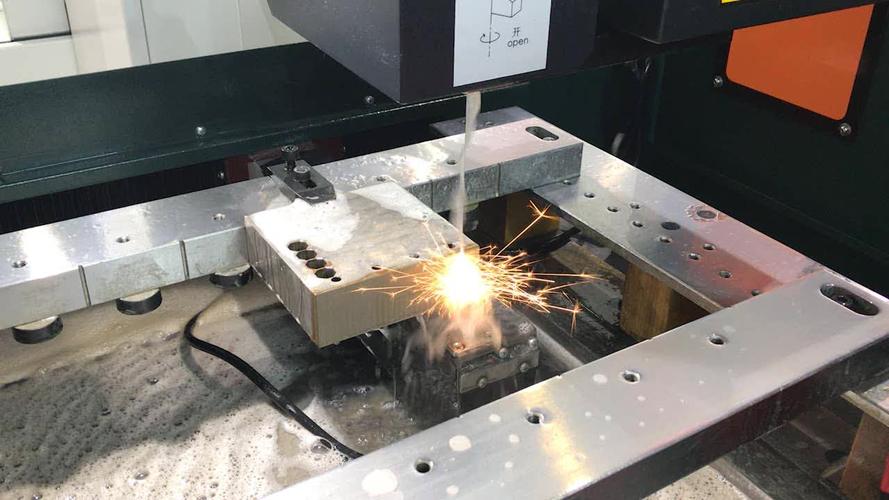

1. Industrial-Grade Stamping Presses

The press is the workhorse, delivering controlled force to shape metal. Professional kits offer presses tailored to production demands:

- Mechanical presses: Ideal for high-speed production (50–300 parts per minute) with precise stroke control, perfect for small to medium parts like washers or terminals .

- Hydraulic presses: Provide adjustable force (50–1,000 tons) and slower, more controlled movement, suited for thick materials (3–15mm steel) or deep drawing applications like tank ends .

- Servo presses: Combine speed (up to 200 SPM) with energy efficiency, offering programmable force profiles for complex parts requiring variable pressure.

Goldcattle’s 100-ton servo press recently helped an automotive client produce 100,000 steel suspension brackets monthly with ±0.02mm dimensional accuracy, reducing scrap rates by 28% compared to their old hydraulic press.

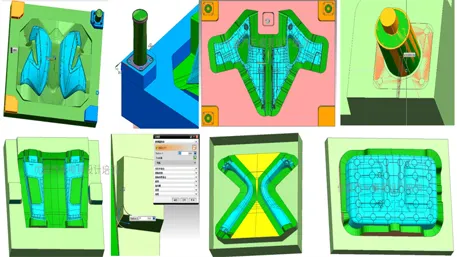

2. Custom Precision Dies

Professional kits rely on high-performance dies that translate design into reality:

- Tool steel construction: Made from H13 or D2 steel (58–62 HRC hardness) for durability, withstanding 500,000+ cycles for steel parts .

- Advanced machining: CNC-machined on 5-axis centers with ±0.002mm accuracy, capturing intricate features like micro-grooves or threaded inserts.

- Progressive and transfer dies: For complex parts, these integrate multiple operations (blanking, bending, piercing) in one cycle, cutting production time by 40–60% .

For a medical device client, Goldcattle’s progressive die stamped 0.5mm-thick stainless steel surgical tool components with 0.1mm-wide slots, achieving 99.9% dimensional consistency across 50,000 parts.

3. Automated Material Handling & Integration

Professional kits minimize human error with automated systems:

- Coil feeders: Unwind, straighten, and feed metal coils (up to 1,000kg) at consistent speeds, ensuring uniform material flow.

- Robotic part removal: 6-axis robots extract finished parts, reducing cycle time by 15–20% and preventing operator fatigue .

- Inline inspection: Vision systems check critical dimensions in real time, rejecting out-of-tolerance parts before they reach downstream processes.

Goldcattle integrated a robotic feeder into a client’s kit, increasing their daily output of brass electrical connectors from 8,000 to 12,000 parts with zero manual handling.

4. Safety & Ergonomic Features

Industrial environments demand rigorous safety:

- Light curtains and area scanners: Stop presses instantly if operators enter danger zones.

- Ergonomic workstations: Adjustable height controls and anti-fatigue mats reduce operator strain during long shifts.

- Noise reduction enclosures: Lower decibel levels to <85dB, complying with OSHA noise regulations .

Our safety-certified kits helped a client’s facility achieve 365 days without lost-time accidents, a first in their 10-year history.

Key Benefits of Professional Stamping Kits in Industry

1. Unmatched Production Efficiency

Professional kits maximize throughput with:

- Fast cycle times (10–300 parts per minute, depending on part size).

- Minimal setup time (quick-change dies reduce changeover to 15–30 minutes).

- Low scrap rates (typically <1% for optimized processes) .

A consumer electronics manufacturer using Goldcattle’s kit increased monthly production of aluminum chassis parts from 50,000 to 200,000, meeting seasonal demand without adding shifts.

2. Precision for Critical Applications

Industries like aerospace and medical require parts that perform under extreme conditions. Professional kits deliver:

- Tight tolerances (±0.005–0.01mm) for seamless part integration.

- Consistent surface finishes (Ra 0.8–3.2μm) to prevent friction or corrosion.

- Repeatable mechanical properties (e.g., hardness, tensile strength) through controlled forming.

Goldcattle’s kit produced titanium aerospace brackets with ±0.008mm hole alignment, ensuring they passed rigorous vibration testing (10–2,000Hz) without failure.

3. Cost Savings at Scale

While professional kits require higher initial investment, they reduce long-term costs:

- Lower per-unit costs due to high throughput and minimal scrap.

- Extended die life (500,000+ cycles) reduces tooling replacement expenses.

- Energy-efficient servo presses cut electricity costs by 20–30% compared to older hydraulic models .

A HVAC manufacturer saved $150,000 annually after switching to Goldcattle’s kit, thanks to reduced energy use and scrap rates.

Why Goldcattle’s Professional Stamping Kits Lead the Industry

- Custom Engineering: We design kits around your parts, materials, and production goals. For example, we built a specialized kit for a battery manufacturer that integrates stamping with ultrasonic welding, eliminating a secondary process.

- Global Compliance: Kits meet ISO 9001, IATF 16949 (automotive), and ISO 13485 (medical) standards, ensuring regulatory approval for critical industries.

- Lifetime Support: From installation to maintenance, our engineers provide training, troubleshooting, and die reconditioning, extending kit lifespan by 30% on average.

- Smart Integration: Our kits connect with MES systems for real-time production tracking, helping clients optimize workflows and reduce downtime.

FAQs About Professional Metal Stamping Kits

Q: What materials can a professional stamping kit handle?

A: They process everything from thin gauge aluminum (0.2mm) and brass to thick carbon steel (15mm) and stainless steel (10mm), with options for exotic metals like titanium or copper alloys .

Q: How long does it take to set up a professional kit?

A: Installation and commissioning take 2–4 weeks, with full production readiness achieved within 1–2 months, including operator training.

Q: Can professional kits handle low-volume production?

A: Yes! Quick-change dies and flexible programming make them suitable for batch sizes as small as 1,000 parts, balancing precision with flexibility.

Q: What maintenance do professional kits require?

A: Routine maintenance includes daily lubrication checks, weekly die inspection, and monthly press calibration—tasks our team can train your staff to perform or handle via service contracts.

Q: How do I know which press size is right for my parts?

A: Goldcattle’s engineers calculate required tonnage based on material type, thickness, and part complexity. For example, a 3mm steel bracket with a 50mm bend requires ~30 tons of force.

Ready to Upgrade Your Stamping Capabilities?

A professional metal stamping kit isn’t just equipment—it’s a partner in scaling your production, ensuring quality, and reducing costs. At Goldcattle, we combine industrial expertise with custom engineering to deliver kits that meet your unique needs, whether you’re producing 1,000 or 1,000,000 parts monthly.

Visit https://www.xmgoldcattle.com/ to schedule a consultation or request a free production analysis. Let’s build a kit that powers your manufacturing success.

Have a specific part or production challenge? Share your details below—our stamping experts will design a tailored solution for you!