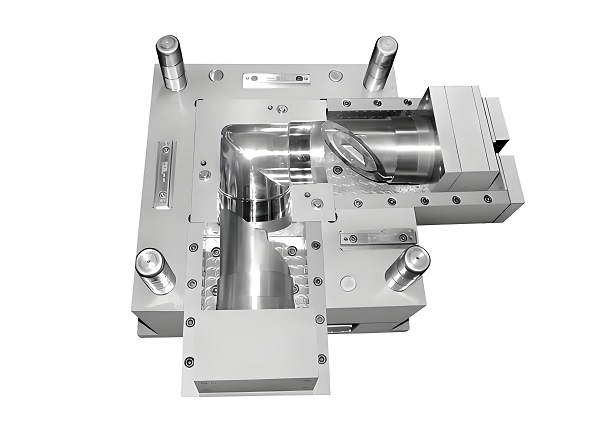

PVC pipe fitting molds, as the core tool for plastic products production, its design and manufacturing quality directly determine the molding effect, production efficiency and service life of PVC pipe fittings (such as water pipes, drainage pipes, electric wire pipes, etc.). The purpose of this manual is to introduce the customized service of PVC pipe fitting molds in detail, covering process, materials, characteristics, application areas, product data testing and service advantages, etc., in order to meet the customer’s customized demand for high-quality molds.

1. Material and process

Main material: High quality alloy steel or stainless steel is used to ensure the high strength, high hardness and good wear resistance of the mold.

Heat treatment process: After precise heat treatment, to improve the hardness and deformation resistance of the mold, to extend the service life.

Precision machining: CNC numerical control machining center is used to ensure the accuracy and dimensional stability of the mold.

Surface treatment: Electroplating, nitriding or sandblasting treatment is optional to enhance the corrosion resistance and surface finish of the mold.

2. Product Characteristics

High precision: accurate mold design ensures that the dimensions of PVC pipe fittings produced are precise and meet the standards.

High efficiency: Optimize the structure of the mold to improve the production speed and reduce the production cycle.

Long service life: Adopting high quality materials and precision technology, the mold has a long service life and reduces the production cost.

Easy maintenance: the mold design is easy to disassemble and clean, reducing maintenance cost.

3. Application areas

Construction industry: used to make water pipes, drainage pipes, electric wire pipes, etc.

Agricultural irrigation: to make pipe fittings for agricultural irrigation systems.

Chemical industry: used to make corrosion-resistant chemical pipes and pipe fittings.

Municipal engineering: used in urban water supply and drainage systems, gas pipelines, etc.

4. Product data testing

Hardness test: detecting the hardness of the mold material to ensure that it meets the production requirements.

Accuracy test: use CMM to detect the dimensional accuracy of the mold to ensure the product meets the design requirements.

Abrasion resistance test: simulate the actual production conditions, test the abrasion resistance of the mold and predict the service life.

Corrosion resistance test: For surface treated molds, corrosion resistance test is conducted to ensure that the molds can still maintain good performance in wet or corrosive environments.

5. Service Advantages

Personalized customization: according to customer needs, provide a full range of customized services from mold design, material selection to special features (such as high temperature resistance, corrosion resistance).

Rapid response: establish a rapid response mechanism to ensure that customer inquiries, orders, after-sales and other issues are handled in a timely manner.

Technical support: Provide detailed mold manuals, installation guides and operation videos, support on-site installation guidance and technical training.

Continuous optimization: Collect customer feedback regularly, continuously optimize the mold design and production process, and improve product quality and service level.

6.Customization Process

Demand communication: Customers submit customized demands by phone or online platform, including mold type, size, material, production quantity, special requirements, etc.

Program design: the technical team according to customer demand, design preliminary program, including mold structure design, material selection, production process, etc..

Solution Confirmation: The customer reviews and confirms the design, and discusses details such as price and delivery date.

Mould Manufacturing: Manufacture the mold according to the confirmed plan, including material procurement, processing, heat treatment, surface treatment, etc.

Quality Inspection: After completing all the manufacturing process, strict pre-factory quality inspection is carried out to ensure the quality of the mold.

Shipment and after-sales service: After ensuring that the mold meets the standard, arrange for shipment and provide comprehensive after-sales service support.

Conclusion

PVC Pipe Fitting Mould Customized Service Manual is designed to provide customers with detailed product information and customized service guide, to ensure that every customer can get the most suitable mould products for their production needs. We promise to help you improve your production efficiency and product quality with high quality products, professional service and continuous innovation. We look forward to working with you to create the future!