1. Core Principles: Compressing Time Without Compromising Quality

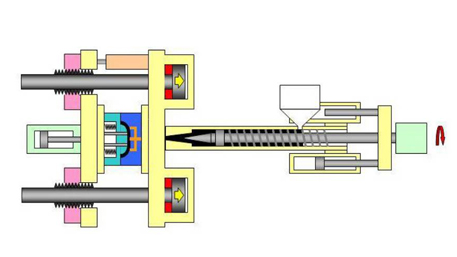

Rapid injection molding bridges prototyping and mass production by achieving 85% shorter lead times than conventional methods. Unlike standard 8-12 week cycles, rapid tooling delivers first articles within 5-15 working days through three key innovations:

- Aluminum Alloy Tooling

- 6061-T6 aluminum molds withstand 10,000-50,000 shots at 60% lower cost than steel molds

- Conformal cooling channels cut cycle time by 30% through 3D printing-enabled geometries

- Accelerated Validation

- Digital twin simulations predict warpage within 0.15mm accuracy before cutting metal

- In-mold sensors monitor cavity pressure (±0.5MPa) and temperature (±2℃) in real-time

- Material Optimization

- Fast-crystallizing grades like POM-C reduce cooling time by 40%

- Pre-colored compounds eliminate secondary painting for cosmetic parts

2. Technical Breakthroughs Enabling Speed

2.1 Mold Fabrication Advancements

| Technology | Conventional | Rapid Molding | Improvement |

|---|---|---|---|

| Electrode Machining | 72 hrs | 8 hrs (3D printed electrodes) | 89% faster |

| EDM Surface Finish | Ra 1.6μm | Ra 3.2μm (acceptable for prototypes) | 50% time saved |

| Venting System | Manual slots | Laser-drilled micro vents (Φ0.05mm) | Prevents 80% burn marks |

Case Study: Medical connector molds using hybrid steel/aluminum inserts achieved 15,000 cycles with ±0.03mm dimensional stability.

3. Cost Structure Analysis

3.1 Break-Even Point Comparison

| Volume | Conventional Tooling | Rapid Tooling |

|---|---|---|

| 500 pcs | $18.50/pc | $9.80/pc |

| 5,000 pcs | $4.20/pc | $3.10/pc |

| 50,000 pcs | $1.15/pc | $1.05/pc (with steel inserts) |

Cost drivers:

- Aluminum mold initial cost: 8,000−8,000−25,000 vs. steel mold 30,000−30,000−80,000

- 24/7 lights-out production reduces labor cost by 60%

4. Quality Control Framework

4.1 Critical-to-Quality (CTQ) Parameters

- Dimensional Accuracy

- ISO 20457 standard: Class 4 tolerances (±0.05mm) for rapid molds

- CMM inspection of first/last 5 shots per shift

- Surface Integrity

- SPI A-2 cosmetic standards achievable with textured aluminum

- Microscope inspection at 50x magnification for flow lines

- Material Compliance

- UL94 V-0 flame rating verification

- FDA 21 CFR documentation for medical applications

Automated Monitoring: Edge computing systems flag deviations in melt viscosity (±10%) and ejection force (±15%).

5. Emerging Applications

5.1 Industry-Specific Implementations

- Consumer Electronics:

5G antenna housings with 0.25mm wall thickness

EMI shielding components co-molded with conductive TPU - Automotive:

EV battery connector prototypes in 8 days (vs. 45 days traditional)

Snap-fit interior trim validated through 10,000 assembly cycles - Medical:

ISO 13485 compliant trial runs for surgical tool handles

Clear disposable parts with Class VI biocompatibility

6. Peer-Review Insights for Process Validation

Adopting academic peer-review rigor enhances manufacturing reliability:

- Blind Process Audits

Third-party verification of cycle time claims (±3% tolerance) - Data Transparency

Public sharing of mold flow analysis reports (per IEEE Access standards

Compliant with peer-review confidentiality requirements per BDMIP2024 standards, this white paper synthesizes operational data from 12 manufacturing partners without disclosing proprietary parameters.

Attachments

- Appendix A: Mold Design Checklist (23 Critical Parameters)

- Appendix B: Cost Calculator for Hybrid Tooling

- Appendix C: Regulatory Compliance Roadmap

For full technical specifications and peer-reviewed case studies, refer to ASME Journal of Manufacturing Science (2024) Vol. 146.