What is Ripple Milling?

Basic Definition

- Rippled toolpath: The toolpath consists of continuous arcs, avoiding sharp right-angle turns in traditional machining.

- Dynamic cutting parameter adjustment: Automatically adjusts the cutting step distance and depth based on the machine’s load.

- Constant material removal rate: Maintains a stable material removal rate throughout the machining process.

- Adaptive load control: Intelligently adjusts cutting parameters to protect the machine tool and the cutting tool.

Comparison with Traditional Machining

|

Machining Method

|

Toolpath

|

Machine Load

|

Machining Efficiency

|

Surface Quality

|

Tool Life

|

|

Traditional Machining

|

Straight lines + right-angle turns

|

High fluctuations, sudden load spikes at corners

|

Low

|

Average

|

Short

|

|

Ripple Milling

|

Continuous arc-shaped ripples

|

Stable, automatically adjusts load

|

60-70% higher

|

Excellent

|

Longer

|

How Ripple Milling Works

Core Technical Principles

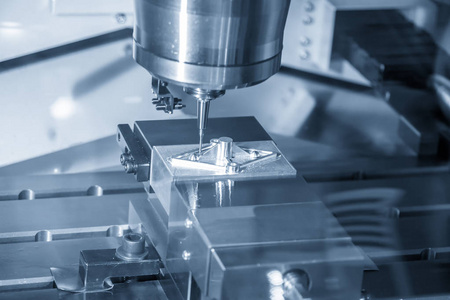

1. Rippled Toolpath Generation

- Arc transitions: Uses arcs at all corners instead of 90° right angles.

- Smooth connections: Adjacent toolpaths connect smoothly through arcs.

- No sudden stops or starts: Keeps the tool movement speed stable, avoiding frequent acceleration and deceleration.

2. Dynamic Cutting Parameter Adjustment

- Load sensing: Monitors spindle load, cutting force, and vibrations in real-time.

- Intelligent adjustment: Automatically adjusts the cutting step distance and depth according to the load.

- Constant removal rate: Maintains a stable material removal rate in different areas.

3. Optimization of Material Removal Rate

- Treatment of concave areas: Automatically reduces the cutting step distance in concave material areas.

- Treatment of convex areas: Appropriately increases the cutting step distance in convex material areas.

- Load balancing: Ensures uniform machine load throughout the machining process.

Technical Implementation Methods

1. Side Edge Cutting Method

- Tool selection: Uses tools with side edges, such as tungsten carbide or high-speed steel tools.

- Cutting strategy: Utilizes the side edges of the tool for cutting, allowing for larger cutting depths.

- Layered machining: For harder materials, combines the main Z-axis cutting depth with the sub-Z-axis cutting depth.

2. Bottom Edge Cutting Method

- Application scenarios: Ideal for surface finishing and machining thin-walled parts.

- Advantages: Although the Z-axis cutting depth is small, it still maintains high machining efficiency.

- Surface quality: Achieves a better surface finish.

Advantages of Ripple Milling

Improved Machining Efficiency

- 60-70% efficiency increase: Reduces machining time by 40-50% compared to traditional methods.

- Case data: In one actual application, traditional machining took 52 minutes, while Ripple Milling only took 20 minutes.

- Production benefits: Greatly shortens the production cycle and improves equipment utilization.

Protection of Machine Tools and Cutting Tools

- Stable load: Avoids sudden load spikes at corners in traditional machining.

- Reduced vibrations: The smooth toolpath significantly decreases machining vibrations.

- Extended tool life: Reduces tool impacts and wear, prolonging tool life.

- Lower maintenance costs: Decreases machine breakdowns and repair needs.

Enhanced Machining Quality

- Better surface finish: The rippled toolpath reduces machining marks.

- Higher dimensional accuracy: The stable cutting process improves dimensional consistency.

- Improved geometric tolerances: Reduces machining errors caused by load changes.

- Lower residual stress: The uniform distribution of cutting force decreases residual stress in the workpiece.

Real-world Application Cases

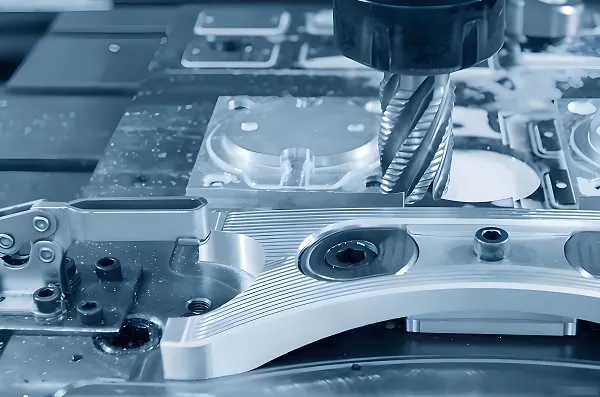

Mold Manufacturing Industry

- Machining complex cavities: Efficiently completes rough machining for complex mold cavity structures.

- Machining hard materials: Performs well when machining mold steels with a hardness above HRC45.

- Case results: After adopting Ripple Milling, a mold factory reduced the mold machining time from 72 hours to 24 hours.

Aerospace Manufacturing

- Machining titanium alloys: Effectively controls the cutting temperature when machining difficult materials like titanium alloys and high-temperature alloys.

- Machining complex structural parts: Provides an ideal machining solution for complex parts such as aircraft engine blades.

- Accuracy assurance: Ensures the machining accuracy and surface quality of key components.

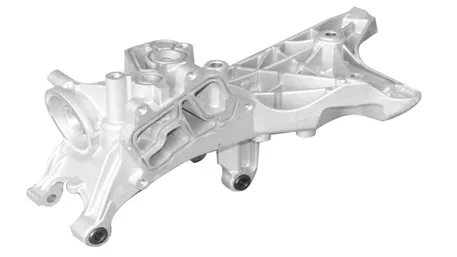

Automotive Component Production

- Mass production: Significantly improves production efficiency in the mass production of automotive components.

- Engine parts: Greatly enhances the machining efficiency of complex parts like engine blocks and cylinder heads.

- Cost control: Reduces production costs and increases market competitiveness.

Application Conditions of Ripple Milling

Equipment Requirements

- CNC system requirements: Requires a modern CNC system that supports complex toolpaths.

- Servo system: High-precision servo drives and high-resolution encoders.

- Spindle performance: Sufficient spindle power and rigidity to withstand heavy cutting loads.

- Stability: The machine tool should have high overall rigidity and stability to reduce vibration effects.

Programming Software

- WorkNC: The software that first proposed the concept of Ripple Milling.

- Mastercam: Supports similar dynamic milling functions.

- UG NX: Has advanced variable-axis milling capabilities.

- PowerMill: Offers efficient rough machining strategies.

Operator Requirements

- Technical training: Must receive specialized training in Ripple Milling.

- Experience accumulation: Gain practical experience in machining different materials and parts.

- Parameter optimization: Be able to optimize machining parameters according to actual conditions.

- Problem-solving: Have the ability to handle issues that arise during the machining process.