Development Trends of Ripple Milling

Increased Intelligence

In the future, Ripple Milling will become more intelligent:

- AI algorithm application: Incorporates artificial intelligence algorithms to optimize cutting parameters.

- Adaptive control: Achieves fully autonomous machining process control.

- Predictive maintenance: Predicts equipment maintenance needs based on machining data.

Integration with Other Technologies

Ripple Milling will deeply integrate with other advanced technologies:

- Five-axis linkage: Combines with five-axis machining technology to expand application scope.

- Additive manufacturing: Integrates with 3D printing technology for hybrid machining.

- Digital twin: Creates a digital twin model of the machining process to optimize machining strategies.

Expansion of Application Areas

The application areas of Ripple Milling will continue to expand:

- Medical equipment: Applied to machining high-precision medical equipment parts.

- New energy: Meets the manufacturing needs of new energy equipment.

- Micro-nano machining: Expands its application to the micro machining field.

Practical Application Guide

Machining Parameter Settings

Correctly setting machining parameters is crucial for applying Ripple Milling successfully:

- Cutting speed: Select according to material properties and tool performance.

- Feed rate: Ripple Milling allows for higher feed rates.

- Cutting depth: Determine based on machine tool rigidity and tool strength.

- Step distance control: Automatically optimized by the software, usually 5-15% of the tool diameter.

Tool Selection Recommendations

Tool selection greatly affects machining results:

- Tool material: Choose suitable tool materials based on the machining material.

- Tool geometry: Select tool geometries suitable for Ripple Milling.

- Tool coating: Use advanced tool coating technologies to extend tool life.

Common Problems and Solutions

Possible issues when applying Ripple Milling:

- Machining vibrations: Check machine tool rigidity and optimize cutting parameters.

- Poor surface quality: Adjust step distance parameters and improve the toolpath.

- Excessive tool wear: Check cutting parameters and optimize tool selection.

- Lower-than-expected machining efficiency: Re-optimize machining strategies and parameters.

Conclusion

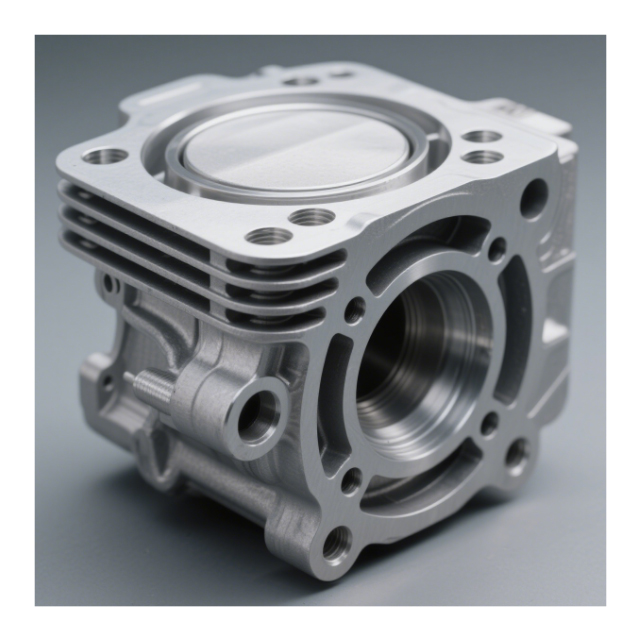

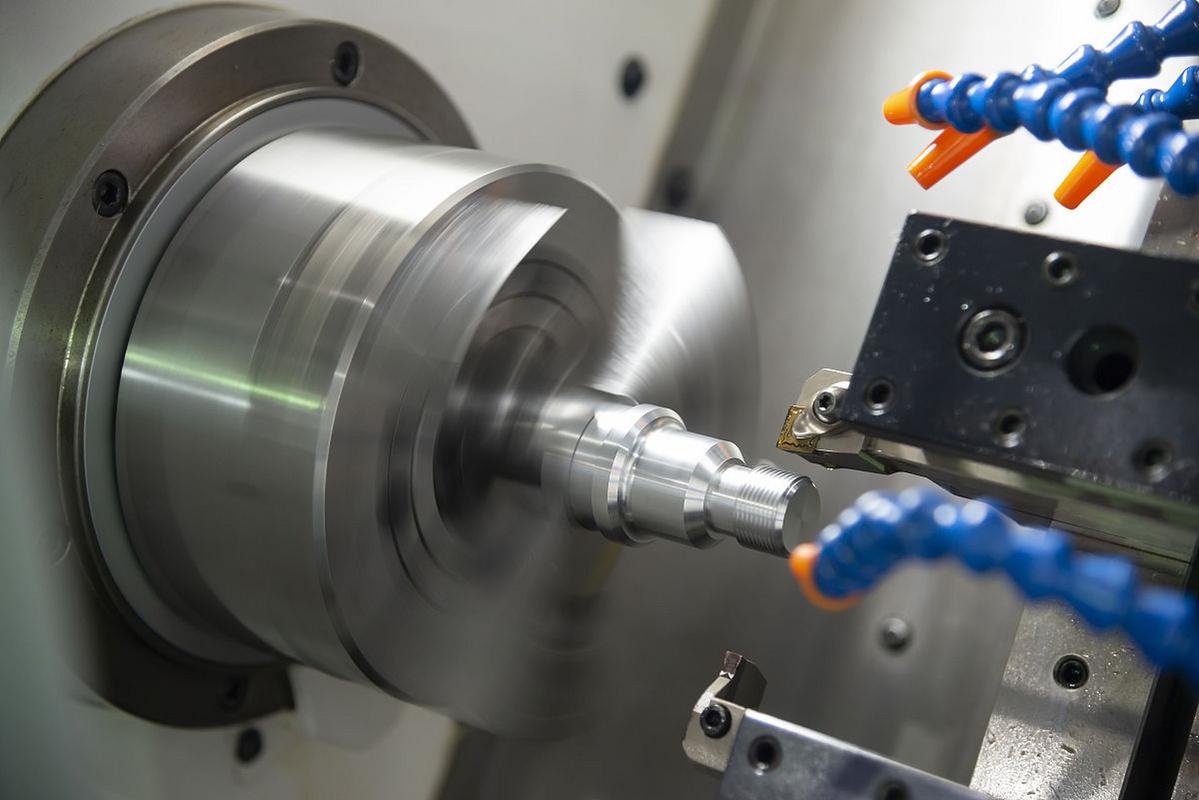

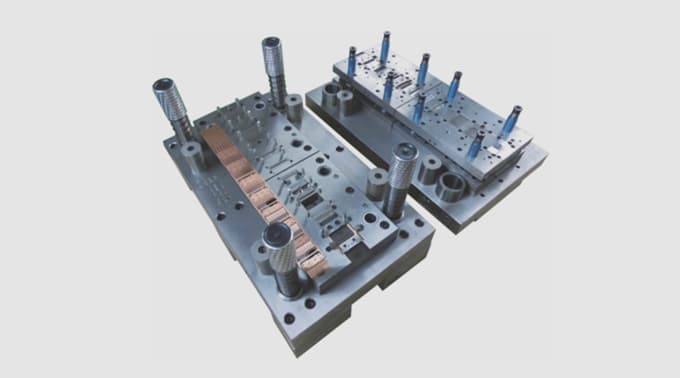

Ripple Milling is key to improving efficiency and reducing costs in CNC machining. If you need customized CNC parts, Xiamen Gold Cattle offers professional services:

- Advanced technology: Adopts cutting-edge processes like Ripple Milling to ensure machining accuracy and efficiency.

- Flexible customization: Customizes various complex parts to meet diverse production needs.

- High-quality service: Provides one-stop services from design to delivery, helping businesses reduce costs and increase efficiency.

We look forward to collaborating with you and using our technical strength to boost your business’s competitiveness!