Screw Injection Molding: The Real Deal

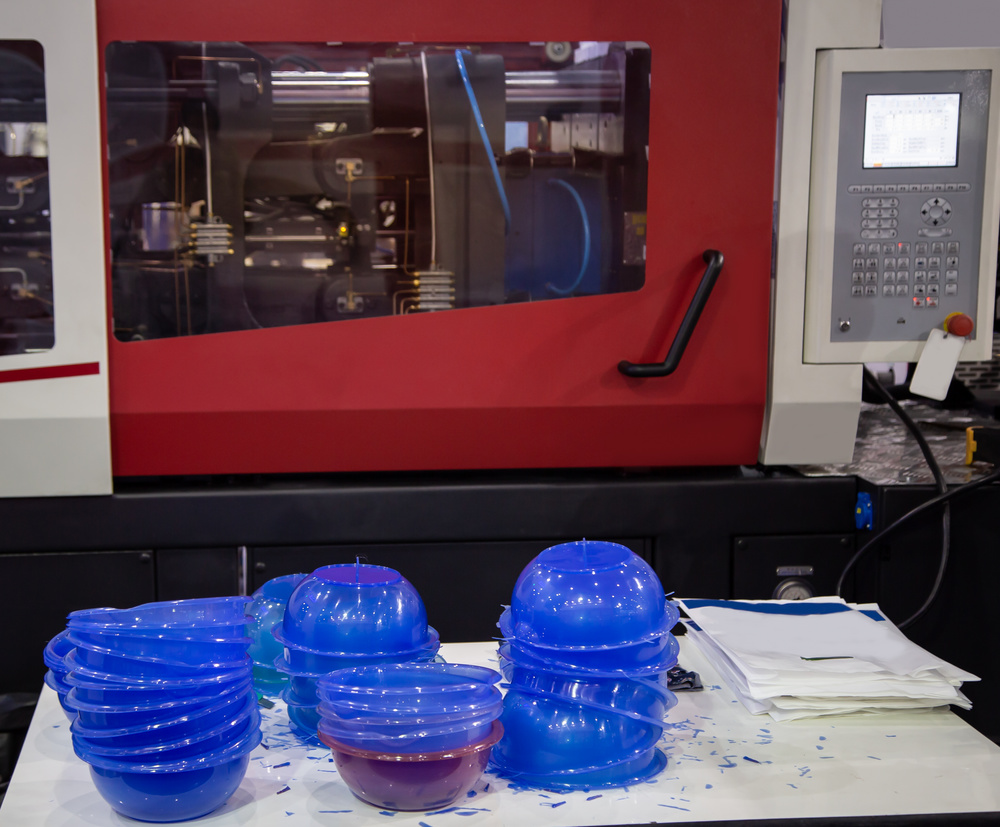

Dude, this is how they make ALL your plastic stuff – from phone cases to car parts. Let’s break down the actual process

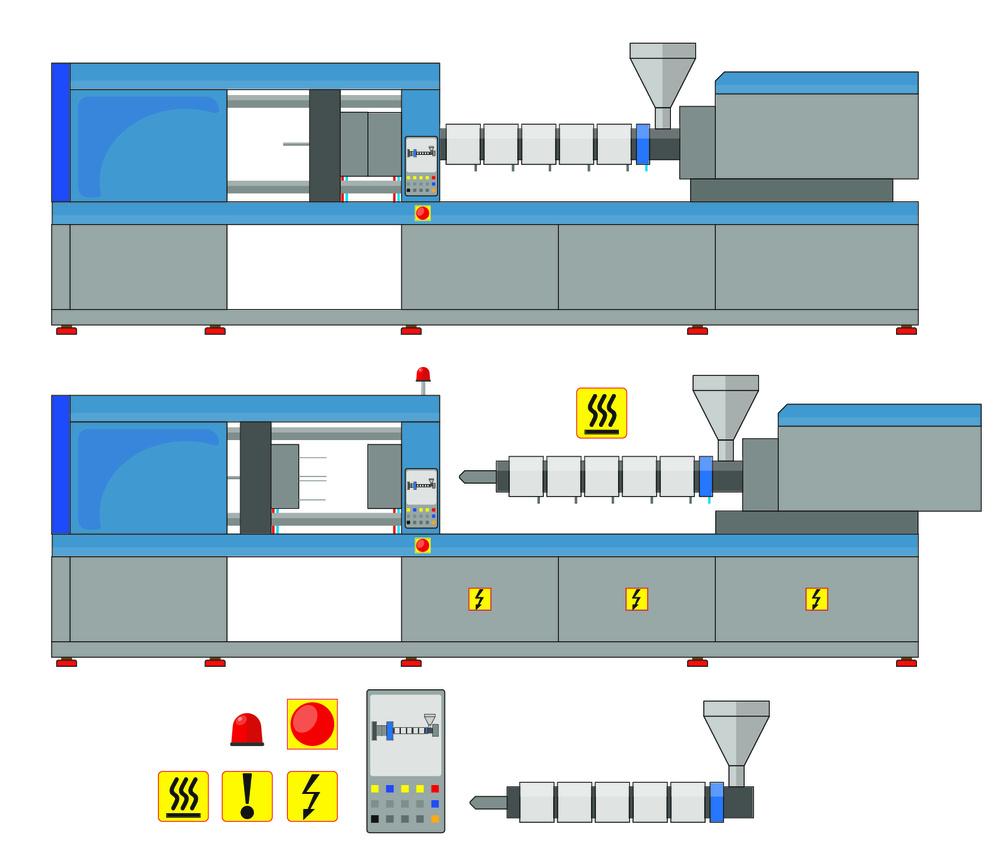

1. The Machine – What The Heck Is This Thing?

Bro, this machine is a BEAST!

Let me tell you – screw injection molding machines are the real deal in plastic manufacturing. They’re like the industrial version of a fancy 3D printer, but on steroids.

Main Components (The Important Stuff)

- Screw & Barrel: The heart of the machine – melts and pushes plastic

- Injection Unit: Controls the pressure and speed of plastic injection

- Clamping Unit: Holds the mold shut with tons of force

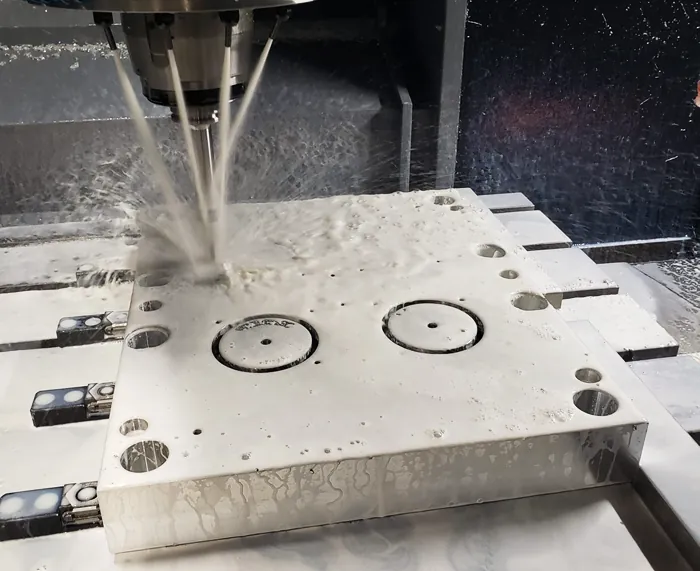

- Mold: The actual shape your plastic part takes

- Control System: The brain – runs all the parameters

Fun Fact About Machine Sizes

Tiny machines: 5-50 ton clamping force (for small parts)

Big boys: 500-5000 ton clamping force (for car bumpers and stuff)

*That’s like having 50 elephants sitting on your mold!

2. The Process – Step By Step (No Boring Stuff)

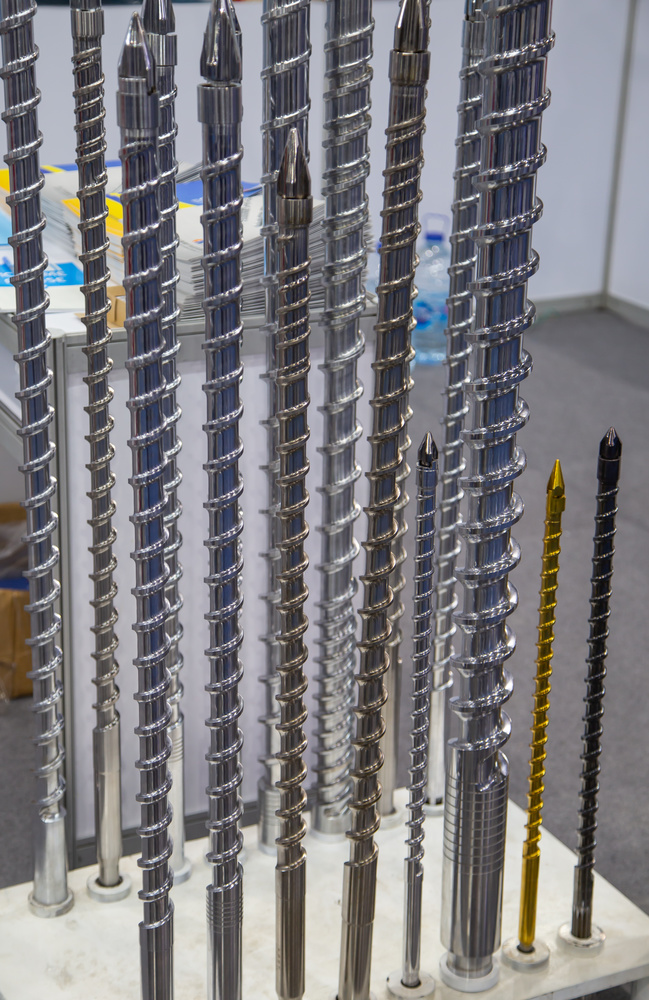

3. The Screw – This Thing Is More Complex Than You Think!

Dude, screws aren’t just metal rods!

The screw design is CRUCIAL to getting good parts. It’s like the engine of the whole machine – mess this up and your parts will suck.

Key Screw Parameters (The Nerd Stuff)

- L/D Ratio: Length to Diameter – usually 18-25:1 for general purpose

- Compression Ratio: 2.5-4:1 – how much plastic gets compressed

- Channel Depth: Deeper = more plastic, shallower = better mixing

- Flight Geometry: The shape of the screw threads

Pro Tip From A Veteran

“If you’re processing sticky materials like PVC, get a screw with a barrier flight. Trust me, you’ll thank me later when your parts don’t have burn marks.”

– Mike, 25-year injection molding engineer

Screw Types For Different Materials

| Material Type | Best Screw Design | L/D Ratio |

|---|---|---|

| General Purpose (PP, PE) | Standard | 18-22:1 |

| Engineering Plastics (ABS, PC) | Barrier | 22-26:1 |

| High Viscosity (PVC, PMMA) | Low Compression | 16-20:1 |

| Glass Filled | Wear Resistant | 20-24:1 |

4. Materials – Choosing The Right Plastic Is Make Or Break

Common Injection Molding Materials (With Actual Data)

Polypropylene (PP)

Melting Temp: 160-220°C

Density: 0.90-0.91 g/cm³

Tensile Strength: 20-30 MPa

Shrinkage: 1.0-2.5%

Used for: Food containers, toys, car parts

ABS

Melting Temp: 200-250°C

Density: 1.04-1.07 g/cm³

Tensile Strength: 40-50 MPa

Shrinkage: 0.4-0.9%

Used for: Lego, phone cases, tool handles

Nylon (PA6/PA66)

Melting Temp: 220-260°C

Density: 1.13-1.15 g/cm³

Tensile Strength: 70-90 MPa

Shrinkage: 0.8-1.5%

Used for: Gears, bearings, car parts

Material Processing Tips (From Someone Who’s F***ed Up Before)

- Drying is CRITICAL: Moisture = bubbles and defects. Dry PA for 4-6hrs at 80-100°C!

- Don’t overheat: Burned plastic smells like hell and ruins parts. Stick to recommended temps.

- Screw speed matters: Too fast = shear heating, too slow = poor mixing. Find the sweet spot.

- Colorants affect flow: Adding color can change how plastic flows – test first!

5. Common Defects – Why Your Parts Suck And How To Fix Them

Defects Happen – Here’s How To Fix Them

Flow Lines (The Streaky Ones)

Streaks or waves on part surface where plastic flows meet.

Fixes:

- Increase melt temperature

- Increase injection speed

- Optimize gate location

Sink Marks (The Dents)

Depressions where plastic shrinks too much during cooling.

Fixes:

- Increase packing pressure

- Extend packing time

- Optimize wall thickness

Flash (The Extra Plastic)

Plastic that squeezes out of mold parting lines.

Fixes:

- Decrease injection pressure

- Check mold alignment

- Clean mold surfaces

Bubbles (The Holes)

Air pockets or trapped gas in the part.

Fixes:

- Dry material thoroughly

- Decrease melt temperature

- Use venting in mold

Pro Troubleshooting Checklist (Save This!)

First Check:

- Material drying

- Mold temperature

- Injection pressure

Second Check:

- Screw speed

- Back pressure

- Cooling time

Last Resort:

- Mold modifications

- Screw changes

- Material changes

6. Industry Standards – The Rules You HAVE To Follow

Standards That Matter (And Why)

ISO Standards

- ISO 294: Plastics – Injection molding molds

- ISO 10350: Plastics – Tensile properties

- ISO 178: Plastics – Flexural properties

- ISO 180: Plastics – Izod impact strength

ASTM Standards

- ASTM D3641: Plastic materials injection molding

- ASTM D638: Tensile properties of plastics

- ASTM D790: Flexural properties of plastics

- ASTM D256: Izod impact testing

Industry Specific

- UL 94: Flammability of plastic materials

- IEC 60695: Fire hazard testing

- FDA 21 CFR: Food contact materials

- RoHS: Restriction of hazardous substances

Testing Requirements (The Expensive Part)

Dimensional Testing:

CMM, optical comparators, gauges

Mechanical Testing:

Tensile, flexural, impact strength

Environmental Testing:

Temperature cycling, humidity, UV exposure

Why Standards Matter (Spoiler: It’s Not Just Paperwork)

Customer trust: Standards show you know what you’re doing

Legal protection: Compliance prevents lawsuits

Quality control: Standards ensure consistent parts

*Based on 2025 industry data (For reference only)

7. Machine Sizes & Costs – How Much This Stuff Actually Costs

Machine Costs (The Real Numbers)

Small Machines (50-100 ton)

Price: $20,000-$50,000

Shot weight: 50-100 grams

Applications: Small parts, prototypes

Good for: Startups, small batches

Medium Machines (100-500 ton)

Price: $50,000-$200,000

Shot weight: 100-500 grams

Applications: Consumer goods, auto parts

Good for: Medium production runs

Large Machines (500+ ton)

Price: $200,000-$1,000,000+

Shot weight: 500+ grams

Applications: Car bumpers, large containers

Good for: High volume production

Operating Costs (The Ongoing Expenses)

Material costs:

$0.50-$3.00 per kg

Energy costs:

$5-$20 per hour

Labor costs:

$15-$30 per hour

Maintenance:

2-5% of machine cost annually

*Prices in USD, based on 2025 market rates (For reference only)

8. Future Trends – Where Is This Industry Going?

The Future Of Injection Molding Is Here

Smart Molding (Industry 4.0)

Real-time monitoring with IoT sensors that adjust parameters automatically.

- AI-driven process optimization

- Predictive maintenance

- Cloud-based data analytics

Sustainable Materials

Biodegradable and recycled plastics are becoming mainstream.

- Bio-based polymers (PLA, PHA)

- 100% recycled materials

- Carbon-neutral production

Advanced Technologies

New processes that push the boundaries of what’s possible.

- Micro-injection molding

- Gas-assisted injection molding

- Multi-material molding

What This Means For You

The injection molding industry is evolving FAST. If you’re in this business, you need to

adapt or get left behind. Invest in training, upgrade your equipment, and stay

ahead of the curve!

So, What Did We Learn?

Screw Injection Molding Is Awesome (But Complex)

The Good Stuff

- Super efficient for high volume production

- Consistent, high-quality parts

- Can make complex shapes

- Wide range of materials available

The Challenges

- High initial investment cost

- Requires skilled operators

- Mold costs can be expensive

- Setup time for new parts

Final Advice From A Pro

“Start small, learn the basics, and don’t be afraid to experiment.

Every molding expert started by making crappy parts – the difference

is they kept trying until they got it right.”

– Sarah, 18-year injection molding specialist