Injection molding thrives on efficiency—minimizing waste, reducing cycle times, and ensuring consistent part quality. For manufacturers seeking a middle ground between traditional cold runners (high waste) and full hot runners (high upfront cost), semi-hot runner mold customization emerges as the smart solution. At Goldcattle, with 26 years of mold engineering expertise, we specialize in designing custom semi-hot runner systems that combine the best of both worlds: reduced material waste, faster cycles, and lower tooling costs. Let’s unpack how these molds work, their key advantages, and why Goldcattle is your trusted partner for tailored semi-hot runner solutions.

How Semi-Hot Runner Molds Work: The Best of Both Worlds

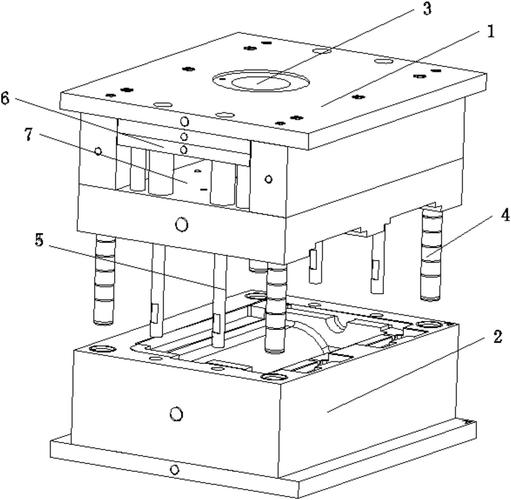

Semi-hot runner molds bridge the gap between cold and full hot runner systems. In traditional cold runner molds, molten plastic flows through unheated channels, leaving solidified “runners” (waste material) that require trimming. Full hot runners keep channels fully heated to prevent solidification, eliminating runners but demanding higher tooling investment.

Semi-hot runners take a hybrid approach: selective heating of critical runner sections (like main channels or large branches) while leaving smaller secondary channels unheated. This design reduces waste by 30–50% compared to cold runners while costing 20–40% less than full hot runners . The result? Efficient production for mid-to-high volume runs without breaking the budget.

Key Advantages of Custom Semi-Hot Runner Molds

1. Reduced Material Waste & Cost Savings

By heating primary flow paths, semi-hot runners keep molten plastic from solidifying in the largest, most wasteful runner sections. For a client producing PP plastic caps (50mm diameter), Goldcattle’s custom semi-hot runner mold cut runner waste from 25g per cycle to just 8g—saving 68% on raw material costs annually . This adds up: for 1 million parts, that’s 17,000kg of plastic saved.

2. Faster Cycle Times for Higher Output

Heated channels reduce pressure drop and improve flow, allowing shorter cooling times. A case study with a nylon automotive connector showed cycle times dropping from 45 seconds (cold runner) to 32 seconds with a semi-hot runner system—boosting daily production by 40% . This efficiency is critical for meeting tight delivery deadlines in industries like consumer electronics and automotive.

3. Versatility Across Materials & Part Sizes

Semi-hot runners excel with mid-range viscosity materials like PP, ABS, PS, and PA66—common in household appliances, toys, and packaging . Goldcattle’s custom designs accommodate parts from 5g to 500g, from small electrical housings to medium-sized container lids. For example, we optimized a semi-hot runner mold for a 150g ABS cosmetic jar, ensuring uniform wall thickness (±0.1mm) across 10,000+ daily units.

4. Lower Tooling Cost vs. Full Hot Runners

Full hot runners require complex heating elements, temperature controllers, and precision machining, driving up tooling costs. Semi-hot runners use simpler, targeted heating (often in main channels only), reducing tooling investment by 20–30% . This makes them ideal for businesses scaling production or testing new part designs before committing to full hot runner tooling.

Goldcattle’s Semi-Hot Runner Customization Process

Crafting a high-performance semi-hot runner mold demands precision engineering and material expertise. Our process ensures your mold meets exact production needs:

1. Design & DFM Analysis

We start by analyzing your part CAD files, material type, and production volume. For a client’s 8-cavity PP food container mold, our engineers recommended heating the main runner (12mm diameter) while leaving sub-runners unheated—optimizing waste reduction without overcomplicating the design.

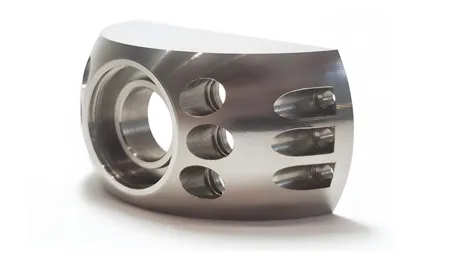

2. Material Selection for Durability

Mold plates use S50C or P20 steel (HRC 28–32) for durability, while heating elements are made from corrosion-resistant copper alloys. We select heater wattages (typically 50–150W per zone) based on material viscosity—higher wattages for thicker materials like PC to prevent cooling .

3. Precision Machining & Assembly

Runners are machined to ±0.02mm dimensional accuracy using 5-axis CNC centers, ensuring smooth flow. Heating elements are embedded with 0.1mm clearance to prevent overheating, and thermocouples are positioned 5mm from runner walls for precise temperature control (±2°C) .

4. Testing & Validation

Each mold undergoes 50–100 trial shots to fine-tune heating zones and pressure settings. For a recent ABS toy part mold, we adjusted heater temperatures from 180°C to 195°C to eliminate flow lines, ensuring consistent part appearance.

Applications: Where Semi-Hot Runner Molds Shine

- Consumer Packaging: Bottles, caps, and lids (PP/PE materials) benefit from reduced waste and fast cycles.

- Electrical Housings: ABS/PC components requiring uniform wall thickness and minimal flash.

- Automotive Small Parts: Nylon clips and connectors needing cost-efficient mid-volume production.

- Household Appliances: PS/PP knobs, handles, and covers with consistent surface finishes.

FAQs About Semi-Hot Runner Mold Customization

Q: How does a semi-hot runner differ from a full hot runner?

A: Semi-hot runners heat only critical runner sections (e.g., main channels), leaving smaller runners unheated. This reduces waste less than full hot runners but costs significantly less in tooling.

Q: What production volumes are semi-hot runners best for?

A: They excel for mid-to-high volumes: 50,000–500,000 parts annually. Below 50,000, cold runners may be more cost-effective; above 500,000, full hot runners often justify their investment.

Q: Can semi-hot runners handle heat-sensitive materials?

A: Yes, with careful temperature control. We limit heater temps to 180–220°C for materials like PVC (sensitive to overheating) and use shorter residence times to prevent degradation .

Q: How long does custom semi-hot runner mold production take?

A: Typically 6–8 weeks for standard designs. Complex molds (16+ cavities or exotic materials) may take 10–12 weeks. Goldcattle offers expedited options (4–6 weeks) for urgent projects.

Q: What maintenance do semi-hot runners require?

A: Annual checks of heating elements and thermocouples, plus cleaning of unheated runner sections to prevent buildup. Our molds include easy-access panels to simplify maintenance.

Ready to Optimize Your Injection Molding Process?

Semi-hot runner mold customization delivers the sweet spot of efficiency, cost, and performance for mid-to-high volume production. At Goldcattle, we combine engineering expertise with advanced machining to create molds that reduce waste, speed cycles, and fit your budget.

Visit https://www.xmgoldcattle.com/ to discuss your part design or request a free semi-hot runner feasibility analysis. Let’s build a mold that elevates your production game.

Got a part that could benefit from reduced waste or faster cycles? Share your project details below—our mold engineers are ready to help!