Silicone injection molding is an advanced plastic molding technology specifically designed to process silicone materials. This technique works by heating the silicone material to a molten state and then injecting it under high pressure into a pre-designed mold, where it is cooled and cured to form the desired product shape. Silicone injection molding technology has a series of significant advantages, making it widely used in a number of industries.

1. Principle of silicone injection molding technology

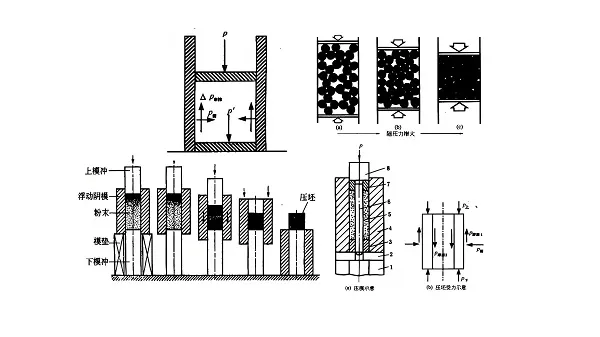

The core of silicone injection molding technology lies in the three main steps of silicone injection, curing and demolding. First of all, liquid silicone or pre-treated silicone raw materials are fed into the hopper of the injection molding machine, through the role of heat and pressure, silicone is injected into the cavity of the mold, filling the entire mold. Subsequently, the silicone cures in the mold over a period of time to form the desired product shape. Finally, the mold is opened and the finished silicone product is taken out and subsequently processed.

2. Silicone injection molding process

The process of silicone injection molding includes the following steps:

Prepare the mold: according to the product design requirements for the production of molds, including the upper and lower molds, mold kernel and so on.

Prepare silicone material: choose the suitable silicone material, and according to the product requirements for the proportion and mix well.

Heat the silicone material: Put the silicone material into the hopper of the injection molding machine, and heat the silicone material to the molten state through the heating system.

Injecting silicone material: inject the molten silicone material into the injection nozzle of the injection molding machine, and inject the silicone material into the mold under high pressure through the movement of the nozzle.

Cooling and curing: The silicone material injected into the mold is cooled and cured in the mold.

Take out the finished product: When the silicone material is completely cured, open the mold, take out the finished product and carry out subsequent processing (such as deburring, cleaning, etc.).

3. Silicone injection molding materials

3.1 Basic characteristics of silicone injection molding materials

High temperature resistance: silicone injection molding materials can maintain stable performance in a high temperature environment, not easy to deformation or failure.

Low temperature resistance: Similarly, in low temperature conditions, silicone injection molding materials can also maintain good flexibility and elasticity.

Corrosion resistance: Silicone materials have excellent corrosion resistance to a variety of chemicals, and can be used for a long time in harsh environments.

Biocompatibility: Some silicone injection molding materials have been specially treated to have good biocompatibility and are suitable for use in the medical field.

High Transparency: Some silicone injection molding materials have high transparency and can be used for products that require a transparent or translucent appearance.

Easy processing: silicone injection molding materials have good fluidity and plasticity, easy injection molding.

3.2 Common types of silicone injection molding materials

Liquid Silicone Rubber (LSR): Liquid silicone rubber is one of the most commonly used materials in silicone injection molding, which has excellent fluidity and molding properties, and can produce high-precision, high-quality silicone products. Liquid silicone will cure into silicone rubber at high temperatures, and its curing process can be controlled by a catalyst.

High Elasticity Silicone Particles: This is a high elasticity and high transparency silicone material which is commonly used in the injection molding process to prepare a variety of silicone products with complex shapes and high elasticity.

Special silicone: according to the specific application requirements, you can also choose silicone materials with special properties, such as conductive silicone, flame retardant silicone and so on.

4. Advantages of silicone injection molding

Fast molding speed: silicone injection molding process can complete the product molding process in a short period of time, greatly improving production efficiency.

High molding accuracy: silicone injection molding can ensure the dimensional accuracy and surface quality of the product to meet the high precision requirements of the application scenario.

Uniform force on the product: Since the silicone material can flow evenly and fill the mold during the injection molding process, the finished product is subjected to a more uniform force, which improves the durability and reliability of the product.

Excellent material performance: Silicone material itself has excellent characteristics such as high temperature resistance, low temperature resistance, corrosion resistance, good flexibility, etc., which are retained and further enhanced in the injection molding process.

5. Application areas of silicone injection molding

Silicone injection molding technology is widely used in many industries, including but not limited to:

Medical Devices: Silicone material has become an ideal choice for manufacturing artificial organs, medical infusion sets, medicine bottles and other medical devices due to its good biocompatibility and corrosion resistance.

Electronic products: Silicone materials have good electrical insulation properties and high temperature resistance, and can be used to manufacture sealing gaskets, buttons and other parts of electronic products.

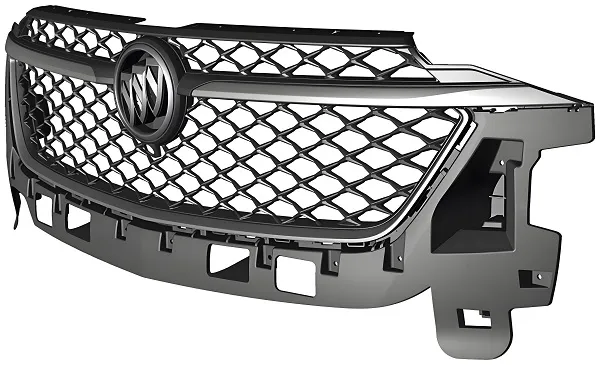

Automotive industry: Silicone materials are widely used in automobile manufacturing to make airbags, catheters, seals and other parts, which need to be resistant to high temperature, low temperature, corrosion and have good sealing and durability.

Household goods: silicone materials can be used to manufacture a variety of household goods such as silicone kitchenware, silicone toys, etc. These silicone products not only have high temperature resistance, low temperature resistance, corrosion resistance and other properties but also has a soft, non-slip, easy to clean and other characteristics.

Silicone injection molding FAQ

1. Can the hardness of silicone injection molded products be adjusted?

Answer: Yes, the hardness of silicone injection molded products can be adjusted by adjusting the formula of silicone raw materials. Common silicone hardness ranges from a very soft 20 Shore A to a very hard 80 Shore A. The hardness of silicone injection molded products can be adjusted by changing the crosslinking in the silicone raw material. Different hardness requirements can be realized by changing the cross-linking agent content, filler types and ratios in the silica gel.

2. What is the transparency of silicone injection molded products?

Answer: The transparency of silicone injection molded products depends on the silicone raw material used and its formulation. Some specially formulated silicone can achieve high transparency, which is suitable for products that need transparent appearance, such as transparent parts for medical devices, transparent buttons for electronic products, etc. However, the addition of certain fillers or pigments may reduce the transparency of silicone.

3. What is the abrasion resistance of silicone injection molded products?

Answer: The abrasion resistance of silicone injection molded products depends on the formulation of the silicone and the environment in which the products are used. Generally speaking, silicone has good abrasion resistance and can resist abrasion and scratches to a certain extent. However, for application scenarios that require particularly high abrasion resistance, it may be necessary to further improve the abrasion resistance of the silicone gel by adding abrasion-resistant agents or using special formulations.

4. How environmentally friendly are silicone injection molded products?

A: Silicone injection molded products excel in environmental friendliness. Silicone material itself is non-toxic and harmless, does not contain harmful substances, and has less impact on the environment during production and disposal. In addition, silicone products can be recycled and reused, reducing the burden on the environment. Therefore, silicone injection molded products are widely used in medical, food and other fields with high environmental requirements.