What is Silicone Injection Molding?

Silicone injection molding is a manufacturing process. It uses liquid silicone material, which is injected into a mold under high pressure using a machine, then heated to cure and form the desired product shape.

Simply put, it’s like using a cookie cutter, but with special silicone material and professional machinery.

Why Choose Silicone Injection Molding?

Material Advantages

- Heat Resistant: Can withstand very high and very low temperatures

- Soft and Flexible: Like rubber, can bend easily

- Safe and Non-toxic: Harmless to humans, suitable for medical and baby products

- Durable: Resistant to aging, long service life

- Waterproof: Doesn’t absorb water, suitable for humid environments

Manufacturing Advantages

- High Precision: Accurate product dimensions

- Fast Production: Can produce large quantities quickly

- Design Flexibility: Can create complex shapes

- Cost-effective: Suitable for mass production

The Silicone Injection Molding Process

Step 1: Material Preparation

Silicone material has two parts:

These two parts need to be mixed in a 1:1 ratio.

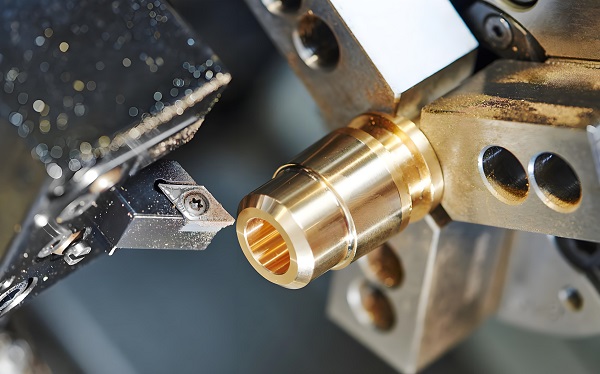

Step 2: Mold Design and Production

According to the product shape required by the customer, design and produce a metal mold. The mold, like a cookie cutter, determines the final shape of the product.

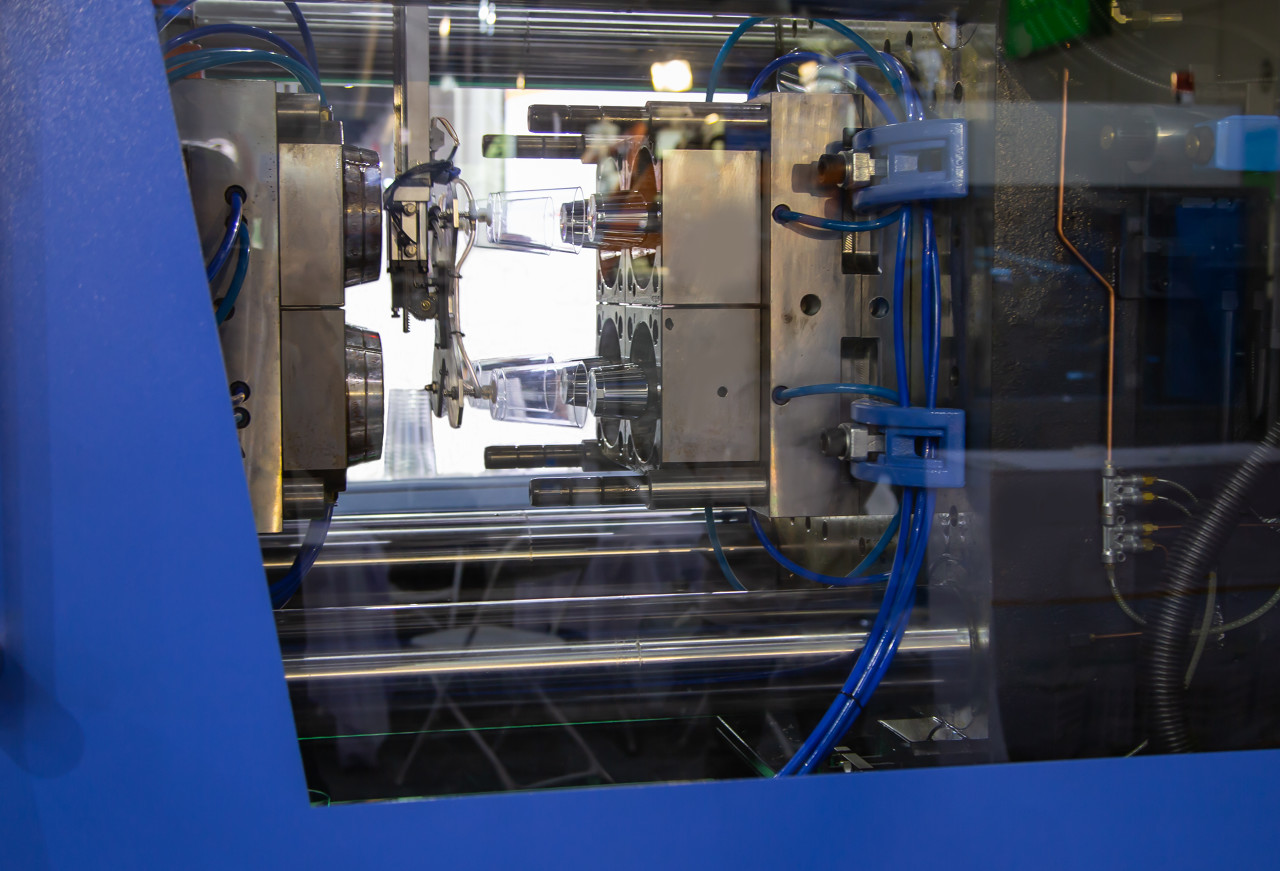

Step 3: Injection Process

- Pour the mixed silicone material into the machine

- The machine heats the material to the appropriate temperature

- Inject the material into the mold under high pressure

- The mold maintains high temperature to cure the material

Step 4: Product Removal

- Open the mold after cooling

- Take out the molded silicone product

- Remove excess material (flash)

- Inspect product quality

Step 5: Post-processing

As needed:

- Surface treatment (polishing, printing)

Our Service Content

Design Services

- Product design consultation

- Mold design and production

Material Selection

Provide various silicone materials:

- High temperature resistant silicone

Manufacturing Services

Post-processing Services

Application Fields

Medical Industry

- Medical device accessories

Automotive Industry

Electronics Industry

Daily Necessities

- Sports equipment accessories

Industrial Equipment

Why Choose Us?

Professional Experience

- 26 years of manufacturing experience

- National high-tech enterprise

- Professional engineering team

- Advanced production equipment

Quality Assurance

- ISO9001 quality management system certification

- SGS, RoHS, CE and other international certifications

- Strict quality control processes

Service Advantages

- One-stop service (from design to production)

- Quick response to customer needs

- Flexible production arrangements

- Professional technical support

Customer Base

- Serving customers in multiple industries

- Both domestic and international customers

- Long-term cooperative relationships

Our Equipment Advantages

Advanced Equipment

- High-precision injection molding machines

- Automated production lines

- Precision testing equipment

- Clean production environment

Technical Capabilities

- 5-axis machining equipment with precision up to ±0.005mm

- Fully automated production lines

- Intelligent quality control system

- Environmental protection production processes

Quality Commitment

Material Guarantee

- Using high-quality silicone materials

- Materials meet international standards

- Can provide material certification reports

- Environmentally friendly materials, meeting RoHS requirements

Manufacturing Guarantee

- Strictly produce according to customer requirements

- Quality records for each batch of products

- Provide sample confirmation

After-sales Guarantee

- Free repair for product quality issues

- Technical support and consultation

- Regular customer return visit

- Continuous service improvement

Contact Us

If you need silicone injection molding services, please contact us:

Company Name: Xiamen Goldcattle

Address: Xiamen City, Fujian Province, China

Phone: Please visit our official website for the latest contact information

Service Process

- Requirement Communication: Understand your product requirements

- Solution Design: Provide technical solutions and quotations

- Sample Production: Make samples for your confirmation

- Mass Production: Start mass production after sample confirmation

- Delivery Service: Deliver products on time and provide after-sales service

Quick Quotation

Provide the following information for a quick quote:

- Product drawings or samples

- Delivery time requirements

We look forward to cooperating with you and providing you with high-quality silicone injection molding services!

Last updated: October 2025