As an important part of the modern manufacturing industry, silicone plastic molds play a key role in many fields with their unique material properties and exquisite manufacturing techniques. The purpose of this brochure is to introduce the design, manufacture and application of silicone plastic molds in detail, to help you gain a deeper understanding of the core technologies and advantages in this field.

Overview of silicone plastic molds

Silicone plastic mold is based on the silicone material, through the precision processing of the mold. Silicone, as a high-performance elastic material, has excellent resistance to high temperature, chemical corrosion, high resilience and good sealing performance, these characteristics make silicone molds have a wide range of applications in injection molding, vacuum vacuum molding, 3D printing and other fields.

the manufacturing process of silicone mold

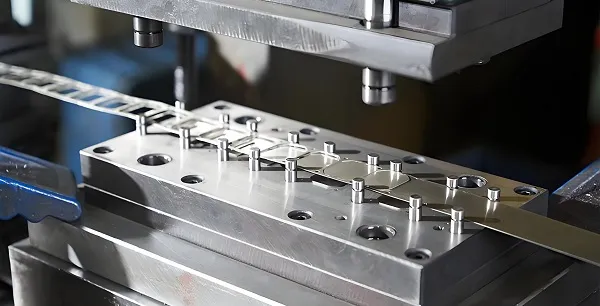

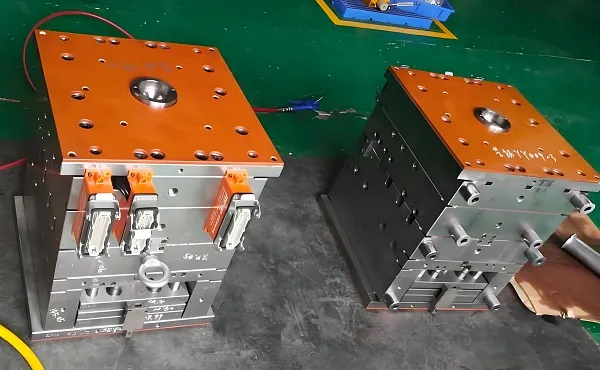

Mold design: According to the product demand and process requirements, the three-dimensional design of the mold, including the design of the parting surface, gate position, cooling system and other key elements.

Mould processing: using CNC machining, EDM and other high-precision manufacturing processes, the mold is finely processed to ensure the dimensional accuracy and surface quality of the mold.

Silicone casting: Liquid silicone is injected into the mold cavity and cured for a period of time to form the silicone mold.

Mould testing and optimization: performance testing of silicone moulds, including temperature resistance, elasticity recovery, sealing, etc., and optimization and adjustment according to the test results.

the advantages of silicone mold

High elasticity: Silicone molds have excellent elasticity, which can adapt to the production of complex shapes and reduce deformation and breakage during the production process.

High temperature resistance: silicone material can maintain stable performance in high temperature environment, suitable for high temperature injection molding and other processes.

Chemical resistance: Silicone molds have good corrosion resistance to a variety of chemicals and are suitable for molding a variety of plastics and resins.

Easy to release: the surface of silicone mold is smooth and easy to release, reducing product surface scratches and damage.

Long life: silicone molds have high abrasion resistance and anti-aging properties, and can maintain excellent performance for a long time.

the application areas of silicone mold

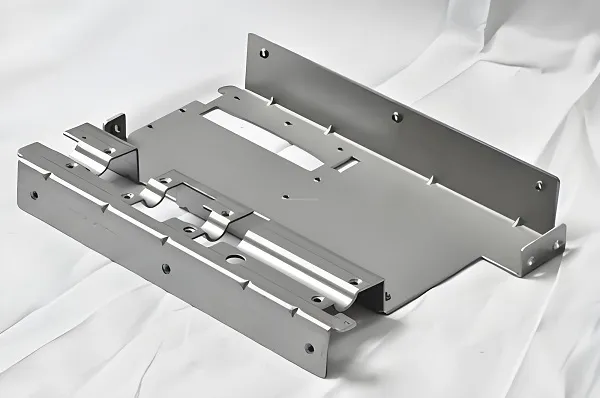

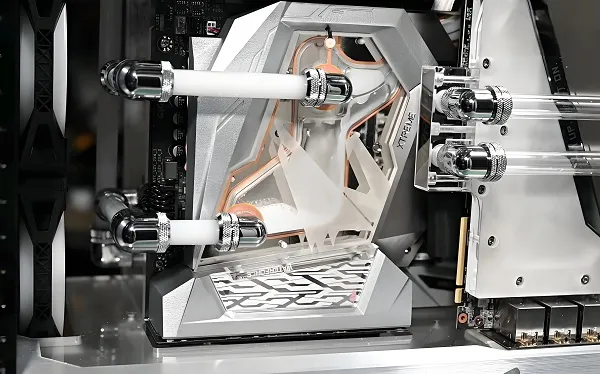

Injection molding: Silicone molds are suitable for injection molding of various plastic products, such as cell phone shells, toys, home appliances and so on.

Vacuum Suction Molding: In the vacuum suction molding process, silicone molds can provide uniform suction to ensure the accuracy of product shape and size.

3D Printing: Silicone molds can be used as an auxiliary tool for 3D printing to support and fix the printing material to improve the printing accuracy and stability.

Other applications: Silicone molds can also be used to make food molds, art molds, etc. to meet diversified needs.

Maintenance and care of silicone molds

Regular cleaning: Use a soft cloth or special cleaner to clean the mold, remove surface stains and residues.

Avoid scratches: During operation, avoid using sharp tools or hard objects to touch the surface of the mold to avoid scratches.

Storage environment: Store the silicone molds in a dry, ventilated, light-proof environment, avoiding prolonged exposure to high temperatures or humid environments.

Regular inspection: Regularly check the silicone mold, if found deformation, cracking and other problems, should be replaced or repaired in a timely manner.

Conclusion

Silicone plastic mold with its unique material properties and superb manufacturing process, in a number of fields to show a wide range of application prospects. We believe that with the continuous progress of technology and the continuous development of the market, silicone mold will play a greater role in more fields. If you are interested in silicone mold or have any questions, please feel free to contact us, we will be happy to serve you.