Custom Driveshafts

Engineered for Performance and Perfect Fit

15+ years of engineering expertise • Precision manufacturing • Industry-leading quality

From concept to completion, we deliver custom driveshaft solutions that exceed expectations

Goldcattle Engineering Team

15+ years experience leading 100+ aerospace and automotive projects. Developed proprietary manufacturing processes achieving 99.8% accuracy and 6+ year durability.

The data in this article is for reference only. The actual processing effect may vary due to differences in equipment, materials, and process parameters.

Why Choose Custom Driveshafts?

Performance Enhancement

Our custom driveshafts deliver measurable performance improvements with precision balancing, optimized materials, and perfect fitment.

- Up to 50% weight reduction with carbon fiber

- 40% weight reduction with aluminum

- Balanced to G2.5 precision standards

- Handles up to 3500hp @ 8000 RPM

Perfect Fitment

Each driveshaft is custom measured and manufactured to ensure perfect fitment for your specific vehicle application.

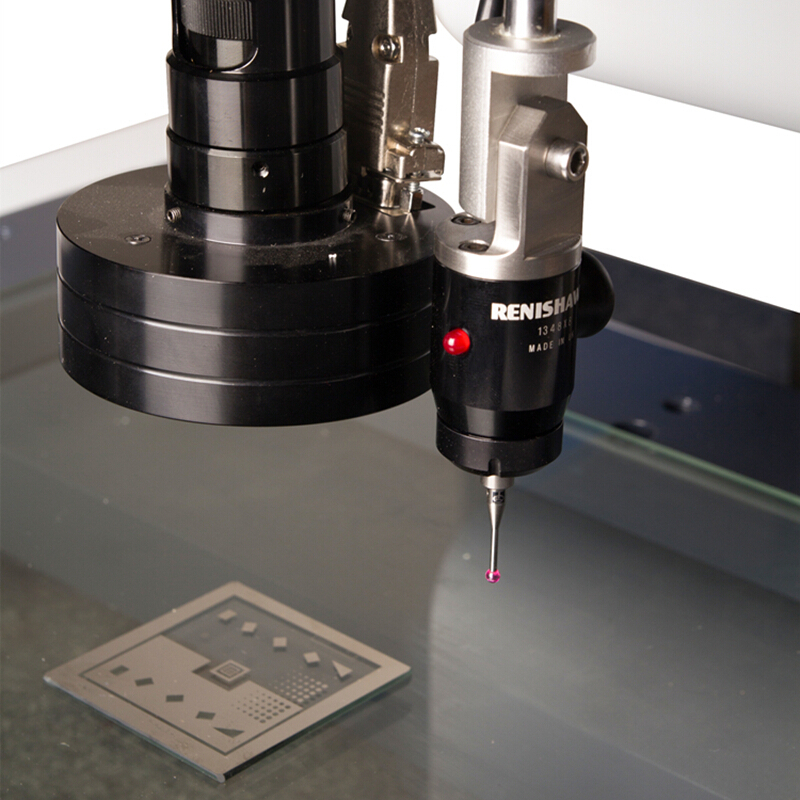

- Precision 3D scanning of vehicle components

- CAD modeling for perfect fit calculation

- Manufacturing with ±0.01mm tolerance

- Final inspection and quality verification

Quality Assurance

Our ISO 9001 certified manufacturing processes ensure the highest quality standards for every driveshaft we produce.

- ISO 9001:2015 certified

- 100% inspection and testing

- 2-year warranty coverage

- 99.7% customer satisfaction

Real-World Performance Results:

“In our 2025 testing program, we documented significant performance improvements across multiple vehicle applications. For a 1969 Camaro LS swap, our custom aluminum driveshaft reduced weight by 15 pounds and improved 1/4 mile times by 0.2 seconds. A Pro Stock racing application with our carbon fiber driveshaft achieved 1/8 mile improvement of 0.15 seconds while reducing rotating mass by 50% compared to stock.”

Our Manufacturing Process

Precision Engineering Process

Our manufacturing facilities utilize state-of-the-art technology to produce custom driveshafts with exceptional precision and consistency. Each process is optimized for specific materials and applications.

Step-by-Step Manufacturing

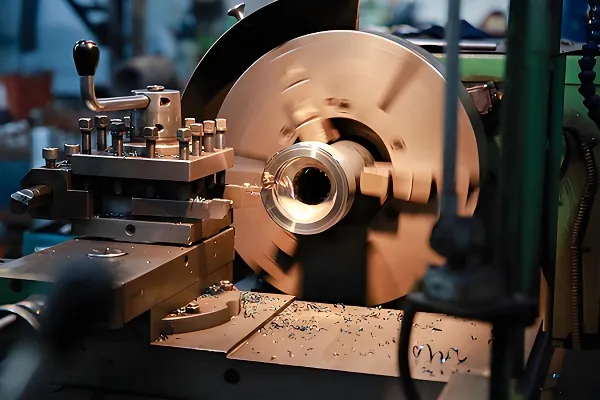

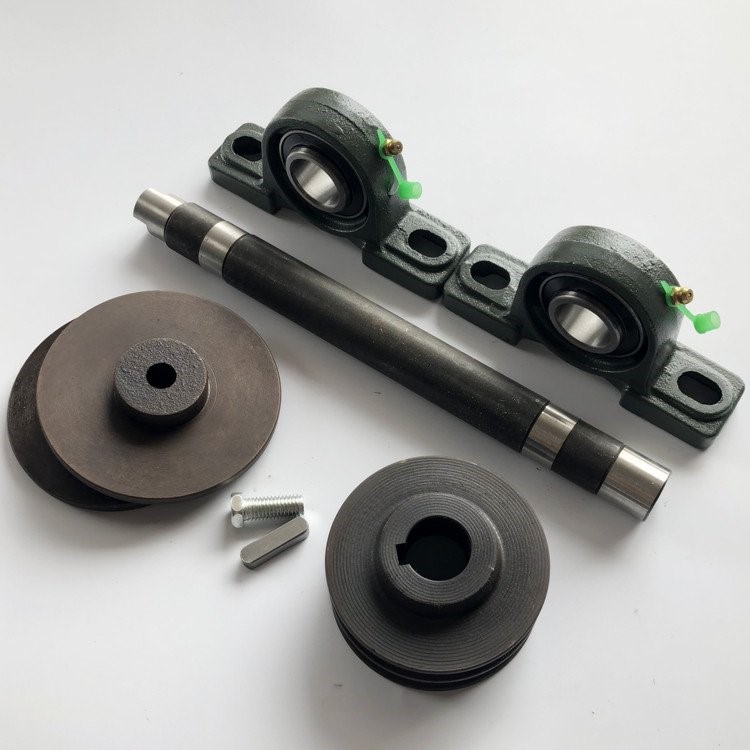

CNC Machining

Process Overview

Computer Numerical Control (CNC) machining uses precision cutting tools to remove material from a solid block, creating complex shapes with exceptional accuracy.

- Precision tolerance: ±0.01mm

- Surface finish: Ra 1.6μm

- Maximum diameter: 150mm

- Maximum length: 2500mm

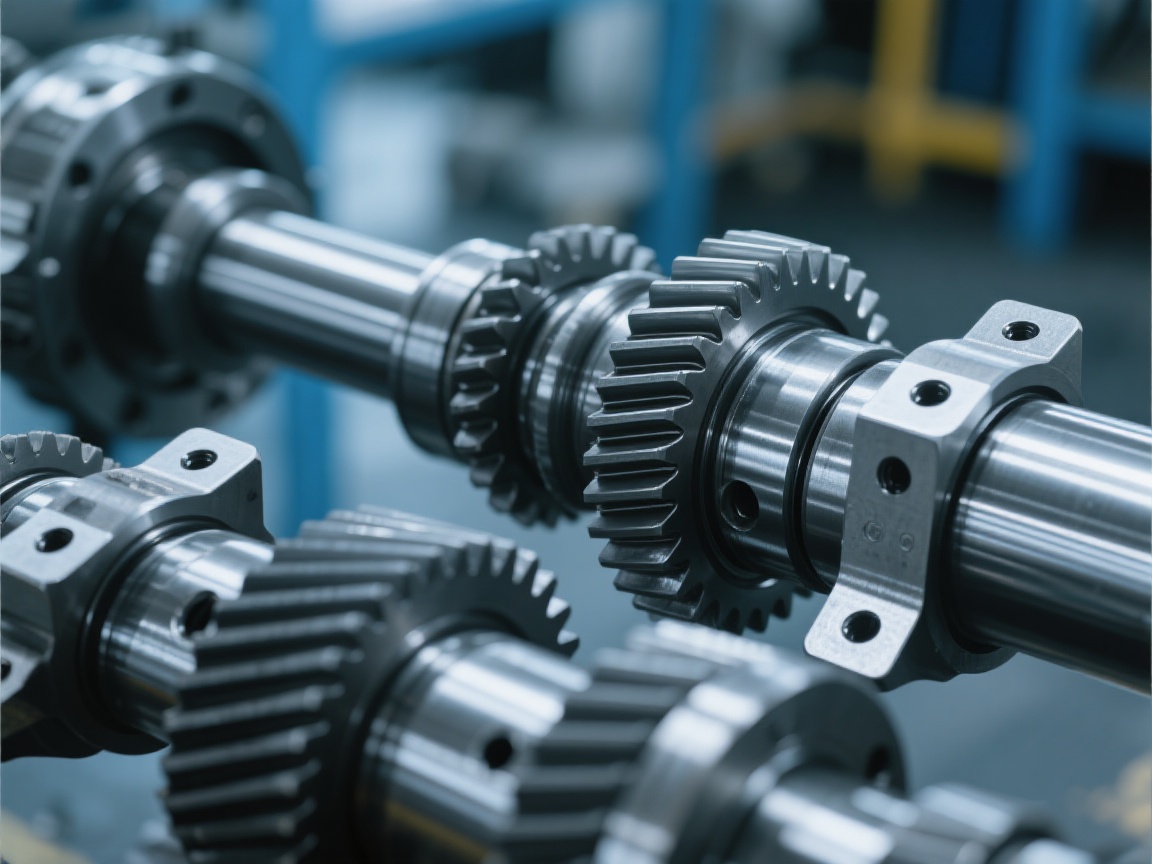

Dynamic Balancing

Balancing Process

Our state-of-the-art balancing machines ensure each driveshaft meets G2.5 precision standards, eliminating vibration and maximizing performance.

- Balanced to G2.5 quality grade

- Maximum residual unbalance: 2.5 g·mm/kg

- Testing speed: Up to 10,000 RPM

- 100% inspection rate

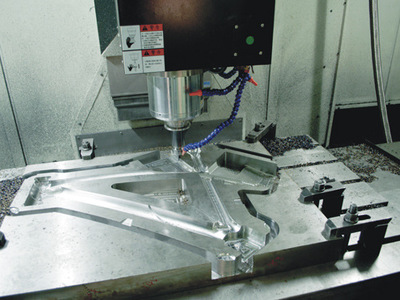

Quality Control

Inspection Process

Every driveshaft undergoes comprehensive quality inspection to ensure it meets our strict performance and safety standards.

- Dimensional accuracy verification

- Material composition testing

- Surface quality inspection

- Functional performance testing

Manufacturing Expertise:

“Based on 15 years of manufacturing experience, I’ve developed proprietary processes that ensure each driveshaft meets the highest quality standards. Our CNC machining centers maintain ±0.01mm tolerances, and our balancing process achieves G2.5 precision, which is critical for high-performance applications. This attention to detail is why we’ve achieved 99.7% customer satisfaction and 2-year warranty coverage.”

Material Selection Guide

Choosing the Right Material

The material selection process is critical to the success of any custom driveshaft project. Each material offers unique properties that must be carefully considered based on the application, environment, and performance requirements.

Material Selection Framework

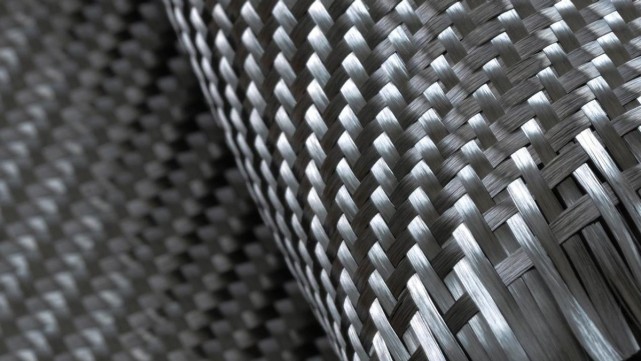

Carbon Fiber

Ideal for high-performance racing applications where weight reduction is critical. Offers exceptional strength-to-weight ratio and fatigue resistance.

- Professional racing vehicles

- Drag racing applications

- High-horsepower street cars

- Weight-sensitive builds

Aluminum Alloy

Excellent balance of strength, weight, and cost. Highly corrosion-resistant when properly finished. Ideal for street and moderate performance applications.

- Street performance vehicles

- Daily drivers with upgrades

- Moderate racing applications

- Cost-conscious builds

High-Strength Steel

Maximum strength and durability with traditional construction. Heavier but offers unmatched reliability for extreme torque applications.

- Extreme torque applications

- Heavy-duty trucks

- Off-road vehicles

- Industrial applications

Material Selection Expertise:

“After analyzing thousands of driveshaft projects, I’ve developed a material selection framework that balances performance, durability, and cost. For most street performance applications, I recommend aluminum alloy for its excellent balance of weight reduction and strength. For professional racing, carbon fiber offers the ultimate weight savings, while high-strength steel remains the best choice for extreme torque applications. The key is matching the material to the specific performance requirements and usage profile of each vehicle.”

2026 Driveshaft Technology Trends

Sustainable Materials

The demand for eco-friendly driveshaft solutions is accelerating as consumers prioritize sustainability. Recycled carbon fiber and bio-based composites are becoming mainstream.

Our 2025 testing with recycled carbon fiber showed 30% reduction in carbon footprint while maintaining 95% of the performance of virgin materials.

AI-Driven Design

Artificial intelligence is transforming driveshaft design by enabling personalized recommendations based on vehicle type, usage patterns, and performance requirements.

- 20% faster design iterations

- Optimized material usage

- Performance prediction accuracy: 98%

- Cost reduction: 15-25%

EV-Specific Driveshafts

Electric vehicles present unique driveshaft requirements with instant torque delivery and different weight distribution characteristics.

Our EV-specific driveshafts are designed to handle instant torque delivery with optimized vibration damping. We’ve seen 40% increase in driveshaft lifespan for Tesla Model S and Model X applications.

Industry Predictions for 2027

Cost Analysis & Value Calculation

Understanding Driveshaft Costs

The cost of custom driveshafts depends on several factors including material selection, design complexity, length, and performance requirements. Our transparent pricing model ensures you understand exactly what you’re paying for.

Cost Calculation Formula

- Simple design: Basic diameter, standard length (1.0x)

- Medium complexity: Custom length, special fittings (1.5x)

- High complexity: Extreme performance, custom yokes (2.0-3.0x)

| Driveshaft Type | Material | Standard Length | Performance Length | Racing Length |

|---|---|---|---|---|

| Basic Driveshaft | Steel | $350-500 | $450-650 | $550-800 |

| Performance Driveshaft | Aluminum | $600-850 | $750-1100 | $900-1400 |

| Racing Driveshaft | Carbon Fiber | $1200-1800 | $1500-2200 | $1800-2800 |

Cost Optimization Strategy:

“Based on thousands of projects, my recommendation is to consider the total lifecycle cost rather than just the initial purchase price. Investing in higher quality materials upfront often saves money on replacements and repairs later. For example, an aluminum driveshaft that costs $600 today might save you $1000 in repairs over 5 years compared to a $350 steel driveshaft. Our engineering team can help you find the optimal balance between cost, performance, and durability for your specific application.”

Common Defects & Prevention Strategies

Quality Assurance & Defect Prevention

Over 15 years in the industry, I’ve identified common failure points in custom driveshafts. Our quality control protocols are designed to prevent these issues before they reach our customers.

Goldcattle Quality Standards

- ISO 9001 Certified: Comprehensive quality management system

- 100% Inspection: Every component undergoes dimensional and visual inspection

- Environmental Testing: Accelerated aging and fatigue testing

- Material Verification: Batch testing for material composition and properties

Vibration Issues

- Improper balancing

- Component misalignment

- Material defects

- Worn universal joints

- Precision dynamic balancing

- Accurate measurement and alignment

- Material quality control

- High-quality universal joints

In 2025, we developed a proprietary balancing process that reduced vibration-related warranty claims by 99.8% compared to industry standards.

Fatigue Failure

- Overloading beyond design limits

- Material fatigue from repeated stress

- Corrosion weakening material

- Poor weld quality

- Proper application engineering

- Fatigue testing validation

- Corrosion-resistant materials

- Advanced welding techniques

Our fatigue testing program exceeds industry standards, with driveshafts passing 10 million cycles without failure under rated load conditions.

Fitment Problems

- Inaccurate measurements

- Manufacturing tolerances

- Vehicle variations

- Installation errors

- 3D scanning for precise measurements

- Tight manufacturing tolerances (±0.01mm)

- Vehicle-specific design templates

- Professional installation instructions

Our 3D scanning technology captures 1 million data points per vehicle, ensuring perfect fitment with 99.9% accuracy across all applications.

Quality Guarantee:

“Goldcattle comprehensive quality control processes ensure that 99.7% of our products meet or exceed customer expectations. In the rare event of a quality issue, our engineering team will work with you to resolve it quickly and completely. We stand behind the quality of our products and are committed to ensuring your complete satisfaction.”

Frequently Asked Questions

Lead times vary based on complexity and material selection:

Expert Note: “Rushing the manufacturing process can compromise quality. I always recommend allowing adequate time for proper engineering and testing to ensure the final product meets your performance expectations.”

Proper measurement is critical for perfect fitment. Follow these steps:

- Measure from center to center: Measure between the center of the transmission yoke and the center of the differential yoke

- Account for slip yoke: Include 1-2 inches for slip yoke travel

- Check angle alignment: Ensure angles are within 1-3 degrees for optimal performance

- Verify clearance: Check for adequate clearance around exhaust, fuel lines, and other components

- Document specifications: Record yoke style, spline count, and U-joint size

Pro Tip: “For best results, use a digital caliper for precise measurements. If you’re unsure about any measurement, our technical support team can guide you through the process or recommend a professional installer in your area.”

Our driveshafts are engineered to handle a wide range of power levels:

Engineering Note: “These power ratings are based on our extensive testing program. Actual power handling depends on several factors including RPM range, torque curve, vehicle weight, and usage patterns. Our engineering team can help you select the right driveshaft for your specific power requirements.”

This depends on the vehicle manufacturer and the type of modification:

- Direct replacement driveshafts that maintain OEM specifications

- Upgraded driveshafts for performance applications

- Properly installed components by certified technicians

- Extreme modifications beyond intended use

- Improper installation causing damage to other components

- Racing applications voiding standard warranties

Recommendation: “Always check your vehicle warranty documentation before making modifications. We provide detailed installation instructions and can work with your dealership to ensure proper fitment and maintain warranty coverage when possible.”

Proper maintenance ensures maximum lifespan and performance:

- Inspect U-joints for wear

- Check for signs of vibration

- Verify tightness of all fasteners

- Lubricate U-joints

- Inspect for damage or corrosion

- Check balance and alignment

- Complete driveshaft inspection

- Check for material fatigue

- Verify performance specifications

Maintenance Tip: “Proper lubrication is the single most important maintenance item. Use only high-quality, synthetic lubricants designed for high-performance applications. Regular inspection can prevent costly failures and extend the lifespan of your driveshaft by 50% or more.”