1. Core Technical Functions of Aluminium Milling Spindles

(1) High-Speed Cutting Adaptation: Reducing BUE and Improving Efficiency

- Wide Speed Range: Typical rated speed of 10,000–40,000 rpm (vs. 5,000–15,000 rpm for steel milling spindles). For 6061 aluminium fine milling, speeds of 20,000–30,000 rpm reduce BUE by 90% and boost material removal rate (MRR) to 500–1000 cm³/min.

- High Dynamic Balance: Achieves G0.4 dynamic balance grade (per ISO 1940-1) at maximum speed—vibration amplitude ≤0.1 mm/s. This avoids tool chatter (a major cause of uneven aluminium surfaces) and ensures consistent cutting force (fluctuation ≤5%).

- High Torque at High Speeds: Equipped with a high-frequency motor (400 Hz or 600 Hz) to maintain torque at high speeds—e.g., a 15 kW spindle delivers ≥20 N·m at 20,000 rpm (sufficient for 7075 aluminium roughing with 10 mm depth of cut).

(2) Efficient Heat Dissipation: Preventing Thermal Deformation

- Spindle taper thermal expansion (0.002–0.005 mm at 80°C), leading to tool runout;

- Workpiece thermal warpage (especially thin-walled aluminium parts, thickness ≤2 mm).

- Dual-Circuit Cooling System: Water-cooled jacket (flow rate 20–30 L/min, inlet temperature 20–25°C) for the motor stator + oil-mist lubrication (3–5 mL/h) for bearings. This controls spindle surface temperature rise to ≤20°C (ambient temperature 25°C).

- Thermal Symmetry Design: Spindle housing made of aluminium alloy (6061-T6) with uniform wall thickness (15–20 mm) to ensure even heat distribution—thermal expansion difference between upper and lower housing ≤0.001 mm.

(3) Anti-Adhesion & Chip Protection: Extending Spindle Life

- Taper wear (reducing tool positioning accuracy);

- Bearing seizure (due to chip contamination).

- Air Curtain System: 0.5–0.8 MPa compressed air is injected from the spindle front end (around the taper) to form an air barrier—blocks 98% of aluminium chips from entering the taper and bearing chamber.

- Taper Coating: Spindle taper (HSK-A63 or CAT 50) coated with TiAlN (thickness 3–5 μm, hardness HRC 80)—reduces aluminium adhesion by 80% and improves taper wear resistance (service life extended by 2x).

- Labyrinth Seals: Bearing chamber sealed with labyrinth structures (gap ≤0.1 mm) + oil seal (nitrile rubber, Shore hardness 70±5A) to prevent chip-laden coolant from infiltrating.

(4) Rigid Dynamic Performance: Ensuring Machining Precision

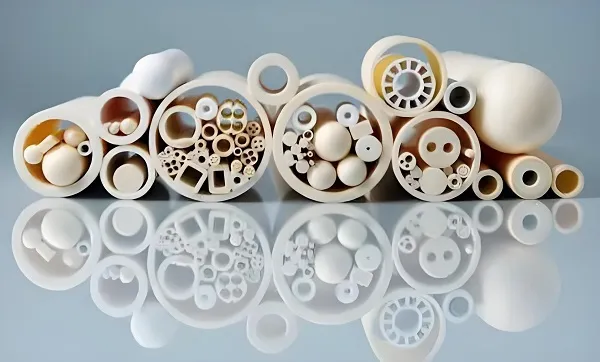

- High-Stiffness Bearings: Uses ceramic hybrid bearings (steel outer ring + Si₃N₄ ceramic balls) with preload adjustment—radial stiffness ≥500 N/μm (vs. 300 N/μm for all-steel bearings). For thin-walled aluminium milling (thickness 1 mm), this reduces workpiece deformation to ≤0.003 mm.

- Short Overhang Design: Spindle front overhang (distance from front bearing to tool tip) ≤80 mm (vs. 100–120 mm for general spindles)—reduces spindle deflection under cutting force (deflection ≤0.001 mm at 5 kN force).

2. Technical Classification of Aluminium Milling Spindles

(1) Classification by Drive Type

|

Drive Type

|

Design Features

|

Applicable Aluminium Machining Scenarios

|

Key Parameters

|

|

Electric Spindle

|

Integrates motor and spindle (no belt/pulley); compact structure.

|

High-speed fine milling (e.g., 7075 aluminium aerospace parts, 20,000–30,000 rpm); micro-milling (e.g., aluminium phone frames, φ0.5–2 mm tools).

|

Power: 5–30 kW; Speed: 10,000–40,000 rpm; Runout: ≤0.001 mm

|

|

Mechanical Spindle

|

Motor drives spindle via belt/pulley; cost-effective.

|

Low-speed heavy-duty roughing (e.g., 6061 aluminium structural parts, 5,000–15,000 rpm); large aluminium castings (weight ≥50 kg).

|

Power: 15–45 kW; Speed: 5,000–20,000 rpm; Torque: ≥80 N·m (at 5,000 rpm)

|

|

Hybrid Spindle

|

Combines electric spindle high speed and mechanical spindle high torque; dual-mode drive.

|

Mixed processes (roughing + finishing) on one machine (e.g., aluminium wheel hubs: roughing at 8,000 rpm, finishing at 20,000 rpm).

|

Speed range: 3,000–30,000 rpm; Torque: ≥50 N·m (at 10,000 rpm)

|

(2) Classification by Cooling Method

|

Cooling Method

|

Composition

|

Advantages

|

Limitations

|

|

Water-Cooled Spindle

|

Water jacket around motor stator; coolant flow rate 20–30 L/min.

|

High cooling efficiency (removes 80% of motor heat); suitable for high-power spindles (15–30 kW).

|

Requires water chiller (maintains coolant temp ±1°C); risk of corrosion if coolant is unfiltered.

|

|

Oil-Cooled Spindle

|

Oil circulation through motor and bearings; oil viscosity 32–46 cSt.

|

Better temperature control (±0.5°C); no corrosion risk.

|

Higher cost (2x water-cooled); oil replacement every 6 months.

|

|

Air-Cooled Spindle

|

Fans + heat sinks on spindle housing; airflow 500–800 m³/h.

|

No coolant system; lightweight (suitable for mobile mills).

|

Low cooling capacity (only for small spindles ≤5 kW); speed limited to ≤20,000 rpm.

|

3. Key Design Parameters for Aluminium Milling Spindles

(1) Speed & Torque Matching

- Rated Speed: Select based on aluminium alloy and tool size:

-

- 6061/5052 aluminium (soft): 15,000–30,000 rpm (for φ5–12 mm carbide end mills);

-

- 7075 aluminium (harder): 10,000–25,000 rpm (for φ8–16 mm tools);

-

- Micro-milling (φ0.5–2 mm tools): 30,000–40,000 rpm (avoids tool breakage).

- Torque Requirement: Roughing requires high torque (e.g., 7075 aluminium roughing with 10 mm depth of cut needs ≥30 N·m at 10,000 rpm); finishing needs low torque but high speed (≥10 N·m at 25,000 rpm).

(2) Precision & Rigidity Parameters

- Radial Runout: ≤0.001 mm at the tool taper (HSK-A63) — critical for aluminium surface roughness (Ra ≤0.4 μm).

- Axial Runout: ≤0.0005 mm — ensures consistent depth of cut (e.g., 0.1 mm finishing pass accuracy ±0.001 mm).

- Static Stiffness: Radial stiffness ≥400 N/μm, axial stiffness ≥600 N/μm — reduces deflection when milling thin-walled aluminium (thickness 1–2 mm).

(3) Cooling & Protection Parameters

- Coolant Temperature Control: Inlet temperature 20–25°C, temperature fluctuation ≤±1°C — prevents spindle thermal expansion (≤0.002 mm).

- Air Curtain Pressure: 0.5–0.8 MPa — ensures chip protection without interfering with coolant delivery (coolant pressure 0.3–0.5 MPa).

- IP Rating: ≥IP54 (per IEC 60529) — resists coolant splashes and aluminium dust (common in dry milling of aluminium).

(4) Tool Interface Compatibility

- Taper Type: HSK-A (HSK-A50/A63) for high-speed spindles (15,000–40,000 rpm) — better concentricity than CAT/BT tapers; BT40/BT50 for mechanical spindles (low-speed heavy-duty).

- Tool Clamping Force: ≥15 kN (for HSK-A63) — prevents tool pull-out during high-speed aluminium milling (centrifugal force ≥10 kN at 30,000 rpm).

4. Adaptation Design for Different Aluminium Milling Scenarios

(1) Aerospace Thin-Walled Aluminium Parts (e.g., 7075 Aluminium Frame, Thickness 1–3 mm)

- Key Requirement: Ultra-low vibration (to avoid deformation) and high precision.

- Spindle Selection: Water-cooled electric spindle (10–15 kW, 20,000–30,000 rpm); ceramic hybrid bearings (radial stiffness ≥500 N/μm); G0.4 dynamic balance.

- Design Optimization: Short front overhang (≤60 mm) + air curtain (0.6 MPa) — reduces deflection to ≤0.001 mm and prevents chip adhesion.

- Example: For a Boeing 787 aluminium rib (thickness 1.5 mm), the spindle achieves Ra 0.3 μm and dimensional tolerance ±0.003 mm.

(2) Automotive Large Aluminium Components (e.g., 6061 Aluminium Wheel Hub, Diameter 600–800 mm)

- Key Requirement: High torque for roughing + high speed for finishing.

- Spindle Selection: Hybrid spindle (20–25 kW, 5,000–25,000 rpm); oil-cooled (temperature control ±0.5°C); BT50 taper (high clamping force ≥20 kN).

- Design Optimization: Variable-speed motor (400/600 Hz dual-frequency) — delivers 80 N·m at 8,000 rpm (roughing) and 15 N·m at 25,000 rpm (finishing).

- Example: Reduces wheel hub machining time from 60 min (mechanical spindle) to 40 min (hybrid spindle).

(3) Electronic Micro-Aluminium Parts (e.g., 5052 Aluminium Phone Middle Frame, φ0.5–2 mm Features)

- Key Requirement: Ultra-high speed (for micro-tools) and precise tool positioning.

- Spindle Selection: Air-cooled electric spindle (3–5 kW, 30,000–40,000 rpm); HSK-A50 taper (runout ≤0.0008 mm); integrated tool length sensor (accuracy ±0.0005 mm).

- Design Optimization: Miniature bearing design (7004C ceramic hybrid bearings) — allows high speed without overheating; vacuum chip suction (connected to spindle rear) — removes micro-chips (≤0.1 mm) to avoid tool clogging.

- Example: Machines 0.8 mm diameter holes in phone frames with position accuracy ±0.002 mm.

5. Installation, Maintenance, and Troubleshooting

(1) Installation Precautions

- Concentricity Alignment: Align spindle taper with the machine’s Z-axis (parallelism ≤0.001 mm/m) — misalignment causes tool runout (≥0.003 mm) and aluminium surface scratches.

- Coolant System Flushing: Before connecting the spindle, flush the cooling circuit with distilled water (for water-cooled) or clean oil (for oil-cooled) — removes debris that causes blockages.

- Air Curtain Calibration: Adjust air pressure to 0.6 MPa (use a pressure gauge) — too low (≤0.3 MPa) fails to block chips; too high (≥1 MPa) disturbs coolant flow.

(2) Routine Maintenance

|

Maintenance Item

|

Frequency

|

Operation Details

|

|

Bearing Lubrication

|

Every 6 months

|

For oil-mist lubrication: Replace oil (ISO VG 32) and clean mist generator; check oil flow (3 mL/h).

|

|

Taper Cleaning

|

After 50 tool changes

|

Wipe taper with isopropyl alcohol (avoid abrasive cloth); inspect for aluminium adhesion (use a magnifying glass, 10×).

|

|

Cooling System Check

|

Weekly

|

For water-cooled: Check coolant pH (7–8) and conductivity (≤50 μS/cm); clean filter (5 μm mesh).

|

|

Dynamic Balance Verification

|

Annual

|

Use a dynamic balance tester to recheck balance grade (ensure G0.4 at max speed); add counterweights if needed.

|

(3) Common Issues and Solutions

|

Common Issue

|

Cause

|

Solution

|

|

Spindle Speed Fails to Reach 20,000 rpm

|

Cooling system blocked (flow rate <15 L/min); motor inverter overheating.

|

Clean cooling circuit with 5% citric acid solution; replace inverter fan (if temperature >60°C).

|

|

Aluminium Chips Stuck in Taper

|

Air curtain pressure too low (<0.5 MPa); taper coating worn (TiAlN thickness <2 μm).

|

Increase air pressure to 0.6–0.8 MPa; re-coat taper with TiAlN (3 μm).

|

|

Tool Runout >0.003 mm

|

Bearing preload reduced (due to wear); taper contamination.

|

Adjust bearing preload (add 0.002 mm shim); clean taper with acetone and recheck runout.

|

|

Spindle Noise >75 dB

|

Bearing damage (metal-to-metal contact); coolant leaking into bearings.

|

Replace ceramic hybrid bearings; replace labyrinth seals and check air curtain.

|

6. Future Trends in Aluminium Milling Spindle Technology

(1) Intelligent Condition Monitoring

- Sensor Integration: Embed temperature (accuracy ±0.1°C), vibration (resolution 0.01 mm/s), and torque (resolution 0.1 N·m) sensors in the spindle — real-time data transmitted to the CNC system (e.g., Fanuc 31i-B) to alert operators of anomalies (e.g., bearing temperature >70°C).

- AI-Powered Predictive Maintenance: Use machine learning to analyze 10,000+ hours of operating data — predict bearing life (accuracy ≥90%) and recommend maintenance before failures.

(2) Higher Speed and Precision

- Ultra-High Speed Spindles: 50,000–60,000 rpm electric spindles (using magnetic bearings) — suitable for micro-milling of aluminium microstructures (e.g., φ0.1 mm grooves in semiconductor substrates).

- Nanoscale Precision: Radial runout ≤0.0005 mm (via precision grinding of spindle tapers) — enables aluminium optical components (surface roughness Ra ≤0.02 μm).

(3) Eco-Friendly and Energy-Saving

- Energy-Efficient Motors: Permanent magnet synchronous motors (PMSM) — reduce energy consumption by 20% compared to induction motors (e.g., a 15 kW PMSM spindle uses 3 kWh less per 8-hour shift).

- Dry Milling Adaptation: Integrate high-efficiency air-cooling (airflow 1,000 m³/h) and vacuum chip suction — eliminates coolant waste (saves 100–200 L of coolant per month) for dry aluminium milling.