Stainless Steel CNC Turning Parts – Precision Machining Services | Xiamen Goldcattle (26 Years Expertise)

In aerospace, medical devices, and high-end equipment, stainless steel parts (304, 316L, 17-4PH) are the top choice for key structural components. Xiamen Goldcattle’s stainless steel CNC turning service achieves ±0.01mm tolerance, Ra≤1.6μm surface finish, and 50%+ efficiency improvement.

Precision stainless steel CNC turning parts with Ra≤1.6μm surface finish

Stainless Steel Grades Quick Comparison

Choosing the right stainless steel grade is critical for your application. Here’s how the most common grades compare:

| Grade | Corrosion Resistance | Strength | Machinability | Typical Applications | Goldcattle Recommendation |

|---|---|---|---|---|---|

| 304 | Good | Medium (HB 150-180) | Easy | Food equipment, chemical tanks | General purpose, cost-effective |

| 316L | Excellent | Medium (HB 140-170) | Medium | Medical devices, marine parts | High corrosion resistance needs |

| 17-4PH | Good | High (HB 300-400) | Difficult | Aerospace, high-strength parts | High strength, precision critical |

| 2205 | Superior | Very High (HB 270-320) | Very Difficult | Oil & gas, chemical processing | Extreme corrosion environments |

Pro Tip: For medical applications requiring biocompatibility, 316L is our top recommendation. For aerospace with high strength needs, 17-4PH is ideal.

I. Bottlenecks of Traditional Turning: Why is Stainless Steel Processing So Difficult?

“Many customers tell us: stainless steel parts always have burrs, dimension drift, and frequent tool changes after turning—these are common pitfalls of traditional processes.”

Core Difficulties in Stainless Steel CNC Turning

The unique properties of stainless steel materials (high hardness HB 150-200, high plasticity, and easy work-hardening) lead to three major pain points:

- Severe tool wear: Ordinary carbide tools stick to material, generating built-up edges. Tool life is only 3-5 hours, requiring frequent changes.

- Uncontrolled thermal deformation: Concentrated cutting heat (800℃ locally) causes workpiece expansion. Traditional cooling can’t dissipate heat quickly, leading to ±0.15mm errors.

- Surface quality defects: Stainless steel is highly viscous. Conventional turning produces scratches, burrs, and vibration marks with Ra 6.3μm, needing additional polishing.

Breakthrough Paths

- • Hardware upgrade: High-precision CNC lathes with dynamic vibration-damping systems

- • Process innovation: Cutting parameter optimization and intelligent cooling

- • Tool technology: Advanced CBN and coated carbide tools

Traditional turning (left) vs precision CNC turning (right) surface finish comparison

Goldcattle Experience

“We once had a batch of 316L medical parts requiring Ra<1.0μm. Traditional methods failed three times—we solved it with CBN tools + cryogenic MQL, passing inspection on the first try.”

II. Core Process Innovations: How to Achieve Precision Turning of Stainless Steel?

Breakthroughs in Special-Purpose Tool Technology

Tool Material Upgrade

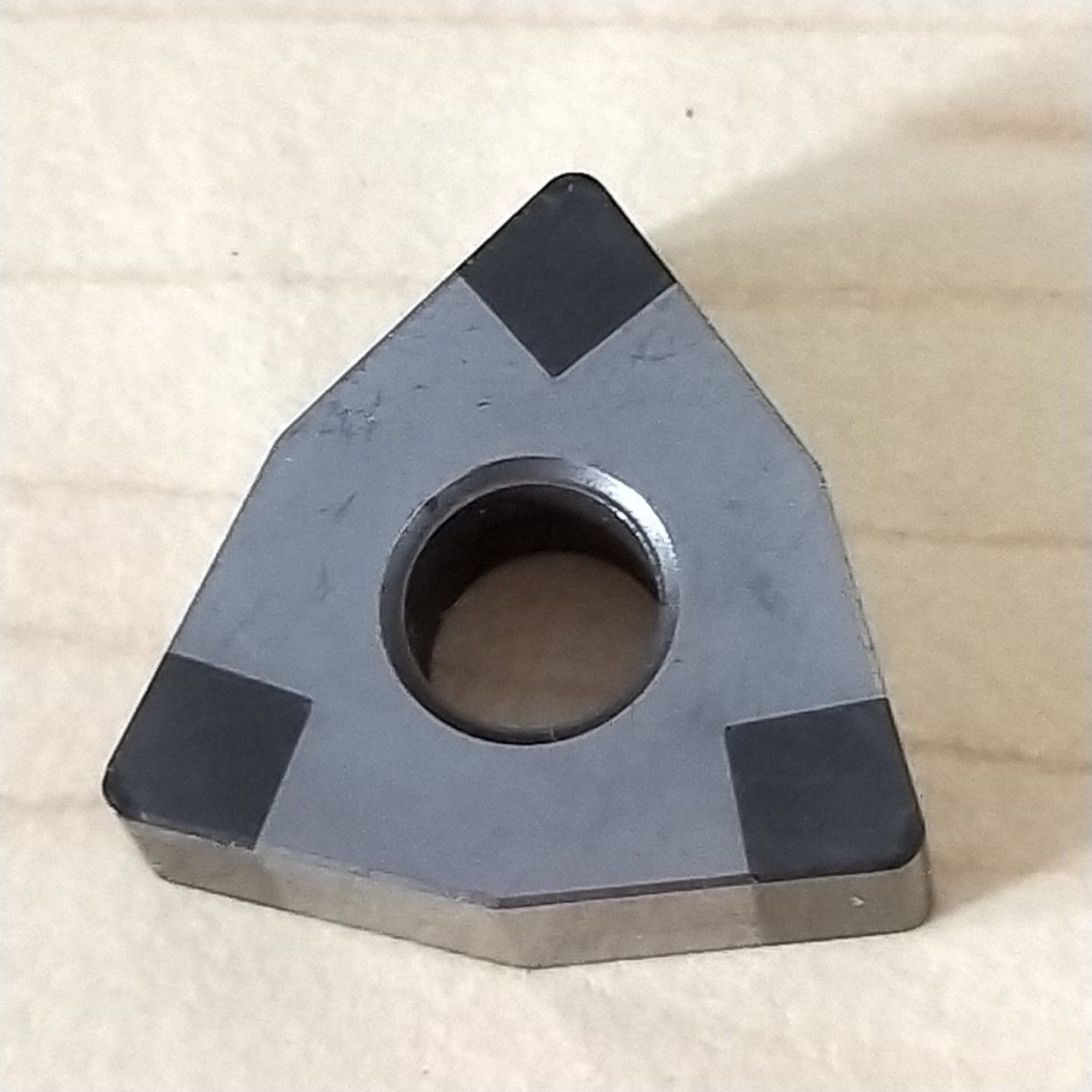

CBN (Cubic Boron Nitride) Tools

Hardness HV3000, suitable for high-hardness stainless steel (17-4PH). Cutting speed up to 150m/min, tool life extended to 15+ hours.

Coated Carbide Tools

TiAlN coating (2-3μm thickness) reduces friction coefficient, tool wear reduced by 40%. Suitable for 304/316L.

CBN cutting tools for high-performance stainless steel turning

Intelligent Cooling and Thermal Management

Cryogenic Minimum Quantity Lubrication (MQL) system for stainless steel turning

Cryogenic MQL Technology

Composite cooling with -20℃ cold air and plant-based cutting fluid (0.1ml/min flow rate) reduces cutting area temperature by 30%, increases tool life by 50%, and reduces surface residual stress by 60%.

Thermal Deformation Compensation

Built-in temperature sensors (±0.5℃ accuracy) real-time correct spindle thermal elongation (0.002mm compensation accuracy), ensuring stable machining accuracy over long periods.

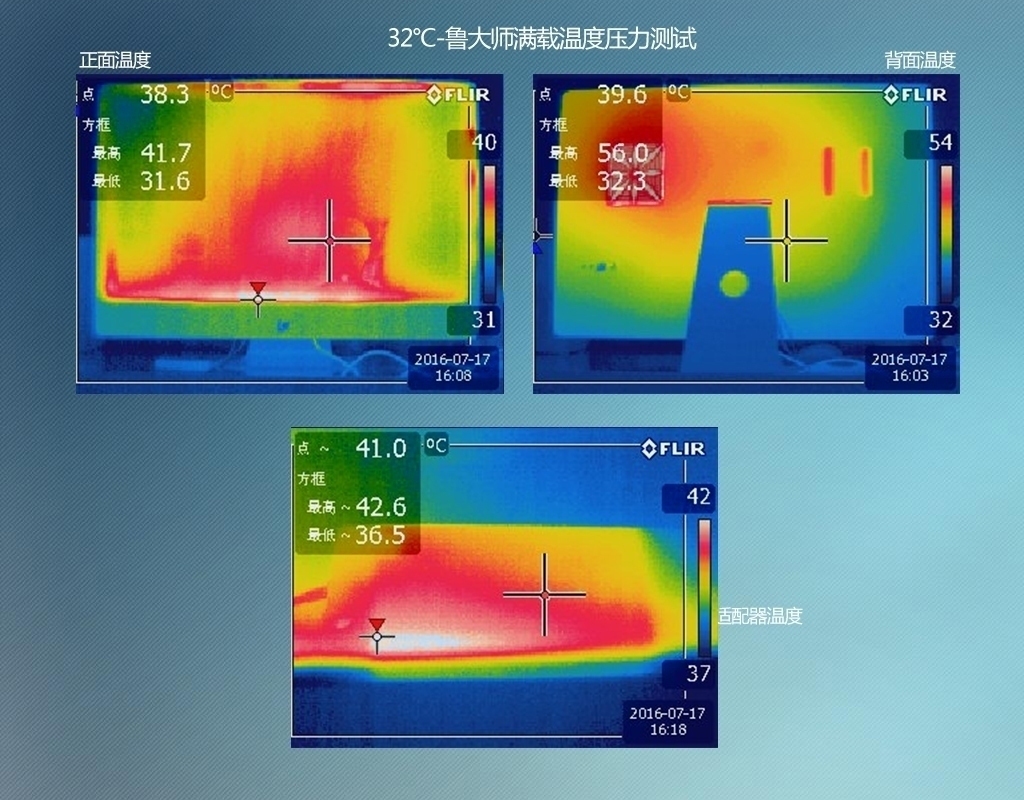

Temperature Control Effectiveness

Traditional Cooling: 800℃

Goldcattle Solution: <200℃

Digital Turning Processes

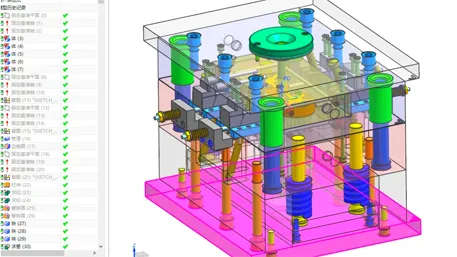

CAM Programming Optimization

MasterCAM software generates spiral feed and layer-by-layer cutting paths, avoiding impact wear from sudden tool entry, increasing processing efficiency by 30%.

Real-time Processing Monitoring

Force-control sensors (±1N accuracy) dynamically monitor cutting force. AI algorithm automatically adjusts feed rate. When load exceeds threshold (>500N), system triggers speed-reduction protection within 0.1 seconds.

AI vision inspection system for real-time quality monitoring

III. Quality Control: Full-Chain Precision Verification

Our quality control system ensures every stainless steel part meets the highest standards, from material incoming to finished product inspection.

Multi-Dimensional Testing System

CMM coordinate measuring machine for precision inspection

Material-level Verification

- • Spectral analysis: Ensures Cr, Ni contents meet ASTM standards (316L: Ni 10.0-14.0%, S≤0.03%)

- • Intergranular corrosion test: ASTM A262 E method verifies corrosion resistance

- • Mechanical testing: Hardness, tensile strength verification

Finished-product Testing

- • Dimensional accuracy: Laser interferometer detects outer/inner diameter tolerance (±0.005mm)

- • Surface quality: Roughness tester (0.01μm resolution) ensures Ra≤1.6μm

- • Functional testing: Hydraulic test bench, dynamic balance machine

Intelligent Defect Prevention

First-piece Eight-inspection System

Engineer team cross-verifies 25 indicators including tool type, cutting parameters, and first piece dimensions, intercepting 99% of initial process risks.

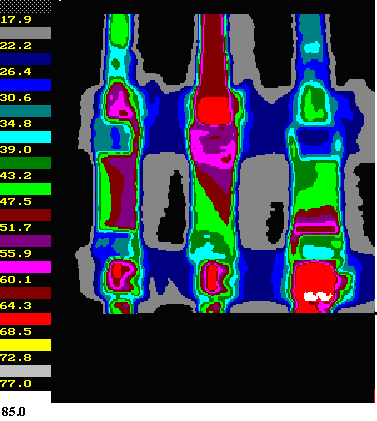

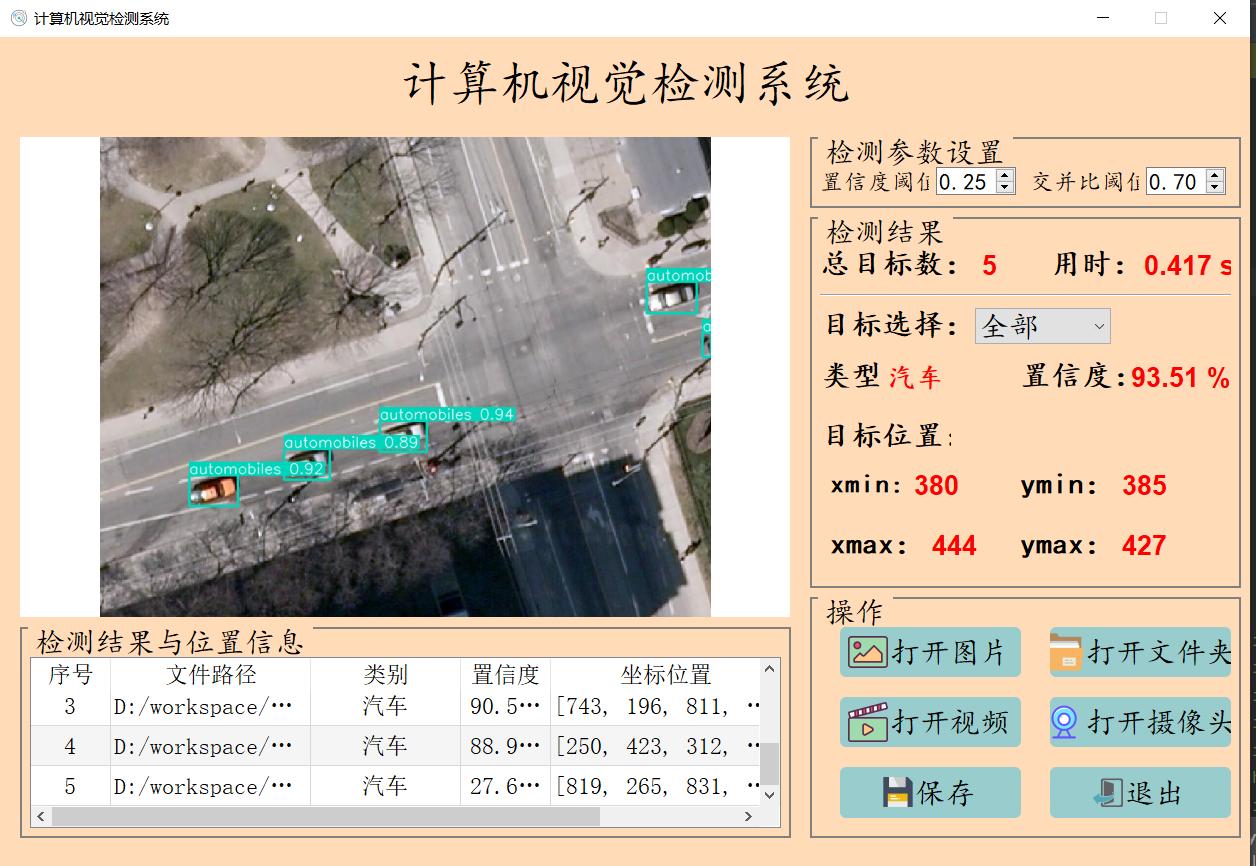

AI Visual Full-inspection

Linear-array camera (12000dpi resolution) completes surface scanning in 0.3 seconds. Deep-learning algorithm identifies 0.05mm level scratches with <0.002% missed-detection rate.

AI visual inspection interface for automated quality control

All reports are traceable to raw material batches, complying with ISO 13485 & AS9100D requirements.

IV. Balancing Efficiency and Cost: Flexible Production from Small-Batch to Large-Batch

Q&A: Does high-precision turning mean high cost?

No—we achieve cost reduction and efficiency improvement through three key innovations:

Three Key Innovations

Tool Life Management

Tool wear prediction model dynamically calculates remaining tool life (error <5%), reducing unplanned tool-change time by 30%.

Process Integration Optimization

Turn-mill compound machine completes outer-circle, inner-hole, and thread processing in one clamping, reducing 3 clamping errors and increasing efficiency by 40%.

Digital Production Scheduling

MES system intelligently matches orders with equipment capacity. Multi-variety small-batch production (50-500 pieces) switching time <30 minutes.

Turn-mill compound machine for integrated processing

MES production management system interface

Goldcattle Success Story

“For a batch of aerospace 17-4PH pins, we used real-time force sensors to monitor cutting forces, preventing micro-cracks caused by sudden force changes. The customer was impressed with our 99.8% first-pass yield.”

V. Core Considerations for Choosing Stainless Steel CNC Turning Services

Choosing the right supplier is critical for your stainless steel turning project success. Here are the key factors to consider:

Equipment & Process Match

Confirm supplier has high-precision CNC lathes (Mazak Integrex i-400AM) and CBN tool experience, can process parts with max diameter ≥300mm.

Industry Certifications

Medical: ISO 13485. Aerospace: AS9100D. Food machinery: FDA or 3A certification.

Data Transparency

Require processing parameter logs and full-size inspection reports (CMM data) to support part full-life-cycle traceability.

ISO 13485 medical device certification

Temperature and humidity controlled workshop

Xiamen Goldcattle Stainless Steel Turning Capabilities

| Capability | Specification | Industry Standard | Goldcattle Advantage |

|---|---|---|---|

| Dimensional Tolerance | ±0.005mm | ±0.01-0.05mm | 5-10x tighter tolerance control |

| Surface Roughness | Ra≤0.8μm | Ra 1.6-6.3μm | Mirror-like finish without polishing |

| Max Diameter | 600mm | 300-400mm | Larger part capability |

| Materials | 304, 316L, 17-4PH, 2205 | Limited to common grades | Expertise in difficult-to-machine grades |

| Inspection Items | CMM, roughness, hardness, corrosion | Basic dimensional checks | Comprehensive quality verification |

Conclusion

For 26 years, Xiamen Goldcattle has treated every stainless steel turning operation as a commitment to precision—from tool selection to full-chain quality control. We help customers turn “difficult stainless steel” into reliable core components.

The stainless steel CNC turning service takes “tool innovation + intelligent cooling + digital control” as core competitiveness, systematically solving efficiency and precision bottlenecks of traditional processing. In the context of increasingly stringent component reliability requirements in high-end manufacturing, turning solutions with “micrometer-level precision, intelligent production, and full-scenario adaptation” are becoming core support in aerospace structural components, medical implants, and food-grade pipeline fittings.

Goldcattle Medical Case Study

“In 2025, we processed 17-4PH bone screws for a medical customer with positional accuracy controlled within 0.005mm. The batch consistency passed strict biocompatibility audits, earning us long-term partnership.”

Ready for Your Stainless Steel Precision Parts?

Upload your CAD drawing for a fast DFM review and quote. Contact us via email/WhatsApp or fill the form below.