Xiamen Goldcattle : 26 Years CNC Manufacturing

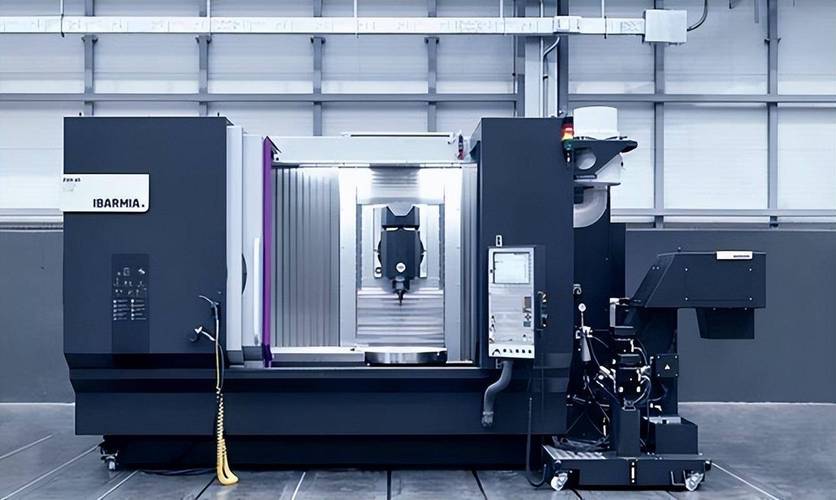

Our Factory – Where Magic Happens 26 Years? That’s Like CNC Royalty! Dude, walking into their workshop is like entering a precision paradise! Rows of shiny CNC machines humming away…

Our Factory – Where Magic Happens 26 Years? That’s Like CNC Royalty! Dude, walking into their workshop is like entering a precision paradise! Rows of shiny CNC machines humming away…

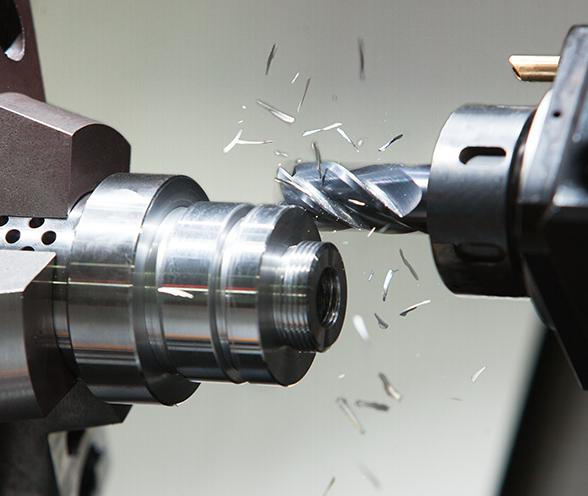

The Most Confused “Brothers” in the Shop: Core Differences Between Drilling and Milling When I first started, I could never tell the difference between drilling and milling—both just sounded like…

1. Core Cognition: What Are Feeds and Speeds, and Why They Matter In CNC drilling, feeds and speeds are the two most critical parameters—their balance determines whether you achieve fast,…

1. Core Cognition: Why CNC Drilling Acrylic Requires Unique Methods Acrylic (polymethyl methacrylate, PMMA) is a thermoplastic with distinct properties that set it apart from metals like aluminum or steel—making…

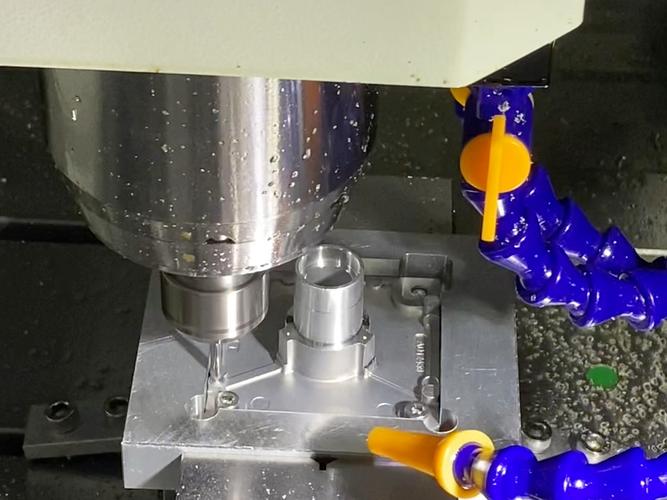

1. Core Cognition: Why CNC Drilling Aluminum Requires Specialized Methods The physical properties of aluminum alloys (e.g., 6061, 7075) differ significantly from those of steel and stainless steel, directly requiring…

Author: Li Gong, CNC Expert, 15+ Years Experience | Last Updated: January 19, 2026 | Based on Goldcattle 2025 Real Project Data Introduction: Understanding CNC Drilling and Milling CNC drilling…

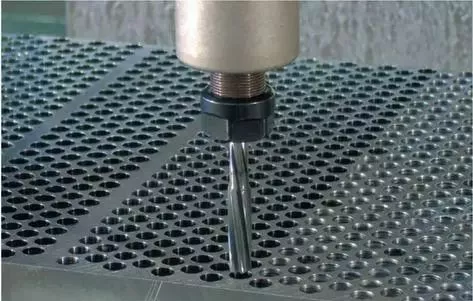

CNC drilling is the first step in machining holes in solid materials, and the drilling diameter is generally less than 80mm. There are two ways of drilling: one is the…

CNC drilling technology has been widely applied in modern manufacturing, especially showing great potential in micro – hole machining. The demand for micro – hole machining is becoming more and…