CNC Machining Parts Suppliers

CNC Basics Materials Guide Machining Processes Quality Standards Supplier Selection Case Studies Why Your CNC Supplier Matters More Than You Think Let’s cut to the chase – choosing the wrong…

CNC Basics Materials Guide Machining Processes Quality Standards Supplier Selection Case Studies Why Your CNC Supplier Matters More Than You Think Let’s cut to the chase – choosing the wrong…

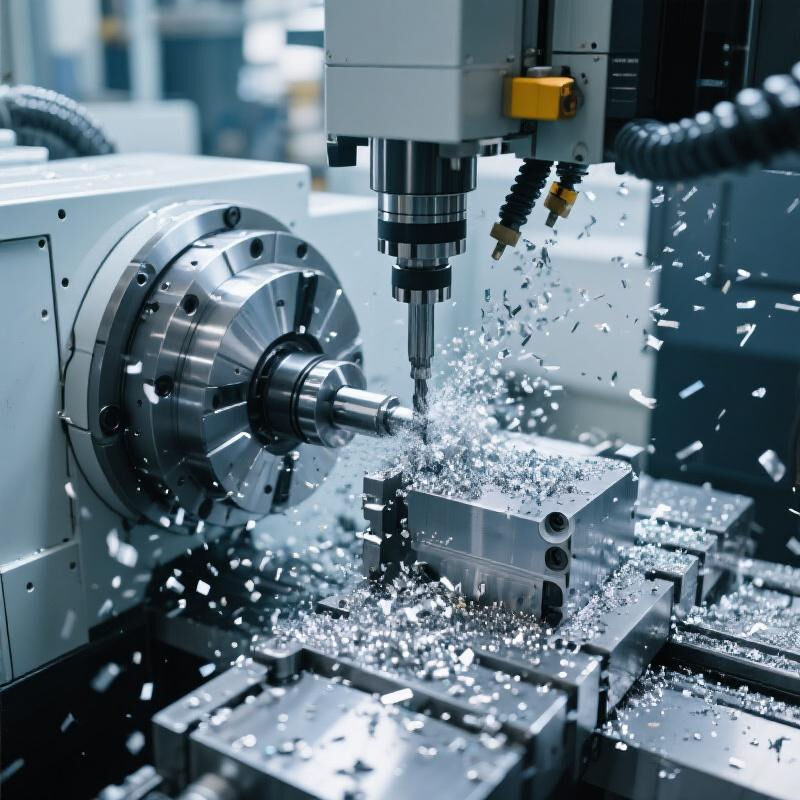

CNC Principles Materials Guide Cost Calculation DFM Design 2026 Trends Case Studies Problem Solving Why CNC Machining Matters in 2026 Let’s be real – if you’re in manufacturing, you know…

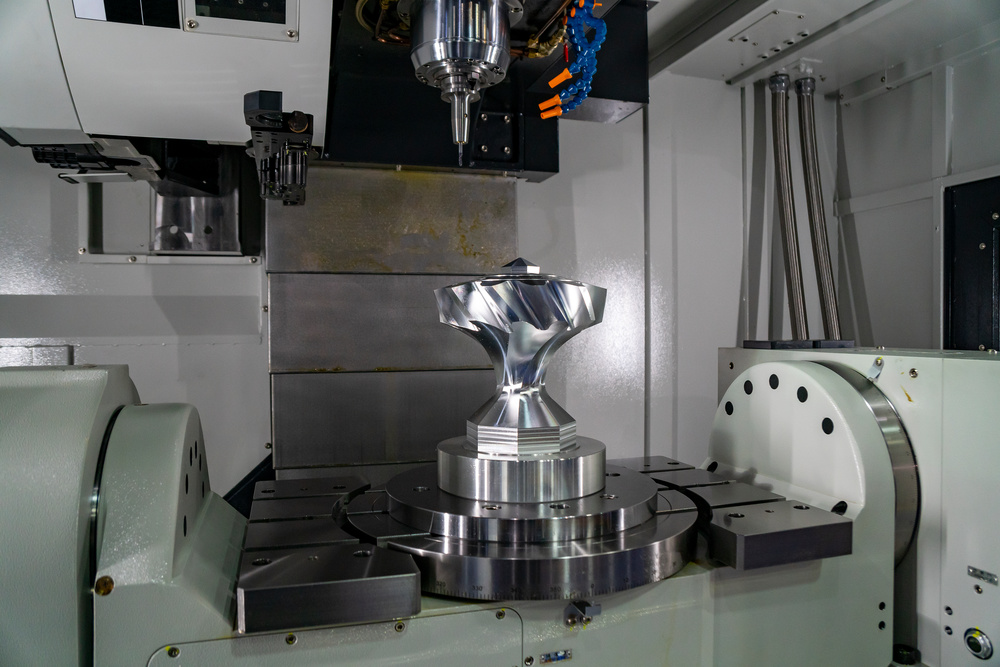

Basics vs 3/4 Axis Materials Applications Costs Defects AI Integration Hybrid 2026 Trends FAQ 5-Axis CNC – What You Actually Need to Know 5-axis CNC machining center producing complex aluminum…

Basics Materials Processes Applications CNC vs 3D Print Costs Defects 2026 Trends Programming FAQ CNC Machining – What You Actually Need to Know 5-axis CNC machining center producing complex aluminum…

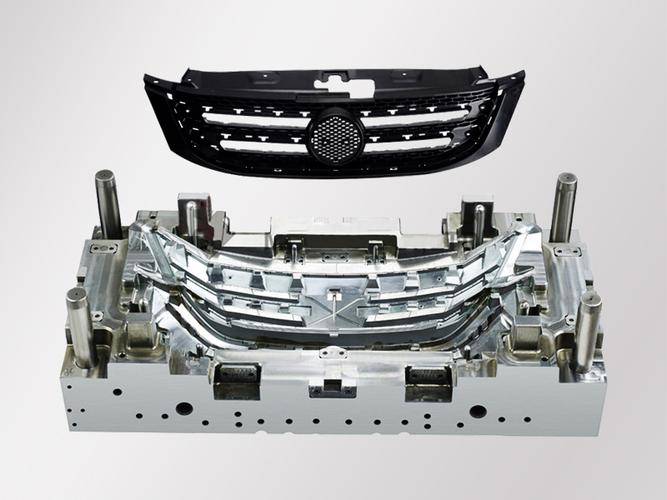

Bro, Let’s Talk About REAL Bumper Molds! Alright listen up, if you’re in the auto industry, you KNOW that bumper molds are the backbone of vehicle manufacturing. I’ve messed around…

Complete Guide with Real Data, Defect Costs, and Sustainability Trends Custom CNC Cost Cost Calculator Defect Costs 2026 Sustainable Machining Quick Answer: What’s the Real Cost in 2026? Custom CNC…

I. Underlying Technical Architecture and Machine Tool System of Turning Machining (A) Classification of Machine Tools and Core Performance Indicators Turning equipment can be categorized by structural form into: …

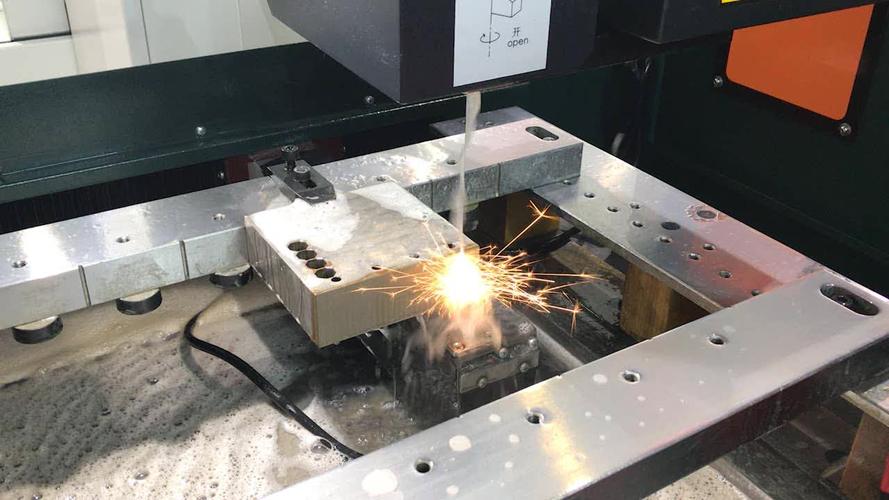

1. Technical Origin and Core Breakthrough: The Evolution from Electrical Discharge to Precision Machining The technological roots of wire electrical discharge machining (WEDM) can be traced back to the foundational…

In the field of precision machining in modern manufacturing, Electrical Discharge Machining (EDM) has become an indispensable key technology due to its unique processing method and significant advantages. Emerging in…

I. Definition of CNC Multi – axis Machining CNC multi – axis machining, namely Computer Numerical Control Multi – axis Machining, is an advanced CNC machining technology that adds rotation…