2026 CNC Machining Service Guide

CNC Principles Materials Guide Cost Calculation DFM Design 2026 Trends Case Studies Problem Solving Why CNC Machining Matters in 2026 Let’s be real – if you’re in manufacturing, you know…

CNC Principles Materials Guide Cost Calculation DFM Design 2026 Trends Case Studies Problem Solving Why CNC Machining Matters in 2026 Let’s be real – if you’re in manufacturing, you know…

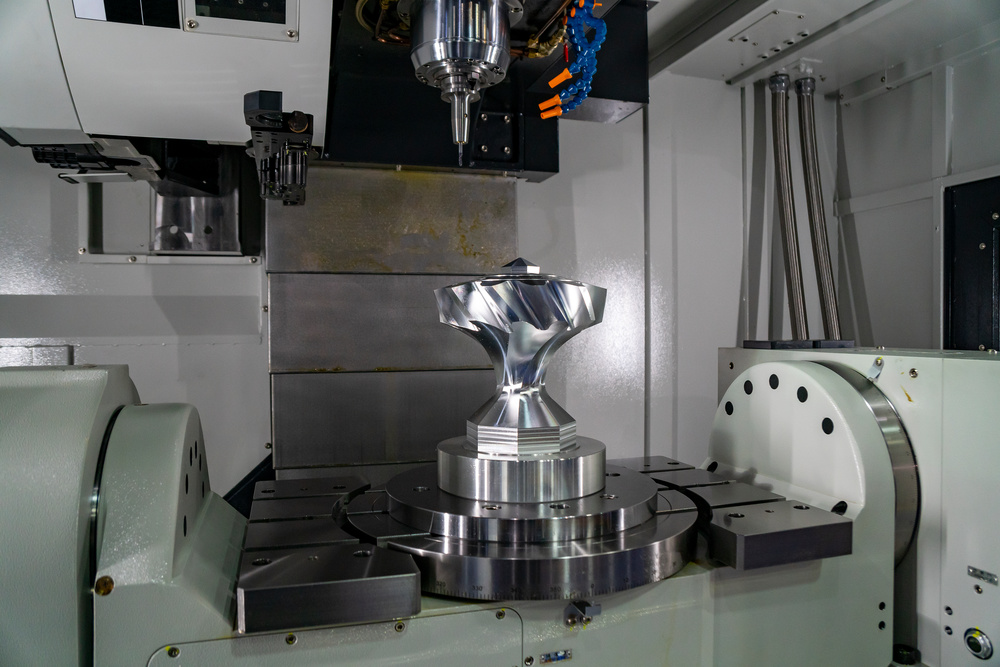

Basics vs 3/4 Axis Materials Applications Costs Defects AI Integration Hybrid 2026 Trends FAQ 5-Axis CNC – What You Actually Need to Know 5-axis CNC machining center producing complex aluminum…

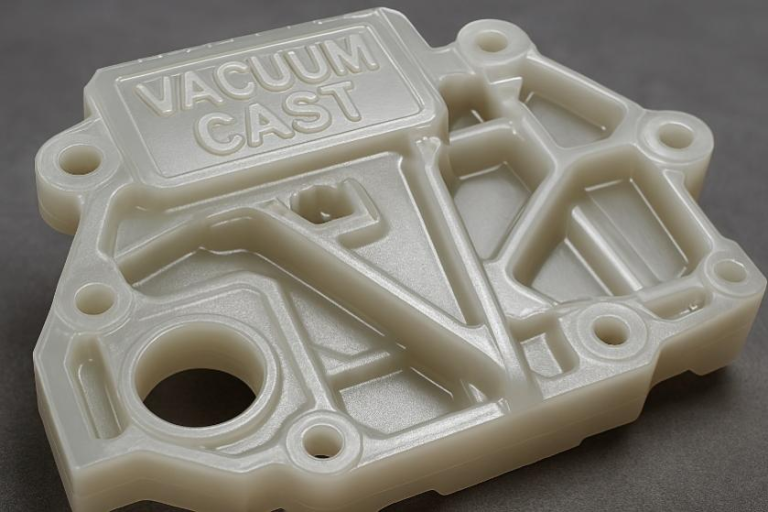

From an 18-year grizzled vet – real-world tips, 2026 trends, and the mistakes that cost me sleep (and clients) Listen Up, Engineers! You think you know precision molding? Think again….

Why Custom Hoods Are a 2026 Hot Topic? We at Goldcattle have 15 years of hood modification experience. Ever seen a race car driver’s hands burn from a hot hood?…

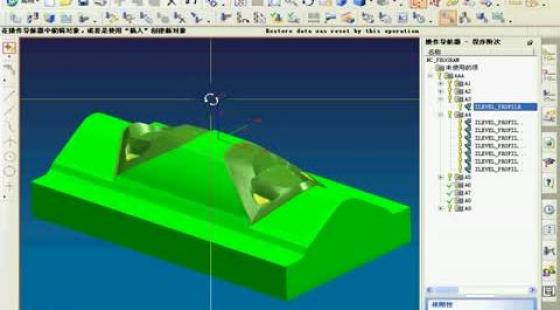

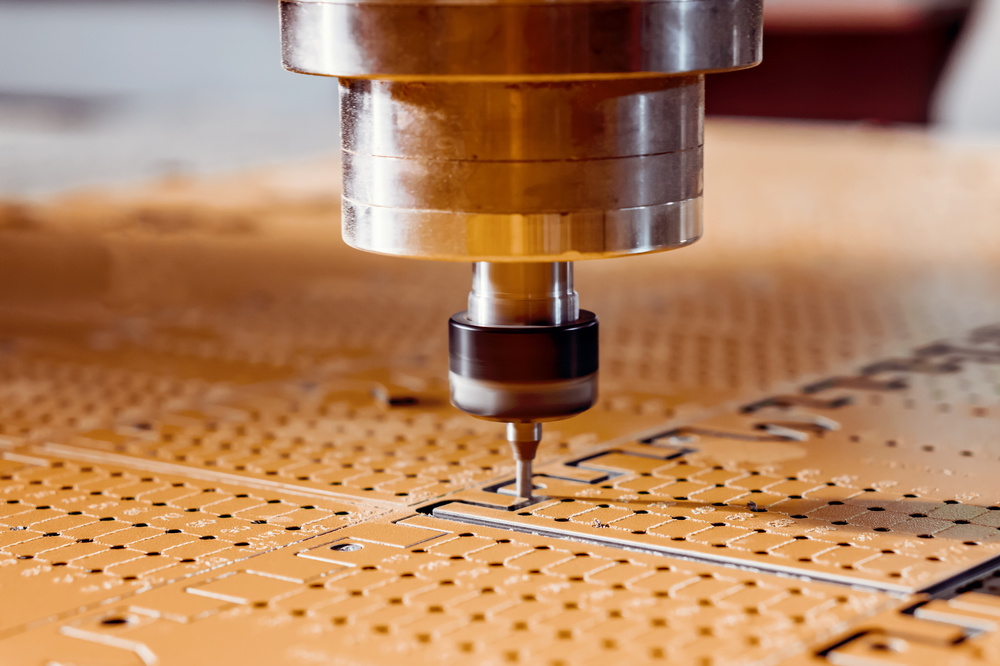

CNC milling contour lines, also known as Z-level machining or contour parallel toolpaths, are horizontal cutting paths generated at specific Z-heights that follow the surface geometry of a workpiece. This…

Ripple Milling is an advanced CNC machining technique. It uses a rippled toolpath to maintain a constant material removal rate. This significantly boosts machining efficiency and protects both the machine…

The answer is: No, vertical movement on CNC mills doesn’t have to use G01! The choice between G00, G01, or other G-codes depends on the purpose of the movement and…

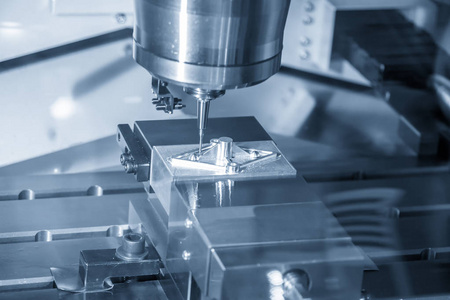

Yes, it can! An end mill can not only make a cube, but it can make it very precisely! Today I want to show you an amazing “metal transformation magic…

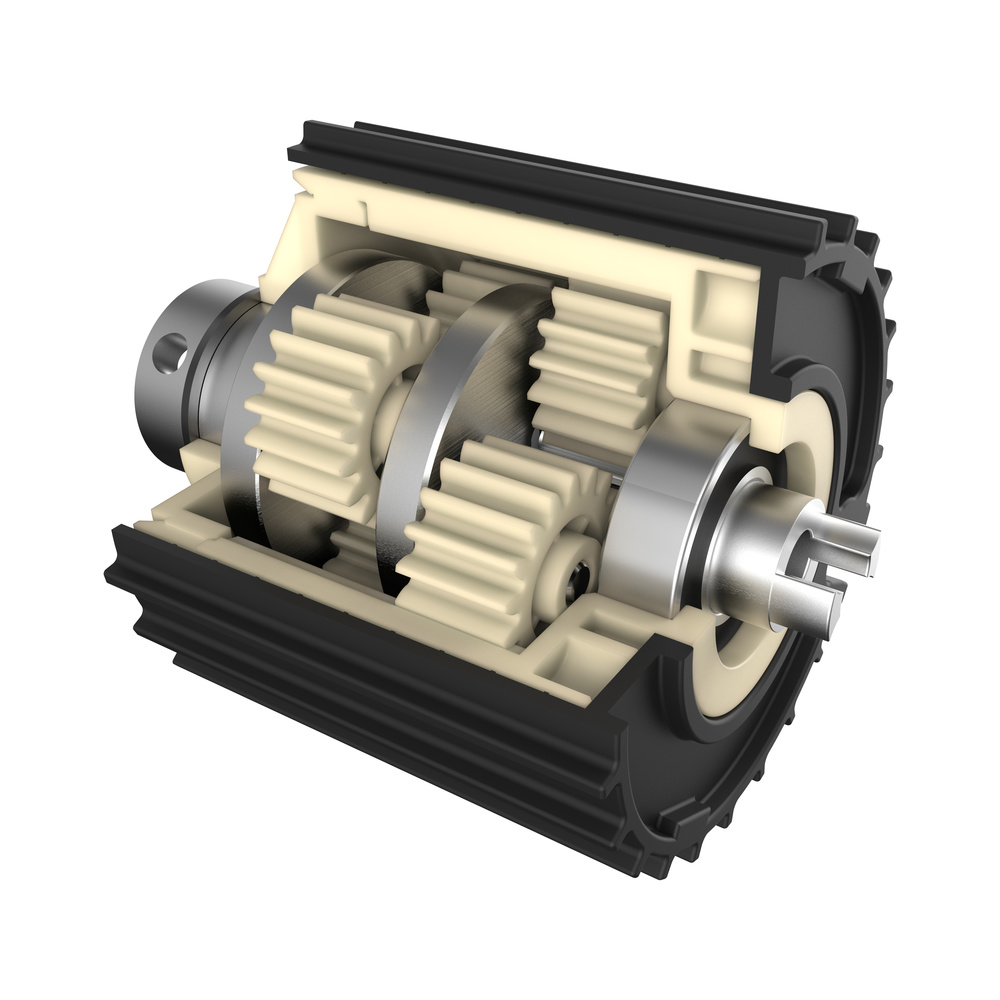

Why Every Machine You Use Relies on Tiny Metal Gears Have you ever wondered how your car’s engine power gets to the wheels? Or how your washing machine spins clothes…

Why Your Car’s Smooth Ride Depends on Invisible Technology Have you ever wondered how your car glides smoothly down the highway, even at high speeds? Or how it manages to…