What is CNC thread machining?

CNC thread machining is a precision manufacturing process that uses computer-controlled machine tools (lathes, mills) to create internal or external threads on workpieces. It employs tools like taps, thread mills,…

CNC thread machining is a precision manufacturing process that uses computer-controlled machine tools (lathes, mills) to create internal or external threads on workpieces. It employs tools like taps, thread mills,…

Xiamen Goldcattle, with 26 years in precision bearing component manufacturing, specializes in custom mechanical bearing parts—covering bearing rings, rollers, cages, seals, and adapter sleeves (steel/stainless/ceramic materials). Crafted via advanced CNC…

CNC machined mechanical parts are precision components crafted using computer-controlled tools to shape metal, plastic, or composite materials into exact specifications. These parts offer exceptional accuracy, tight tolerances, and consistent…

Author: Zhang Gong, CNC Expert with 18+ years experience | Last Updated: January 21, 2026 | Alright folks, let’s cut to the chase! In manufacturing, CNC stands for Computer Numerical…

CNC water jet cutting is an advanced manufacturing process that uses a high-pressure stream of water (often mixed with abrasive particles) to cut materials. Controlled by CNC systems, it slices…

CNC pipe bending is an automated manufacturing process that uses Computer Numerical Control (CNC) systems to precisely bend metal or plastic pipes into predefined shapes. It replaces manual bending by…

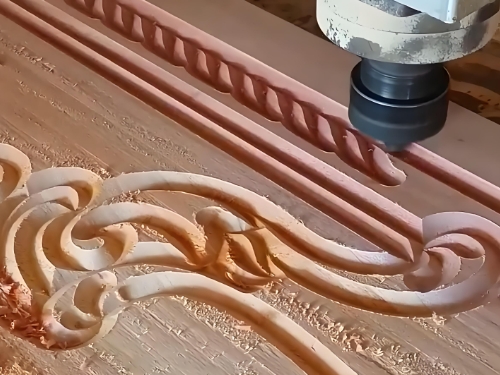

CNC wood carving is a computer-controlled manufacturing process that uses pre-programmed software to automate the carving, engraving, or shaping of wood. It employs CNC (Computer Numerical Control) machines equipped with…

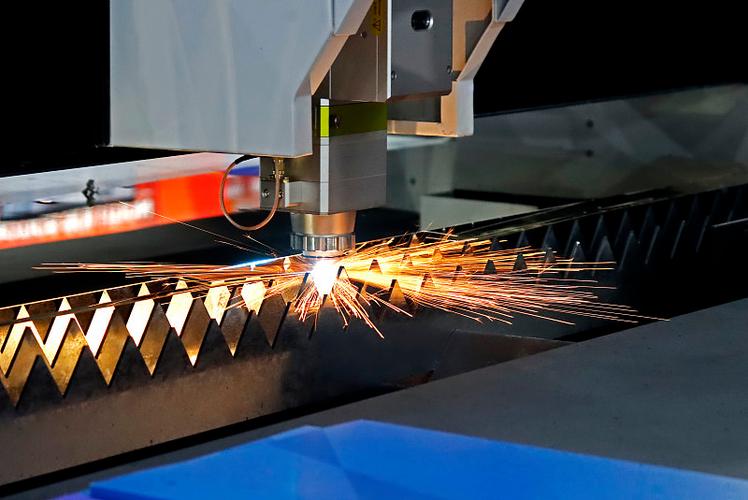

CNC laser cutting is a precision manufacturing process that uses a high-powered laser beam, controlled by computer numerical control (CNC) systems, to cut, engrave, or shape materials. The laser, focused…

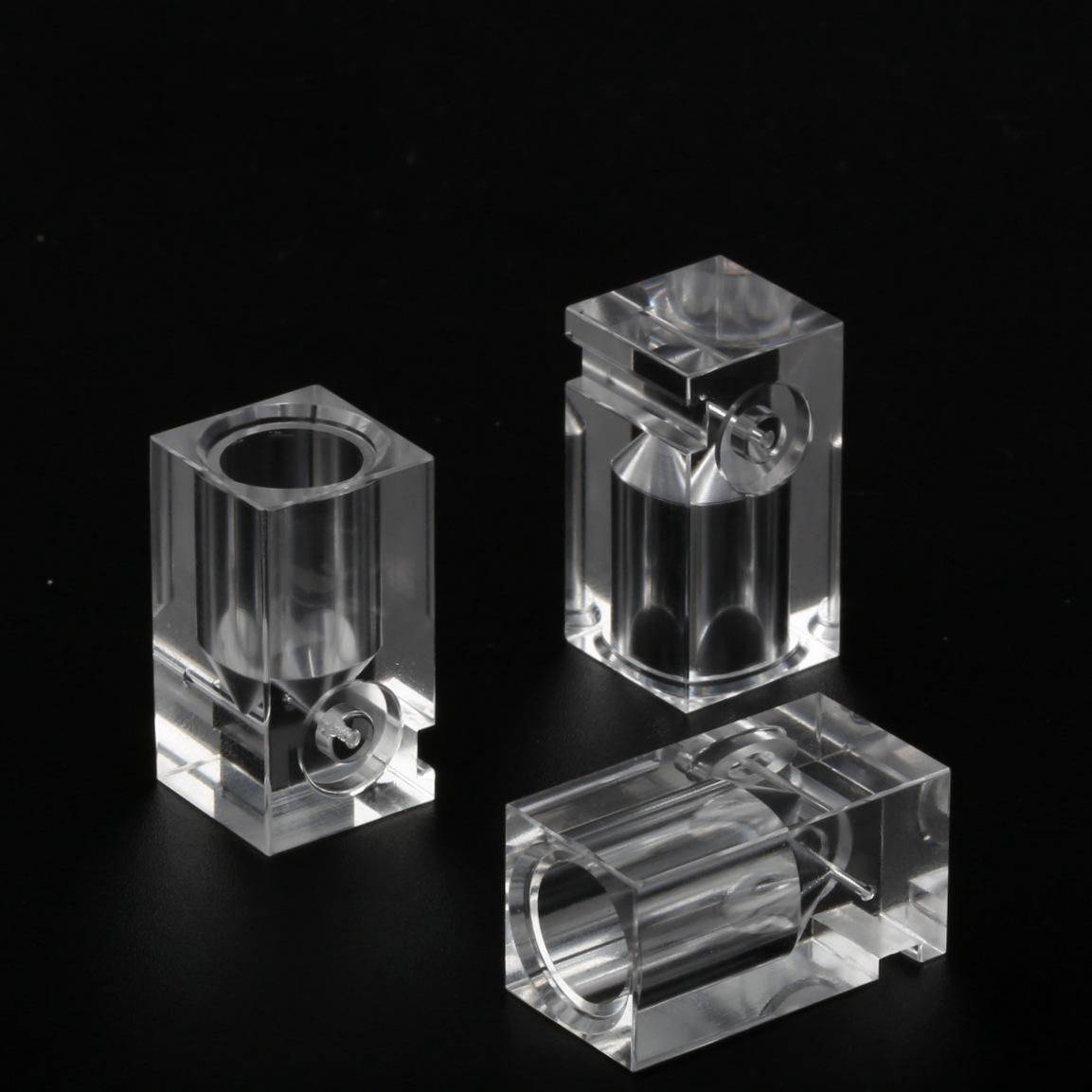

Acrylic CNC service refers to a specialized manufacturing process that uses Computer Numerical Control (CNC) machines to cut, shape, engrave, or mill acrylic (also known as PMMA, or polymethyl methacrylate)…

5 axis machining is an advanced CNC (Computer Numerical Control) manufacturing process that enables a cutting tool to move along five different axes simultaneously. Unlike 3 axis machines, which operate…