Top 10 Custom Injection Molding Suppliers in China 2026

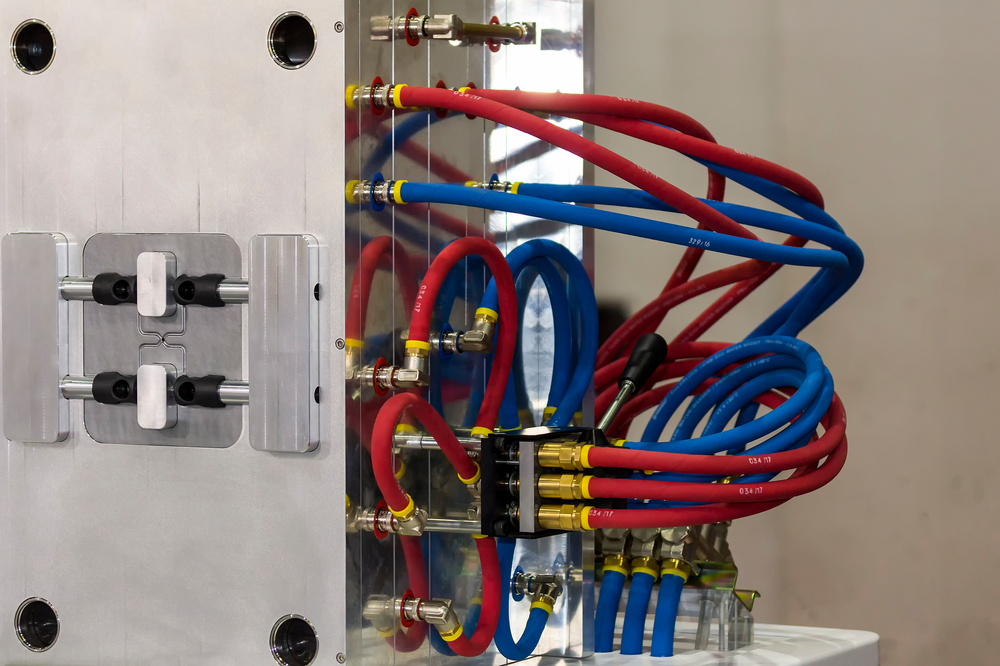

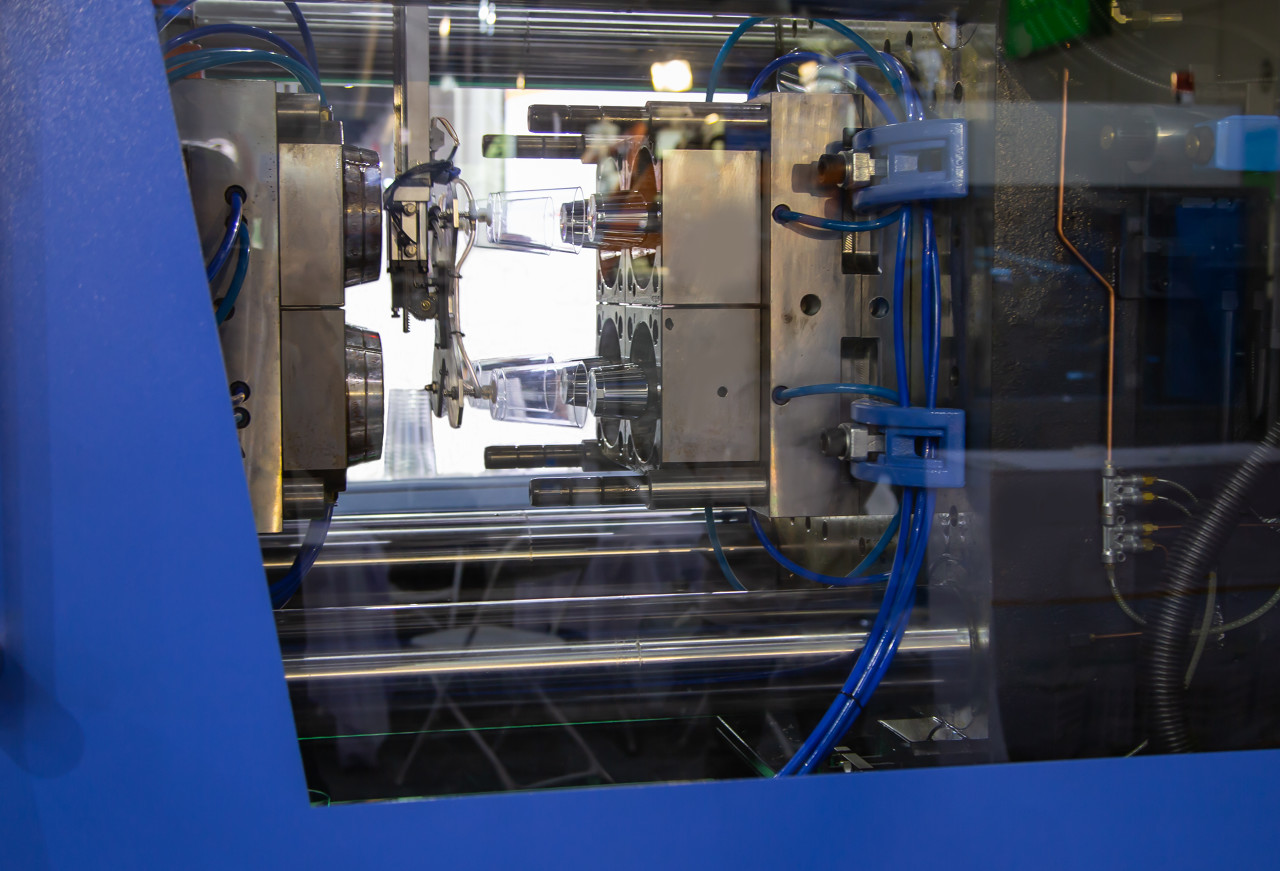

A Curated Guide to Reliable Manufacturers for Precision Plastic Parts – 2026 Updated Why This Guide Matters for Your Injection Molding Needs Modern injection molding workshop with automated production lines…