Progressive stamping, a highly efficient and precise metal – forming process, enables the continuous stamping and forming of metal sheets by setting up multiple workstations on a single set of dies. This technology has been widely applied in various fields such as automotive, electronics, and home appliances. With its advantages of high precision, high efficiency, and low cost, it has become an indispensable part of modern manufacturing. This article will delve into the technical details, application advantages, latest developments, and future trends of progressive stamping, providing valuable insights for professionals.

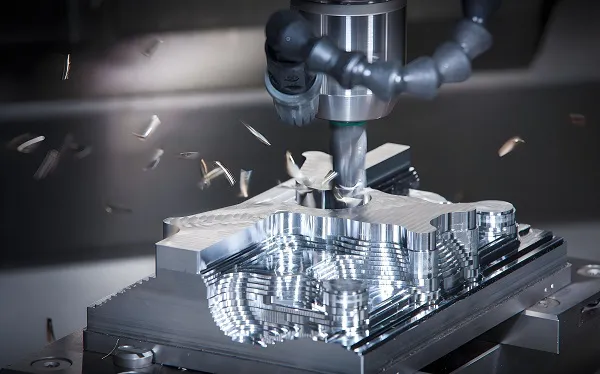

The working principle of progressive stamping is based on the plastic deformation of metal sheets. During the stamping process, the metal sheet is continuously fed into the die, and stamping and forming are carried out step – by – step through multiple workstations on the die. Each workstation is responsible for completing one stamping process, such as blanking, punching, bending, drawing, etc., and finally, the desired part shape is obtained.

Die design is the core of progressive stamping technology. A complete set of progressive stamping dies usually consists of multiple modules, with each module corresponding to one workstation. When designing the die, factors such as the fluidity of the metal sheet, forming force, and die life need to be considered to ensure the smooth progress of the stamping process and the stability of part quality.

With the development of automation and intelligent technologies, progressive stamping production lines have achieved a high degree of automation. By integrating advanced control systems and sensor technologies, the status of the stamping process can be monitored in real – time, and process parameters can be automatically adjusted to improve production efficiency and product quality.

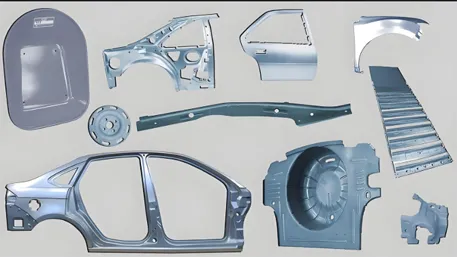

Progressive stamping can achieve high – precision stamping and forming, ensuring the accuracy of part dimensions and shapes. At the same time, since the stamping process is carried out continuously on the same set of dies, the consistency between parts is also effectively guaranteed.

Compared with traditional single – station stamping, progressive stamping can significantly improve production efficiency. By setting up multiple workstations on the same set of dies, the continuous stamping and forming of metal sheets are realized, reducing the time for die change and adjustment. In addition, due to the increase in production efficiency, production costs are also effectively reduced.

Progressive stamping is suitable for the stamping and forming of various metal sheets, including common metal materials such as steel, aluminum, and copper. At the same time, this technology can also handle complex part shapes and structures, meeting the production needs of different industries and products.

With the development of new materials and new processes, progressive stamping technology is also constantly innovating. For example, the application of new metal materials such as high – strength steel and aluminum alloy poses new challenges to die design and stamping processes. At the same time, new technologies such as laser cutting and 3D printing also provide new processing methods for progressive stamping.

Intelligence and digitalization have become the development trend of the manufacturing industry. In the field of progressive stamping, by integrating advanced technologies such as the Internet of Things, big data, and artificial intelligence, real – time monitoring and optimization of the production process can be achieved. For example, by collecting and analyzing data during the stamping process, the wear of the die can be predicted, and maintenance and replacement can be carried out in advance to reduce the risk of production interruption.

With the continuous progress of technology, progressive stamping will achieve higher – precision and more efficient stamping and forming. For example, by optimizing die design and stamping process parameters, the dimensional accuracy and shape accuracy of parts can be further improved; at the same time, by integrating more advanced automation and intelligent technologies, production efficiency can be further enhanced.

With the development of new materials and new processes, progressive stamping will be applied in a wider range of fields. For example, in high – end manufacturing fields such as new energy vehicles, aerospace, and medical devices, the demand for high – precision and highly complex parts is increasing, which will provide more market opportunities for progressive stamping.

Sustainable development and environmental protection have become the focus of global attention. In the field of progressive stamping, by using environmentally friendly materials and processes, optimizing energy use, etc., the environmental impact during the production process can be reduced. For example, measures such as using renewable materials to manufacture dies and recycling stamping waste help to achieve green production.

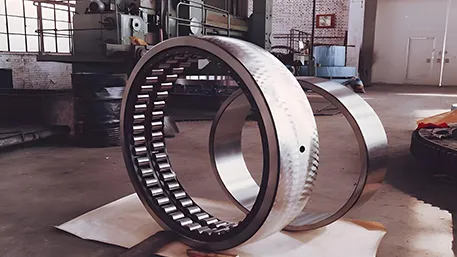

In the technical analysis of progressive stamping, we also need to pay attention to the issues of die life and maintenance. As a key component of stamping and forming, the life and maintenance status of the die directly affect production efficiency and product quality. Therefore, during die design and manufacturing, performance requirements such as wear resistance and impact resistance of materials need to be fully considered; at the same time, during use, the die needs to be regularly inspected and maintained, and severely worn parts need to be replaced in a timely manner to ensure the stability and reliability of the die.

In addition, with the development of digital and intelligent technologies, progressive stamping production lines will achieve more intelligent production and management. For example, by integrating the Internet of Things and big – data technologies, the operating status of the production line and part quality can be monitored in real – time; by applying artificial intelligence technology, intelligent control and optimization of the production process can be realized. This will help to further improve production efficiency and product quality and promote the continuous development of progressive stamping technology.