As functional components widely used in industrial fields, brass parts derive their core value from the adjustable properties of copper-zinc alloys and adaptable processing technologies. In scenarios such as fluid control, precision machinery, and electrical connection, their selection and application must be based on technical parameters to achieve precise performance.

1. Correlation Between Alloy Composition and Performance

The basic composition of brass consists of copper (Cu, 60%-75%) and zinc (Zn, 25%-40%), and the ratio of these two elements directly determines the core performance of the parts:

- High-copper alloys (≥70%, e.g., red brass): With an elongation of ≥45% and hardness ≤80HB, they are suitable for precision thin-walled parts requiring cold stamping (e.g., electrical connectors).

- High-zinc alloys (≤35%, e.g., yellow brass): Featuring a tensile strength of ≥400MPa and hardness ≥110HB, they are adapted for structural parts bearing moderate loads (e.g., pipe supports).

To enhance specific performance, trace alloying elements are added:

- Lead (Pb, 0.8%-3.5%): Reduces cutting resistance, enabling parts to reach IT6 grade machining accuracy, suitable for complex structural parts processed by CNC milling.

- Tin (Sn, 0.5%-2%): Improves seawater corrosion resistance (salt spray test ≥500h), forming naval brass for marine pipeline parts.

- Arsenic (As, 0.02%-0.05%): Inhibits dezincification corrosion, extending the service life of hot water pipeline parts.

2. Core Processing Technologies and Technical Requirements

Processing technologies for brass parts must match precision and batch requirements, with mainstream technical routes including:

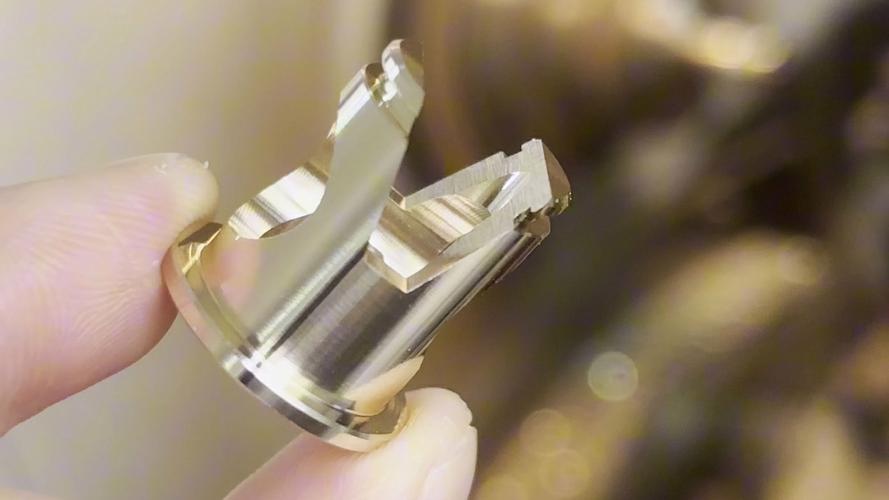

- CNC Precision Machining: Using cemented carbide tools (e.g., WC-Co tools) at a spindle speed of 8,000-12,000r/min, achieving a hole diameter tolerance of ±0.01mm. It is suitable for high-precision parts such as sensor housings and valve cores.

- Sand Casting: Applied to complex parts with a wall thickness of ≥5mm (e.g., valve bodies). The density of castings (porosity ≤2%) must be controlled to avoid pressure leakage.

- Cold Extrusion Molding: Leveraging the high plasticity of brass (section shrinkage rate ≥60%) to achieve non-cutting processing, increasing part strength by 15%-20% compared to cast parts. It is commonly used for mass-produced bolts and nuts.

3. Typical Engineering Application Scenarios

- Fluid Control Field: Brass parts must meet pressure resistance (≥1.6MPa) and sealing requirements. For example, pipe joints adopt a conical sealing structure with nitrile rubber O-rings, ensuring a leakage rate of ≤0.01mL/min.

- Electrical Field: With an electrical conductivity of ≥28MS/m, brass parts require nickel plating (plating thickness 5-10μm) to reduce contact resistance (≤5mΩ), suitable for terminals and switch contacts.

- Musical Instrument Field: Brass must have stable acoustic impedance (approximately 38×10^6 kg/(m²·s) at 20℃), and the surface roughness of parts should be Ra ≤0.8μm to avoid airflow disturbance affecting tone.

4. Quality Judgment and Selection Criteria

-

Quality Inspection Indicators:

- Composition: Using a spectral analyzer to ensure the deviation of alloy elements is ≤±0.2%.

- Dimensional Accuracy: Verifying key dimension tolerances against the GB/T 15746 standard (China National Standard) via a coordinate measuring machine.

- Corrosion Resistance: After the Neutral Salt Spray (NSS) test, the corrosion area should be ≤5%.

-

Selection Principles:

- Choose alloys based on working conditions: Lead brass for hot water environments, tin brass for marine environments.

- Select processes based on precision: CNC grinding for IT5 grade precision parts, cold extrusion for mass-produced parts.

- Opt for surface treatments based on the environment: Cadmium plating (superior corrosion resistance to nickel plating) for humid environments, natural oxidation for high-temperature environments.

The core of brass part application lies in the technical matching of “performance-process-working conditions”. Through composition adjustment, process optimization, and precise testing, the engineering goals of functionality and service life can be achieved—rather than relying solely on appearance or material gimmicks.