As the Long March 5 carrier rocket roared through the clouds, the inner wall of the third-stage hydrolox engine nozzle was simultaneously enduring the scorching of -253℃ liquid hydrogen and 3300℃ combustion gas. Those invisible ceramic coatings, with a thickness of merely 0.01 millimeters, were building a microscopic defense line on the metal surface—this is the most concrete battlefield for aerospace coatings, where every molecule engages in a silent wrestling match with extreme environments.

I. A Battle for Survival at the Atomic Level

The silence of low Earth orbit hides violent secrets. Three million atomic oxygen particles per second collide with the International Space Station’s portholes at 8 kilometers per second, equivalent to continuous sanding with sandpaper for 15 years. Russian astronauts once discovered that an unprotected titanium alloy antenna bracket had been etched into a honeycomb-like pattern of pits over three years, with the deepest reaching 0.2 millimeters.

This “space weathering” has forced coating technology toward precision. The Cerakote coating designed by Protolabs for a satellite’s solar panel must meet three conflicting specifications: maintaining a high friction coefficient of 0.8 on the ground to prevent sliding during transportation, dropping to 0.2 after entering orbit to ensure smooth deployment, and withstanding ±180℃ day-night temperature fluctuations. Researchers observed under a microscope that ceramic particles in the coating contract and expand with temperature like scales, forming a dynamic protective network.

II. The Three-Layer “Vital System” of Coatings

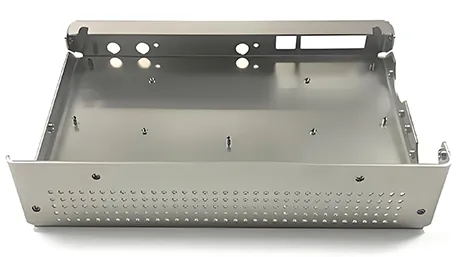

Aerospace coatings are never a single film but a precisely collaborative “ecosystem.” In Protolabs’ CNC machining workshop, an aluminum alloy cabin door component undergoes a standardized three-layer treatment:

The chromate conversion coating forms the first line of defense. Nanoscale chromium oxides build an electrochemical barrier on the metal surface, resisting corrosion for 1000 hours in salt spray tests. The middle Cerakote ceramic layer is nothing short of a “space fireproof suit”—a 0.05-millimeter thickness allows titanium alloy to remain structurally stable at 1200℃, while its porous structure reduces thermal conductivity. The outermost anodized layer carries a human touch: its deep space gray and aerospace white surfaces reflect 60% of solar radiation while meeting NASA’s flame-retardant standards.

The “ice-fire coating” developed by engineers at the Shanghai Academy of Spaceflight Technology for the Long March rocket is even more exquisite. Hyperbranched polymer molecules intertwine like tree branches, retaining rubber-like elasticity on the -183℃ liquid oxygen tank surface, yet quickly carbonizing into a heat-insulating honeycomb structure when the rocket encounters 500℃ aerodynamic heat during atmospheric penetration.

III. The Symbiosis of Craftsmanship and Coatings

The vitality of a coating often lies in the details of manufacturing processes. Protolabs’ workshop records show that aluminum alloy treated with bead blasting (Ra 3.2μm) after CNC machining has an anodized layer with 40% stronger adhesion than mirror-finished parts—those seemingly rough micro-pits, in fact, act as “anchors” for the coating.

3D-printed fuel nozzles require gentler care. Nylon components produced via Multi Jet Fusion, after vapor smoothing, see their porosity drop from 15% to 1.2% and water vapor permeability reduced by 90%. Technicians run their fingertips over the treated surface, noting a texture similar to frosted glass—a sign that the coating has seeped into every micron-scale crevice.

Powder coatings for sheet metal parts walk a tightrope between weight and protection. A drone wing uses an ultra-thin 50μm powder coating, 30 grams lighter than traditional spray paint. Its pre-treatment with zirconium conversion (replacing toxic chromates) gives it an ISO 2409 Class 0 adhesion rating. Under an electron microscope, these zirconium-based compounds spread like ferns across the metal surface, providing a perfect base for subsequent coatings.

IV. An Afternoon by the Salt Spray Chamber

In the corrosion laboratory of Florida’s launch center, the salt spray chamber hums continuously. Technician Mark uses tweezers to extract a titanium alloy connector produced by Protolabs; beneath the white salt crust, the Cerakote coating shimmers with iridescence. He scrapes the edge gently with his fingernail, and the coating curls slightly like sun-dried skin, revealing the intact metal beneath.

Under a magnifying glass on the adjacent workbench, a 3D-printed fuel valve drips with seawater-simulating solution. The vapor-smoothed surface glistens with fine water droplets, as if coated in an invisible wax. Mark remembers the rocket debris recovered last week—those coating fragments that survived atmospheric re-entry, their cross-sections glowing purplish-blue under light, traces of ceramic crystallization from extreme heat.

A click comes from the aging test chamber in the corner, where coating samples undergo their 5000th thermal cycle. Mark knows that by dawn, some samples will show tiny cracks. But others? They’ll remain as they were, unyielding after enduring -196℃ to 150℃.