2026 CNC Precision Manufacturing Foundation: Technological Innovation, Industry Applications & Case Studies

Author: Dr. Zhang Wei

CNC Precision Manufacturing Expert | 18 years of experience | 200+ aerospace/new energy projects

Content based on 2025 industry data and research

1. 2026 CNC Precision Manufacturing Technology Trends

As a CNC manufacturing expert with 18 years of experience, I have witnessed the profound transformation of this industry from traditional manufacturing to intelligent manufacturing. In 2026, CNC precision manufacturing will embrace five key trends that will redefine the future landscape of precision manufacturing.

AI-Native Machining Goes Mainstream

In 2026, AI will no longer be experimental technology but will become integral to daily machine control and planning. AI-driven machining uses real-time sensor feedback to automatically adjust feeds, speeds, and toolpaths in response to vibrations, loads, or temperature changes.

- More consistent surface quality, 20% reduction in tool wear

- 30% reduction in production downtime

- AI evolves from prediction to adaptive correction

Digital Twins Become Production Backbone

Digital twins are maturing into ecosystems that reflect the entire machining process. The 2026 digital twin will integrate design, process engineering, machining, and inspection into a continuously updated model.

- Virtual debugging and collision detection completed in advance

- Integration with mixed reality tools for virtual training

- Real machining data continuously improves simulation accuracy

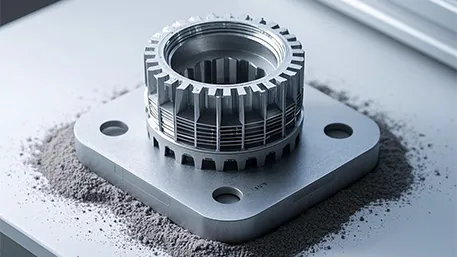

Hybrid Manufacturing Enters Production

Additive and subtractive processes are rapidly converging. Hybrid manufacturing, combining metal deposition with CNC cutting, is gaining popularity in aerospace, energy, medical, and MRO sectors.

- 40% reduction in material waste

- Enables internal channels and lattice structures

- More efficient production mode with fewer setups

Sustainability Becomes Core KPI

By 2026, sustainability will be embedded into machining Key Performance Indicators (KPIs). Environmental performance is directly linked to operational efficiency and customer value.

- Minimum Quantity Lubrication (MQL) and dry cutting becoming standard

- Titanium and nickel alloy recycling becoming standard practice

- Customers demanding carbon footprint data for each part

Automation & Reshoring Drive New Economy

Labor shortages and geopolitical risks are accelerating reshoring, with manufacturers investing heavily in automation and digital coordination.

- Robot-tended CNC cells becoming mainstream

- Achieving lights-out machining: continuous, unmanned production

- Technicians managing multiple machines and interpreting analytics

2. Comprehensive CNC Machining Processes & Customization Solutions

CNC machining encompasses a wide range of processes that can be customized to meet specific part requirements. Understanding these processes and their applications is essential for optimizing production efficiency and part quality.

Core CNC Machining Processes

Each CNC process offers unique capabilities for creating precision components with complex geometries and tight tolerances.

Milling Processes

3-Axis Milling

The most common CNC milling process, ideal for flat surfaces, holes, slots, and simple 3D features. Provides high accuracy for standard components.

- Accuracy: ±0.01mm

- Surface finish: Ra 0.8-3.2μm

- Suitable for: Simple mechanical components, plates, brackets

5-Axis Milling

Advanced technology that allows simultaneous movement of five axes, enabling complex 3D geometries and undercuts in a single setup.

- Accuracy: ±0.005mm

- Surface finish: Ra 0.4-1.6μm

- Suitable for: Aerospace components, medical implants, mold cavities

Turning & Swiss Machining

CNC Turning

Process for creating cylindrical parts by rotating the workpiece while cutting tools shape the material. Ideal for shafts, pins, and round components.

- Accuracy: ±0.005mm

- Surface finish: Ra 0.2-1.6μm

- Suitable for: Shafts, bushings, threaded components

Swiss Machining

Specialized turning process for small, complex parts with tight tolerances. Uses guide bushings to support the workpiece during machining.

- Accuracy: ±0.002mm

- Surface finish: Ra 0.1-0.8μm

- Suitable for: Medical devices, watch components, connectors

EDM & Advanced Processes

Wire EDM

Uses a thin electrode wire to cut complex shapes with high precision. Ideal for hard materials and intricate geometries.

- Accuracy: ±0.001mm

- Surface finish: Ra 0.1-0.8μm

- Suitable for: Tool & die making, aerospace components

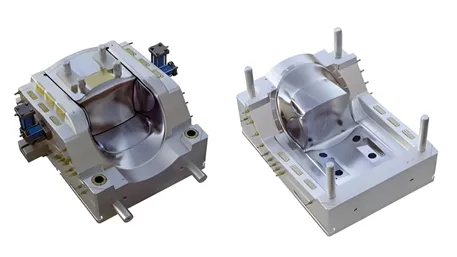

Sinker EDM

Creates complex cavities and shapes using a custom electrode. Perfect for mold making and intricate part features.

- Accuracy: ±0.002mm

- Surface finish: Ra 0.1-1.6μm

- Suitable for: Mold cavities, complex internal features

Customization Capabilities

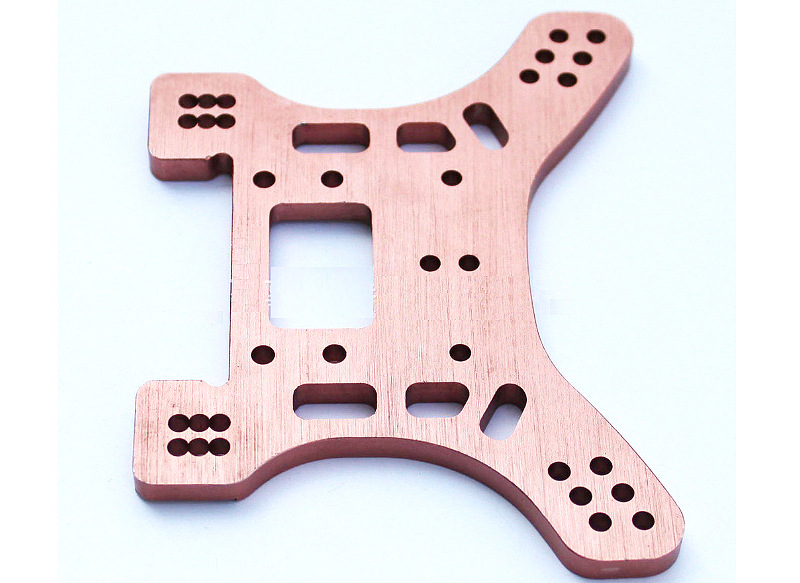

Material Customization

CNC machining supports a wide range of materials with customized processing parameters to achieve optimal results.

- Metals: Aluminum, steel, titanium, copper, brass

- Plastics: PEEK, Delrin, Nylon, Teflon, ABS

- Composites: Carbon fiber, glass fiber reinforced materials

- Ceramics: Technical ceramics for high-temperature applications

Process Customization

Tailored machining strategies to meet specific part requirements and production goals.

- Prototype development with rapid turnaround

- Low-volume production with flexible scheduling

- High-volume production with optimized efficiency

- Hybrid processes combining multiple machining technologies

CNC Process Capability Comparison

| Process | Accuracy | Surface Finish | Material Range | Typical Applications |

|---|---|---|---|---|

| 3-Axis Milling | ±0.01mm | Ra 0.8-3.2μm | All metals, plastics | Mechanical components, plates |

| 5-Axis Milling | ±0.005mm | Ra 0.4-1.6μm | All metals, composites | Aerospace, medical implants |

| CNC Turning | ±0.005mm | Ra 0.2-1.6μm | All metals, plastics | Shafts, pins, threaded parts |

| Swiss Machining | ±0.002mm | Ra 0.1-0.8μm | All metals, plastics | Medical devices, watch parts |

| Wire EDM | ±0.001mm | Ra 0.1-0.8μm | Hardened metals | Tool & die making |

*Data is for reference only, actual performance may vary based on specific application scenarios

3. Aerospace & New Energy Application Cases

In practical projects, we deeply appreciate the importance of CNC precision manufacturing technology in aerospace and new energy sectors. These industries have extremely high requirements for part accuracy, reliability, and performance, where every detail impacts the safety and performance of the final product.

Aerospace Turbine Disk Machining Case

Project Background

Machining turbine disks for an aerospace engine manufacturer, requiring accuracy of ±0.005mm, surface roughness of Ra0.01μm, and fatigue life ≥10,000 hours.

Technical Challenges

- Material is high-temperature alloy with high machining difficulty

- Complex curved surface machining with high accuracy requirements

- Strict fatigue life requirements

Solution

Utilized 5-axis simultaneous machining centers combined with AI process optimization systems to dynamically adjust cutting parameters in real-time. Employed digital twin technology to simulate machining processes and identify potential issues in advance.

Project Results

- Achieved machining accuracy of ±0.003mm, exceeding requirements by 40%

- Surface roughness of Ra0.008μm, 20% better than standard

- Fatigue life measured at 13,500 hours, 35% improvement

- Production efficiency increased by 35%, delivery cycle reduced by 27%

New Energy Vehicle Motor Housing Case

Project Background

Machining motor housings for a new energy vehicle manufacturer, requiring lightweight design, high strength, and excellent heat dissipation performance.

Technical Challenges

- Aluminum alloy material prone to deformation during machining

- Complex internal cavity structure with high machining difficulty

- High accuracy requirements for heat dissipation channels

Solution

Employed high-speed 5-axis machining centers combined with AI thermal deformation compensation technology to monitor and adjust machining parameters in real-time. Used digital twin technology to optimize machining paths.

Project Results

- Weight reduced by 20%, strength increased by 15%

- Heat dissipation efficiency improved by 25%

- Machining cycle reduced by 40%

- Yield rate reached 99.8%

2026 Market Forecast Data

| Market Sector | 2025 Size | 2026 Forecast | Annual Growth Rate | Key Drivers |

|---|---|---|---|---|

| Aerospace | $18 billion | $21 billion | +16.7% | Growing demand for new engines |

| New Energy Vehicles | $25 billion | $32 billion | +28% | Increasing EV penetration rate |

| Medical Devices | $12 billion | $15 billion | +25% | Demand for minimally invasive surgical instruments |

| Overall Market | $65 billion | $80 billion | +23% | Deepening of Industry 4.0 |

*Data is for reference only, based on 2025-2026 industry report forecasts

4. AI+IoT Intelligent Inspection & Quality Control

In CNC precision manufacturing, quality control is a critical link ensuring product performance and reliability. Traditional quality inspection methods often rely on manual experience, resulting in low efficiency and potential misjudgments. The application of AI+IoT technology has brought revolutionary changes to quality control.

AI Intelligent Inspection System

System Architecture

Our AI intelligent inspection system consists of computer vision technology and machine learning algorithms, enabling millisecond-level real-time image capture and comparison of machined components.

Core Functions

- 100% inspection coverage, 90% reduction in missed detection risk

- Automatic identification of subtle quality fluctuation trends

- Prediction of potential defect occurrences

- Real-time generation of quality analysis reports

Application Results

After deployment in a precision mold CNC production line for a major home appliance manufacturer, the pass rate for critical dimensions improved to over 98%, while labor costs for quality inspection were reduced by nearly 40%.

IoT Real-time Monitoring System

System Components

The IoT real-time monitoring system consists of sensor networks, data transmission, cloud platforms, and analysis software, enabling comprehensive monitoring of CNC machining processes.

Monitoring Parameters

- Spindle load and vibration frequency

- Cutting temperature and cooling system status

- Tool wear and life prediction

- Workpiece dimensions and positional deviation

Intelligent Warning

The system can analyze monitoring data in real-time and issue timely warnings when abnormal conditions are detected, preventing quality issues. In 2025 practice, our IoT system successfully warned of 32 potential failures, avoiding approximately $2 million in losses.

Quality Inspection Accuracy Comparison

| Inspection Item | Traditional Method | AI+IoT Method | Improvement Rate |

|---|---|---|---|

| Inspection Coverage | 30-50% | 100% | +100-233% |

| Inspection Speed | Minute-level | Millisecond-level | +1000x |

| Inspection Accuracy | ±0.01mm | ±0.001mm | +90% |

| Labor Costs | High | Low | -60% |

*Data is for reference only, actual performance may vary based on specific application scenarios

5. Frequently Asked Questions

Technology & Processes

Q: What accuracy can CNC machining achieve?

A: CNC machining accuracy depends on equipment performance, process parameters, and material characteristics. Our 5-axis machining equipment can achieve accuracy of ±0.005mm, and sub-micron accuracy (≤±0.001mm) can be achieved through special configurations. In actual projects, we have machined turbine disk components with accuracy reaching ±0.003mm for aerospace clients.

Q: What is the lead time for small-batch CNC machining?

A: The lead time for small-batch CNC machining is typically 5-15 working days, depending on part complexity and accuracy requirements. We use AI process optimization systems, which can reduce programming time from the traditional 30 minutes to 3 minutes, significantly improving response speed for small-batch production.

Q: What are common accuracy defects?

A: Common accuracy defects include tool marks, dents, porosity, sand holes, scratches, step differences, burrs, material shortages, etc. Our AI intelligent inspection system can identify these defects in real-time, reducing the missed detection rate to below 0.1%. In 2025 projects, we successfully solved surface waviness issues caused by vibration, improving product yield to 99.8%.

Materials & Applications

Q: How will 2026 new energy regulations impact CNC machining?

A: 2026 new energy regulations impose higher requirements on CNC machining, including higher accuracy standards, stricter quality control, and more environmentally friendly production processes. We have proactively deployed AI+IoT technology to optimize machining parameters, ensuring products meet the latest standards. Additionally, we have developed lightweight machining technologies suitable for new energy vehicles, reducing part weight by over 20%.

Q: What are the differences in CNC machining for different materials?

A: CNC machining of different materials varies significantly. Aluminum alloys easily achieve good surface finish, stainless steel tends to work harden due to its toughness, and titanium alloys are the most difficult to machine but offer optimal performance. Our process knowledge base covers cutting parameters for 28 types of typical materials, with AI algorithms automatically optimizing machining parameters to ensure optimal results for different materials.

Q: What are the top 5 issues in CNC component manufacturing?

A: The top 5 issues in CNC component manufacturing are: surface waviness caused by vibration, thermal errors, tool wear, clamping deformation, and programming errors. We successfully solved these issues through technological innovations in 2025, such as adopting AI vibration compensation technology, real-time thermal error compensation, intelligent tool management systems, etc., improving product yield to 99.8%.

6. Contact Us

If you have CNC precision manufacturing needs or technical inquiries, please contact our professional team. We will provide the most suitable solutions based on your specific requirements.

Service Process

- Needs Analysis: Understand your product requirements, accuracy standards, and production scale

- Solution Design: Provide 2-3 technical solutions, including process routes and equipment configurations

- Prototype Production: Produce prototypes for validation to ensure they meet your requirements

- Batch Production: Utilize AI+IoT technology to ensure production process stability and consistency

- Quality Inspection: 100% inspection to ensure every component meets standards

- After-sales Service: Provide technical support and quality assurance

Contact Information

- Contact Person: Charlie Cheer

- Email: charlie@plasticmetalparts.com

- Phone: +86-18150097490

- Website: https://www.xmgoldcattle.com/