CNC (Computer Numerical Control, computer numerical control) custom processing technology in the modern manufacturing industry occupies an important position, especially in the field of metal processing, its high precision, high efficiency features make CNC processing has become indispensable processing means. Metal stamping as an important process in metal processing, and the combination of CNC technology is to further enhance the processing quality and efficiency. The purpose of this paper is to introduce in detail the CNC customized processing of metal printing technology, including its type, process and precautions.

1. Metal printing type

In CNC custom processing, metal printing is mainly divided into two types: metal foil printing and metal powder printing.

1.1 Metal Foil Printing

Definition: metal foil printing is a printing method in which metal foil is transferred to the surface of the substrate through the action of heat or pressure.

Classification:

1.2 Hot press metal foil printing: metal foil is firmly attached to the substrate by heat and pressure. This method is suitable for fabric, leather, paper and other materials with a relatively flat surface, and can form a high gloss, high adhesion metal effect on the surface of the material.

Cold press foil printing: The foil is directly affixed to the substrate, and pressure is applied to make it close to the substrate. Cold pressing method is faster, the material surface flatness requirements are relatively low, but the adhesion may be slightly inferior to the hot pressing method.

1.3 Metal powder printing

Definition: metal powder printing is a mixture of metal powder and printing paste, through the printing technology on the surface of the substrate to form a metallic printing effect.

Characteristics: with significant metallic luster and three-dimensional sense, applicable to textiles, leather, plastics and other materials. Its printing effect is unique and can significantly enhance the grade and aesthetics of the product.

2. CNC custom processing in the metal printing process

2.1 Design pattern: first of all, design the pattern of metal printing according to the customer’s needs to ensure the clarity and precision of the pattern.

2.2 Prepare materials: choose suitable substrates for metal printing (such as metal plate, metal sheet, etc.) and metal foil or metal powder printing materials.

2.3 CNC programming: according to the designed pattern and size of the substrate, carry out CNC programming to determine the processing path, cutting parameters, etc..

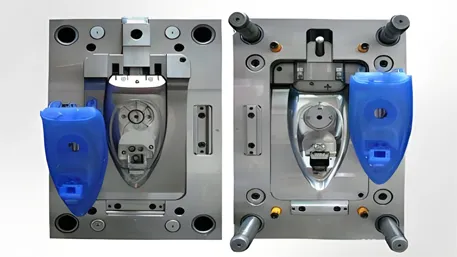

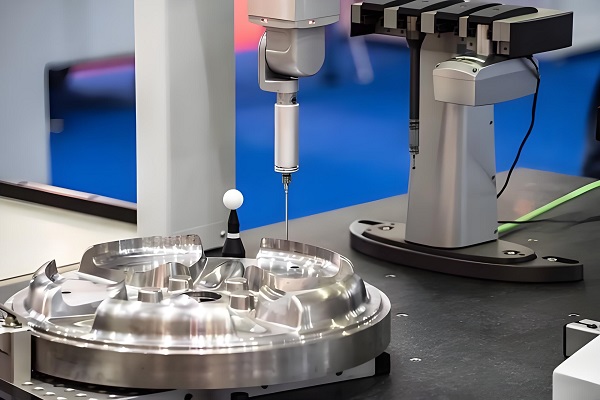

2.4 CNC processing: use CNC machine tools for processing, through precise control of the movement path of the tool and the depth of cut, the desired pattern contour is processed on the surface of the substrate.

2.5 Metal printing processing:

For metal foil printing, the metal foil is transferred to the surface of the substrate according to the selected hot or cold pressing method, and the necessary curing treatment is carried out to ensure a firm bond between the metal foil and the substrate.

For metal powder printing, a printing paste mixed with metal powder is applied to the surface of the substrate and the desired pattern is formed by the printing technique. Subsequent drying and curing are carried out to enhance the stability and durability of the printing effect.

Inspection and acceptance: Quality inspection of the finished metal printing products is carried out to ensure that the clarity, precision and adhesion of the patterns meet the design requirements.

3.CNC custom processing in the metal printing technology application cases

3.1 Fashion apparel industry

In the field of fashion apparel, metal printing technology combined with CNC custom processing has brought unique visual effects and high-end texture to clothing. For example, a high-end brand accurately cuts out complex pattern outlines through CNC technology and adopts the hot-pressing metal foil printing process to print fine metal patterns on garment fabrics. These patterns are not only colorful and glossy, but also closely integrated with the fabrics, showing an extraordinary sense of fashion and luxury. In addition, metal powder printing is also widely used in the custom processing of textiles, through the mixing of metal powder and printing paste, forming a unique texture on the fabric with a metallic texture, which enhances the overall grade and visual effect of the garment.

3.2 Automobile manufacturing industry

In the automobile manufacturing industry, metal printing technology also plays an important role. Automobile manufacturers use CNC custom processing technology, combined with metal foil printing or metal powder printing process, in the vehicle appearance parts (such as wheel hubs, air intake grills, door decorative strips, etc.) printed on the exquisite metal patterns or logos. These metal printing elements not only enhance the vehicle’s recognizability and aesthetics, but also enhance the vehicle’s sense of luxury and sportiness. For example, certain high-end models use CNC precision-cut metal foils as the logo decoration, which are firmly affixed to the surface of the vehicle body through the hot-pressing process, demonstrating the unique brand charm and craftsmanship level.

3.3 Electronic products

With the continuous development of electronic products, metal printing technology is also widely used in the custom processing of the shell of cell phones, tablet PCs, smart watches and other electronic products. Through CNC custom processing technology, various patterns, textures or brand logos can be accurately engraved on the metal shell, and combined with metal foil printing or metal powder printing process, bringing a more unique and personalized appearance for electronic products. This metal printing technology not only enhances the aesthetics and texture of the product, but also strengthens its durability and resistance to wear and tear. For example, a smartphone brand uses a combination of CNC processing and metal foil printing process to print a beautiful metal pattern on the back shell of the phone, bringing users a new visual experience and feel enjoyment.

3.4 Home decoration industry

In the field of home decoration, metal printing technology also brings more design possibilities and aesthetics to home furnishings. For example, through the CNC custom processing technology, can be printed on the metal picture frames, decorative plates, wall decorations and other household items on the exquisite metal patterns or textures, for the home environment to add a unique artistic atmosphere and high-end sense. In addition, metal printing technology can also be applied to the surface decoration of metal furniture, by printing a variety of patterns and textures to enhance the visual effect and tactile experience of the furniture.

Precautions

Material selection: Select the appropriate substrate and metal printing material according to the use and performance requirements of the product.

Process control: In the process of CNC machining and metal printing, all process parameters should be strictly controlled to ensure the stability of the processing quality and printing effect.

Safety protection: metal processing and printing process involves high temperature, high pressure and other dangerous factors, need to do a good job of safety protection measures to ensure the personal safety of operators.

Environmental protection: the waste materials and waste water generated during the processing need to be properly disposed of in accordance with environmental requirements to reduce the impact on the environment.

Customized metal printing type service FAQ

1. What are the advantages and disadvantages of metallic foil printing?

● Printing effect of high gloss and high adhesion, which can significantly enhance the grade and aesthetics of the product.

●Bright colors, can achieve a variety of metallic color effects.

●Applicable to a wide range of substrates, such as metal plates, textiles, etc.

How to choose the right type of metal printing?

2. The following factors need to be considered when choosing the right type of metal printing:

Product use: Choose the right type of metal printing according to the use and performance requirements of the product. For example, for products requiring high gloss and luxury, metal foil printing may be more suitable; while for products pursuing special texture and three-dimensional feeling, metal powder printing may be more advantageous.

Substrate characteristics: Consider the impact of the substrate’s material, surface flatness and other factors on the printing effect. Different substrates have different adaptability to metal printing, and need to be selected according to the actual situation.

Cost budget: the cost of metal foil printing and metal powder printing are different, and should be selected according to the cost budget.

Design requirements: according to the design requirements of the product and the customer’s personalized needs to choose the appropriate type of metal printing and pattern design.

3. How long is the cycle time of metal printing customization service?

The cycle time of metal printing customization service varies from project to project, and is affected by many factors, such as order size, printing type, substrate characteristics, design complexity, etc. Generally speaking, the cycle time from design confirmation to finished product delivery may range from several days to several weeks. Customers are recommended to clarify the specific requirements and expected delivery time with the service provider during the consultation, so that the service provider can provide a more accurate cycle time estimation.