Introduction

1. What is CNC?

1.1 Definition and Core Concept

- Automated Operation: Machines run unattended once programmed

- High Precision: Achieves tolerances as tight as ±0.001mm

- Repeatability: Consistent results across multiple parts

- Complex Geometry: Capable of producing intricate shapes

- Flexibility: Easy program changes for different parts

1.2 Evolution of CNC Technology

- 1950s: First CNC machines using vacuum tubes

- 1970s: Microprocessors revolutionize CNC systems

- 1990s: Windows-based interfaces and CAD/CAM integration

- 2000s: High-speed machining and 5-axis capabilities

- Today: Smart manufacturing and Industry 4.0 integration

2. CNC System Components

2.1 Hardware Components

- Bed and Frame: Provides structural rigidity

- Spindle: Rotates cutting tools at high speeds

- Worktable: Holds and positions the workpiece

- Guideways: Precision tracks for linear movement

- Feed Mechanisms: Translate motor motion to linear movement

- Servo Motors: Precise control of axis movements

- Stepper Motors: Cost-effective for simpler applications

- Ball Screws: Convert rotational motion to linear motion

- Linear Guides: Support and guide moving components

- Operator Interface: Display screen and input devices

- Emergency Stop: Safety shutdown mechanism

- Manual Controls: Handwheels and buttons for setup

2.2 Control System

- Central Processing Unit (CPU): Main computer brain

- Memory: Stores programs and parameters

- Input/Output Interfaces: Connect to external devices

- Control Circuits: Regulate machine functions

- Operating System: Manages system resources

- Control Software: Executes machining programs

- User Interface: Programming and monitoring tools

- Diagnostic Tools: Troubleshooting and maintenance

2.3 Measurement and Feedback Systems

- Encoders: Measure rotational position of motors

- Linear Scales: Directly measure linear movement

- Laser Interferometers: High-precision calibration tools

- Real-time position monitoring

- Automatic error correction

- Improved accuracy and stability

3. CNC Working Principle

3.1 The CNC Process Flow

- Create 2D or 3D digital model using Computer-Aided Design software

- Define dimensions, tolerances, and material specifications

- Ensure design is manufacturable (DFM principles)

- Convert CAD model to machine-readable code using Computer-Aided Manufacturing software

- Generate toolpaths, cutting parameters, and machining strategies

- Simulate and verify program to prevent errors

- Mount workpiece securely on machine table

- Install appropriate cutting tools

- Set up fixtures and clamps

- Calibrate tool lengths and offsets

- Load program into CNC controller

- Run program in single-block or automatic mode

- Monitor machining process

- Make adjustments as needed

- Measure finished part dimensions

- Check surface quality

- Verify tolerances are met

- Document results for quality control

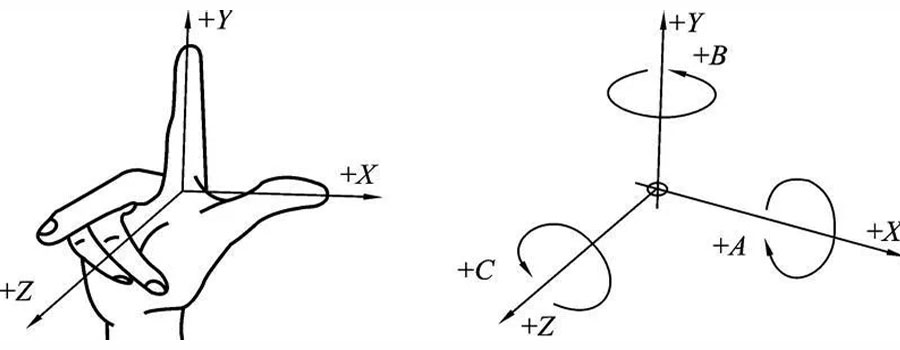

3.2 Coordinate System Fundamentals

- Fixed reference frame based on machine’s home position

- Absolute coordinates for all machine movements

- Consistent reference point for all operations

- User-defined coordinate system relative to workpiece

- Multiple coordinate systems (G54-G59) for different setups

- Simplifies programming for complex parts

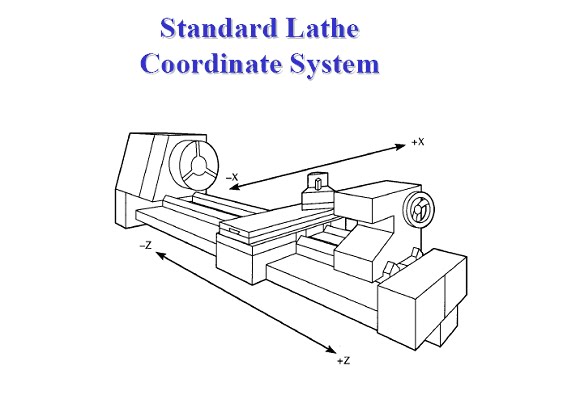

- X-Axis: Horizontal movement perpendicular to spindle

- Y-Axis: Horizontal movement perpendicular to X-axis

- Z-Axis: Vertical movement along spindle axis

- A, B, C Axes: Rotational axes for multi-axis machines

4. CNC Programming Languages

|

G-Code

|

Function

|

Description

|

|

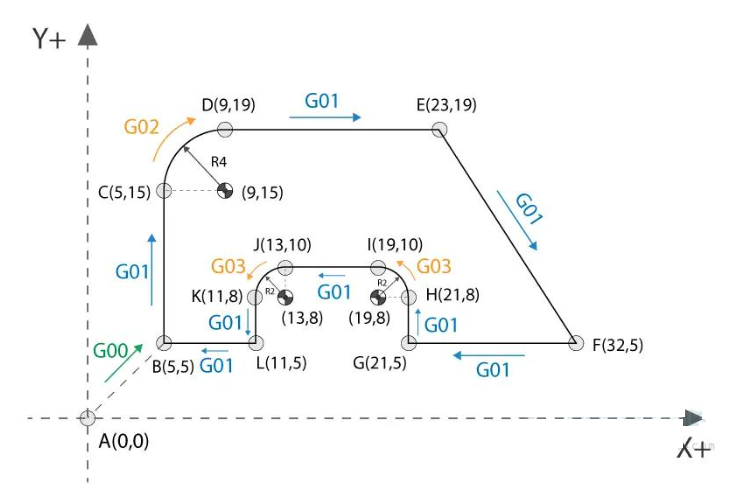

G00

|

Rapid Positioning

|

Fast movement to specified coordinates

|

|

G01

|

Linear Interpolation

|

Linear cutting movement at specified feed rate

|

|

G02

|

Circular Interpolation (Clockwise)

|

Circular cutting in clockwise direction

|

|

G03

|

Circular Interpolation (Counterclockwise)

|

Circular cutting in counterclockwise direction

|

|

G20

|

Inch Units

|

Set units to inches

|

|

G21

|

Metric Units

|

Set units to millimeters

|

|

G28

|

Return to Home Position

|

Move to machine reference position

|

|

G40

|

Tool Radius Compensation Cancel

|

Disable tool radius compensation

|

|

G41

|

Tool Radius Compensation Left

|

Enable left compensation

|

|

G42

|

Tool Radius Compensation Right

|

Enable right compensation

|

|

G54-G59

|

Work Offset Selection

|

Select workpiece coordinate system

|

|

G90

|

Absolute Positioning

|

Use absolute coordinates

|

|

G91

|

Incremental Positioning

|

Use incremental coordinates

|

|

G94

|

Feed Rate per Minute

|

Set feed rate in mm/min or in/min

|

|

G95

|

Feed Rate per Revolution

|

Set feed rate in mm/rev or in/rev

|

4.2 M-Code Functions

|

M-Code

|

Function

|

Description

|

|

M00

|

Program Stop

|

Pause program execution

|

|

M01

|

Optional Stop

|

Pause if optional stop button is active

|

|

M02

|

Program End

|

End of program, no return to start

|

|

M30

|

Program End and Reset

|

End program and return to start

|

|

M03

|

Spindle Forward

|

Start spindle clockwise rotation

|

|

M04

|

Spindle Reverse

|

Start spindle counterclockwise rotation

|

|

M05

|

Spindle Stop

|

Stop spindle rotation

|

|

M08

|

Coolant On

|

Start coolant flow

|

|

M09

|

Coolant Off

|

Stop coolant flow

|

|

M30

|

Program End and Reset

|

End program and reset to start

|

|

M6

|

Tool Change

|

Automatic tool change

|

4.3 Other Important Codes

- Format: Sxxxx (e.g., S3000 = 3000 RPM)

- Controls rotational speed of spindle

- Format: Fxxxx (e.g., F200 = 200 mm/min)

- Controls cutting speed of tool

- Format: Txx (e.g., T03 = Tool 3)

- Selects specific tool from tool magazine

5. CNC Machine Types

5.1 CNC Lathes

- Spindle: Rotates workpiece at high speeds

- Turret: Holds multiple cutting tools

- Chuck: Secures workpiece

- Tailstock: Supports long workpieces

- Shafts and rods

- Threaded components

- Cylindrical parts

- Contoured surfaces

5.2 CNC Milling Machines

- Spindle: Rotates cutting tools

- Worktable: Moves in X, Y, Z axes

- Tool Changer: Automatic tool exchange

- Coolant System: Controls cutting temperatures

- Flat surfaces

- Complex 3D shapes

- Slots and pockets

- Custom components

5.3 Multi-Axis Machines

- X, Y, Z Axes: Linear movements

- A, B Axes: Rotational movements

- Capabilities: Complex 3D shapes in single setup

- Applications: Aerospace, medical, mold making

5.4 Specialized CNC Machines

- High-precision surface finishing

- Tight tolerances (±0.0001mm)

- Applications: Tool and die making

- Non-contact cutting

- High precision and speed

- Applications: Sheet metal, plastics

- Machining hard materials

- Complex shapes and fine details

- Applications: Mold making, aerospace

6. Advantages of CNC Machining

6.1 Precision and Accuracy

- Tight Tolerances: Achieves ±0.001mm or better

- Consistency: Parts are identical batch to batch

- Repeatability: Same results every time

- Reduced Human Error: Automated operation minimizes mistakes

6.2 Efficiency and Productivity

- 24/7 Operation: Unattended machining

- Faster Setup: Quick program changes

- Reduced Scrap: Precise material usage

- Higher Cutting Speeds: Advanced toolpath strategies

6.3 Flexibility and Versatility

- Quick Changeover: Program changes instead of mechanical adjustments

- Multiple Part Types: Same machine for different components

- Complex Shapes: Capable of intricate geometries

- Prototype to Production: Seamless transition

6.4 Cost Savings

- Reduced Labor Costs: Less operator involvement

- Lower Scrap Rates: Precision machining

- Increased Throughput: Higher production rates

- Longer Tool Life: Optimized cutting parameters

7. Applications of CNC Technology

7.1 Aerospace Industry

- Engine Components: Turbine blades, casings

- Structural Parts: Wing components, landing gear

- Precision Requirements: ±0.001mm tolerances

- Materials: Titanium, aluminum, composites

7.2 Automotive Industry

- Engine Parts: Blocks, heads, crankshafts

- Transmission Components: Gears, shafts, housings

- Mass Production: High-volume manufacturing

- Quality Standards: IATF 16949 compliance

7.3 Medical Device Manufacturing

- Implants: Hip, knee, dental implants

- Surgical Instruments: Scalpels, forceps

- Biocompatible Materials: Titanium, stainless steel

- Regulatory Compliance: FDA, ISO 13485

7.4 Electronics Industry

- Components: Connectors, heat sinks

- Enclosures: Phone cases, computer parts

- Precision: Micro-machining capabilities

- Materials: Aluminum, plastics, brass

7.5 Tool and Die Making

- Molds: Injection, blow molding

- Dies: Stamping, forging

- High Precision: Tight tolerance requirements

- Customization: One-of-a-kind tools

8. CNC Programming Methods

8.1 Manual Programming

- Direct G-code programming at machine control panel

- Best for simple parts and small production runs

- Requires deep understanding of G-code and machine capabilities

- Limited to basic geometries

- Quick for simple parts

- No additional software needed

- Good for manual adjustments

- Time-consuming for complex parts

- Prone to programming errors

- Limited to experienced programmers

8.2 Computer-Aided Programming (CAM)

- Use CAM software to generate G-code from CAD models

- Automatic toolpath generation

- Simulation and verification capabilities

- Support for complex geometries

- Mastercam: Widely used in industry

- SolidWorks CAM: Integrated with SolidWorks

- UG NX CAM: High-end manufacturing solution

- Fusion 360: Cloud-based CAD/CAM

- BobCAD-CAM: Cost-effective solution

- Faster programming for complex parts

- Reduced errors through simulation

- Support for advanced machining strategies

- Integration with CAD systems

8.3 Conversational Programming

- Graphical interface for programming

- Menu-driven input of dimensions and parameters

- No G-code knowledge required

- Good for simple to moderate complexity parts

- Small job shops

- Prototyping

- Simple part production

- Operator-friendly environments

9. Quality Control in CNC Machining

9.1 Inspection Tools and Methods

- Coordinate Measuring Machine (CMM): 3D measurement of complex parts

- Optical Comparator: 2D profile measurement

- Micrometers and Calipers: Basic dimensional measurement

- Surface Roughness Tester: Ra, Rz measurements

- Tool Presetter: Tool length and diameter measurement

- Force Sensors: Detect tool wear and breakage

- Temperature Sensors: Monitor cutting temperatures

- Vibration Analysis: Detect machine instability

- Vision Systems: Real-time part inspection

9.2 Statistical Process Control (SPC)

- Monitor process variation

- Detect trends and anomalies

- Prevent defects before they occur

- Continuous improvement

- Cp/Cpk: Process capability indices

- Control Charts: X-bar, R-chart, S-chart

- Process Variation: Standard deviation, range

- Defect Rates: PPM (parts per million)

9.3 Tolerance Standards

- ISO Tolerance Grades: IT01 to IT18

- ANSI B4.1: American standard for limits and fits

- DIN 7168: German tolerance standard

- JIS B 0401: Japanese tolerance standard

- Rough Machining: ±0.1mm to ±0.05mm

- Finish Machining: ±0.05mm to ±0.01mm

- Precision Machining: ±0.01mm to ±0.001mm

- Ultra-Precision: ±0.001mm or better

10. Future Trends in CNC Technology

10.1 Industry 4.0 Integration

- Internet of Things (IoT): Connected machines and devices

- Big Data Analytics: Process optimization through data

- Artificial Intelligence: Predictive maintenance, quality control

- Digital Twin: Virtual simulation of machines and processes

- Increased productivity

- Predictive maintenance

- Real-time monitoring

- Remote diagnostics

10.2 Advanced Machining Technologies

- Spindle speeds up to 60,000 RPM

- Higher feed rates and material removal rates

- Improved surface finish

- Reduced cycle times

- Hybrid machines combining additive and subtractive processes

- 3D printing for complex geometries

- CNC machining for precision finishing

- Rapid prototyping and small production runs

10.3 Automation and Robotics

- Robotic Loading/Unloading: 24/7 operation

- Automated Guided Vehicles (AGVs): Material transport

- Flexible Manufacturing Systems (FMS): Integrated production lines

- Cobots: Collaborative robots working with humans

10.4 Sustainability in Manufacturing

- Energy Efficiency: Low-power machine designs

- Coolant Recycling: Reduced environmental impact

- Waste Reduction: Precision machining minimizes scrap

- Material Recycling: Metal recycling programs

Conclusion

- CNC systems use computer programs to control machine tools

- Precision, repeatability, and automation are defining characteristics

- Coordinate systems and programming languages enable complex machining

- Understanding of G-code and M-code programming

- Familiarity with different CNC machine types and their applications

- Knowledge of quality control methods and tolerance standards

- CNC technology is used across industries from aerospace to medical

- Programming methods range from manual to advanced CAM software

- Future trends include Industry 4.0, AI integration, and sustainability

Frequently Asked Questions (FAQ)

Q: What is the difference between CNC and conventional machining?

Q: How difficult is it to learn CNC programming?

Q: What are the most common CNC machine types?

Q: What software is used for CNC programming?

Q: What tolerances can CNC machines achieve?

Q: What materials can be machined with CNC?

Q: How much does a CNC machine cost?

Q: What skills are needed to work with CNC machines?

Q: What is the future of CNC technology?

Q: How important is CNC in modern manufacturing?

Disclaimer

- All information, opinions, and data contained in this article are for the purpose of information transmission only and do not constitute any advice on investment, transactions, law, medical care, or other matters.

- The content of the article is compiled based on public information or created based on the author’s personal understanding. Although every effort is made to ensure accuracy, it does not guarantee the completeness, accuracy, and timeliness of the information, nor does it bear any responsibility for any losses caused by the use of the content of this article.

- If the article involves third-party opinions, pictures, data, and other content, the copyright belongs to the original author. In case of infringement, please contact us for deletion.

- Readers should make independent decisions based on their actual situation and combined with professional opinions. The user shall bear all consequences arising from the use of the content of this article.