I. What is CNC Machining

Definition of CNC

CNC, short for Computer Numerical Control, refers to an automated machining technology that controls the movements of machine tools through computer programs. Simply put, in CNC machining, information such as processing requirements and machining routes is written into a program using specified codes. This program is then input into the numerical control device, which in turn controls the machine tool, enabling the tool and workpiece to move along a predetermined trajectory and parameters, thus machining parts that meet the design requirements.

Role of CNC

- High – precision machining: CNC machining can achieve extremely high machining accuracy. Its positioning accuracy and repeat positioning accuracy far exceed those of traditional machining methods, meeting the stringent accuracy requirements of industries such as aerospace and medical devices. For example, in the manufacturing of aerospace engine blades, CNC machining can ensure their precise production.

- Automated production: With the help of automated loading and unloading systems and tool management systems, CNC machining can achieve unmanned automated production, reducing manual intervention and improving production efficiency. It is particularly suitable for mass production, such as the large – scale manufacturing of automotive parts.

- Machining of complex – shaped parts: Thanks to its powerful programming capabilities, CNC machining can complete the machining of various complex curved surfaces and irregularly – structured parts, which is difficult to achieve with traditional machining methods. For instance, in the manufacture of precision molds, it can easily achieve the machining of complex mold cavities.

- High processing flexibility: By simply changing the processing program, it can quickly adapt to the processing requirements of different parts, realizing the conversion of various processing methods and meeting diverse and personalized production needs. It has obvious advantages in small – batch and multi – variety production scenarios.

Introduction to the CNC System

- Numerical control system: The core of CNC machining, it interprets the processing program and converts it into control signals to control the movements of the machine tool. Common ones include FANUC and Siemens.

- Machine tool body: The mechanical part for actual cutting, including components such as the machine bed, providing the mechanical structure and motion platform. Different types are suitable for different processing techniques.

- Servo drive device: Receives signals from the numerical control system and drives the motor to move the machine tool’s coordinate axes. Its performance affects the machine tool’s motion performance.

- Measurement and feedback device: Detects the motion parameters of the machine tool and feeds them back to the numerical control system to achieve closed – loop control and improve machining accuracy. Common ones include grating rulers and encoders.

II. Introduction to CNC – Machined Parts

CNC Part Processing Technology

- Common CNC machining technologies

- CNC turning: Mainly used for machining of rotary parts. Through the rotation of the workpiece and the linear or curvilinear movement of the tool, surfaces such as outer circles, inner holes, threads, and conical surfaces can be processed. For example, the crankshaft of an automobile engine can be precisely processed to form journal and connecting rod journal and other rotary structures through CNC turning.

- CNC milling: Using a rotating milling cutter to cut the workpiece, it can machine various complex shapes such as planes, step surfaces, grooves, and curved surfaces. It is widely used in fields such as mold manufacturing and mechanical part processing. For example, the cavity of an injection mold is usually processed by CNC milling, which can accurately shape the complex mold shape.

- CNC drilling: With the help of a drill bit, holes of various sizes and precisions are processed on the workpiece. It is often used for hole processing of components in mechanical assembly. For example, numerous bolt holes on an automobile engine block can be accurately positioned and processed through CNC drilling.

- Electrical discharge machining (EDM): Based on the principle of electrical discharge erosion, a pulsed voltage is applied between the workpiece and the electrode to generate discharge sparks, eroding the workpiece material to achieve the processing purpose. It is suitable for processing high – hardness, complex – shaped conductive materials. For example, when processing carbide molds, EDM can achieve the forming of complex shapes.

- CNC grinding: Using a high – speed rotating grinding wheel to grind the workpiece surface to obtain a high – precision and low – surface – roughness processing effect. It is often used for the processing of parts with extremely high requirements for surface quality and dimensional accuracy, such as the precision grinding of aerospace engine blades.

Advantages of CNC Parts

- High precision: With an advanced numerical control system and precise mechanical structure, CNC machining can achieve extremely high dimensional and shape accuracy, with tolerances controlled within ±0.01mm or even smaller, meeting the demanding precision requirements of industries.

- High consistency: The processing process is completely controlled by the program, eliminating the interference of human factors and ensuring that the size, shape, and quality of each part are highly consistent, guaranteeing the stability of product quality.

- Strong ability to process complex shapes: It can achieve multi – axis linkage through programming and can machine complex curved surfaces and irregular structures that are difficult to complete by traditional processing methods. For example, the impeller of an aerospace engine, with its complex curved surface structure, can only be accurately manufactured by relying on CNC machining.

- High production efficiency: The automated processing process reduces manual operation time and can achieve continuous production. At the same time, a fast tool – changing system and efficient cutting parameters greatly shorten the processing cycle of a single part, improving overall production efficiency.

- High processing flexibility: By simply modifying the processing program, it can quickly switch to processing different types of parts, adapting to the small – batch and multi – variety production mode and meeting diverse market demands.

CNC Processing Materials

- Aluminum alloy: It has a low density, is lightweight, has high strength, good corrosion resistance, excellent thermal conductivity, and good processing performance, and can be processed into complex shapes. It is widely used in the aerospace (aircraft fuselage, wings, etc.) and automotive industries (engine blocks, wheels, etc.).

- Stainless steel: It has excellent corrosion resistance, strength, and oxidation resistance and can be used for a long time in harsh environments. Due to its high hardness, it is difficult to machine and is often used in medical devices, food, and chemical equipment.

- Titanium alloy: It has high strength, low density, high – temperature resistance, and corrosion resistance and is used in key components of aerospace and the medical field. However, its machining requires high cutting force, generates high temperatures, causes severe tool wear, has a complex process, and is costly.

- Copper and copper alloys: They have excellent electrical and thermal conductivity, good plasticity, and relatively good processing performance. However, due to their low hardness, they are prone to deformation during processing, affecting the surface quality. They are commonly used in electronic and electrical appliances and machinery manufacturing.

- Plastics: There are many types, such as ABS, PC, nylon, etc. They are lightweight, low – cost, have good electrical insulation, and are easy to process and form. ABS is used for electronic product casings, toys, etc.; PC is used for optical lenses, lamp covers, etc.; nylon is used for mechanical parts, bearings, etc.

III. Customized CNC – Machined Part Services

Why Customize CNC Parts

- Meet unique design requirements: When enterprises are engaged in research and development and innovation, they often need parts with unique structures and functions that cannot be met by standard parts. Customized CNC parts can be precisely manufactured according to design drawings, facilitating product innovation, such as in the research and development of medical equipment.

- Adapt to specific application scenarios: Different industries and scenarios have different requirements for the performance, size, and material of parts. Customized CNC parts can be designed and manufactured as required to ensure stable and efficient operation in specific environments, such as parts for oil extraction equipment.

- Optimize product performance and quality: Customized CNC parts can select suitable materials and processes and optimize the structural design to improve product performance and quality, such as automotive engine parts.

- Achieve small – batch production: For small – batch products or parts, traditional mold – making has high costs and long cycles. Customized CNC parts do not require mold – making, have low costs and short cycles, are suitable for small – batch production, and help enterprises reduce costs and quickly respond to the market.

Process of Customizing CNC Parts

- Demand communication and design confirmation: The customer communicates the part requirements, provides design drawings or models. When there is no complete design, our engineers assist in the design, and both parties confirm the plan.

- Process planning and programming: Process engineers plan the processing technology according to the design plan and use CAM software to convert it into a processing program.

- Raw material procurement and preparation: Purchase raw materials according to material requirements, inspect them, and carry out pretreatment.

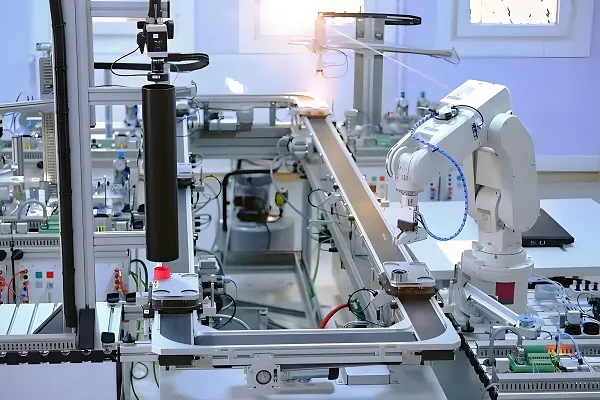

- CNC machining: Input the program into the machine tool, start processing after debugging, and the operator monitors and adjusts in real – time.

- Quality inspection: After processing, comprehensively inspect the part quality using professional equipment.

- Post – processing and packaging for delivery: Perform post – processing on the parts according to customer requirements, package the qualified parts, and deliver them.

Precautions for Customizing CNC Parts

- Clarify design requirements: Before customization, the customer should ensure the accuracy and completeness of the design drawings or models, clearly mark key information such as dimensional tolerances, surface roughness, material requirements, and heat – treatment requirements to avoid processing errors or quality problems due to unclear design.

- Reasonably select materials: Select appropriate materials according to the usage scenarios and performance requirements of the parts. Consider factors such as material processing performance, cost, and supply situation. On the premise of meeting performance requirements, try to choose materials that are easy to process and have a lower cost. At the same time, ensure the reliability of the material supplier to guarantee the stability of material quality.

- Communicate closely with the processing manufacturer: During the customization process, the customer should maintain close communication with the processing manufacturer, keep informed of the processing progress and problems. Seriously consider and actively negotiate to solve the process improvement suggestions or questions raised by the processing manufacturer to jointly ensure the smooth processing of the parts.

- Pay attention to processing accuracy and quality: Processing accuracy and quality are the keys to customizing CNC parts. The customer should understand the quality control system and inspection capabilities of the processing manufacturer and require the processing manufacturer to provide quality inspection reports. When inspecting the parts, strictly inspect them according to the design requirements and quality standards. If there are quality problems, communicate with the processing manufacturer in a timely manner to solve them.

- Pay attention to intellectual property protection: If the customized parts involve intellectual property issues, the customer should sign relevant confidentiality agreements and intellectual property agreements with the processing manufacturer to clarify the rights and obligations of both parties in terms of intellectual property and protect their own intellectual property from infringement.

IV. Surface Treatment Processes for CNC – Machined Parts

Surface treatment processes are crucial for CNC – machined parts. They not only improve the appearance quality of parts but also significantly enhance their performance and extend their service life. The following are some common surface treatment processes:

- Electroplating: Using the principle of electrolysis, a metal or alloy is deposited on the surface of a metal part. For example, galvanizing has a low cost and provides corrosion protection, and nickel – plating is used for protective decoration and functional repair.

- Anodizing: For aluminum and aluminum – alloy parts, an aluminum oxide film is formed on their surface, which has various properties such as protection and decoration.

- Surface polishing: By grinding and other methods, surface defects of the part are removed to make it smooth. It is divided into manual and mechanical polishing and is used in the processing of jewelry, electronic product casings, etc.

- Sandblasting treatment: High – speed media is used to impact the part surface to remove oil stains, etc., and increase the surface roughness, improving the adhesion of coatings or the friction performance.

- Heat treatment: Heating and cooling metal parts to change their internal organizational structure and improve their mechanical properties. Common methods include annealing, etc.

- Electroless plating: A metal coating is formed on the part surface through a chemical reaction, such as electroless nickel – plating and silver – plating, which can evenly cover complex workpieces.

- Coating treatment: Coating a paint on the part surface to form a film to enhance corrosion resistance, etc. Common methods include spraying, etc., and there are various types of coatings.

V. CNC – Machined Precision Parts

What are CNC Precision Parts

CNC precision parts are parts manufactured through computer numerical control machining technology, featuring high – precision dimensional tolerances, high surface quality, and complex geometric shapes. They play a crucial role in fields with extremely high requirements for accuracy and performance, such as aerospace and medical devices. For example, the turbine blades of aerospace engines, with their complex curved surfaces and strict dimensional accuracy, need to be manufactured by CNC precision processing technology to ensure the stable and efficient operation of the engine in extreme environments. In the medical device field, the manufacturing of implants such as artificial joints also relies on this technology to ensure accurate dimensions and smooth surfaces, meeting the physiological needs of the human body and long – term use safety.

Factors Affecting the Precision of CNC Parts

- Equipment accuracy: The accuracy of the mechanical structure and transmission system of the CNC machine tool, such as the pitch accuracy of the lead screw and the straightness of the guide rail. Insufficient machine tool accuracy or wear and aging can lead to a decline in processing accuracy.

- Tool selection and wear: Different tools are suitable for different processing scenarios. Tool wear will affect the dimensional accuracy and surface roughness of the part. When processing hard materials, insufficient tool wear resistance can easily lead to rapid wear and cause errors.

- Cutting parameter setting: Unreasonable settings of cutting speed, feed rate, and cutting depth can cause problems such as workpiece deformation and decreased surface quality.

- Workpiece material characteristics: The characteristics of the material, such as hardness, toughness, and thermal expansion coefficient, vary. Hard materials are difficult to machine, and materials with a large thermal expansion coefficient are prone to deformation due to heat, affecting accuracy, such as titanium alloy.

- Processing environment: The temperature, humidity, and vibration in the workshop affect the processing accuracy. Temperature changes cause thermal expansion and contraction, and vibration causes relative displacement between the tool and the workpiece.

- Fixture design and workpiece clamping: If the fixture design is unreasonable or the clamping is not firm, the workpiece is likely to displace or deform. For complex or thin – walled workpieces, a suitable fixture and clamping method are crucial.

- CNC programming and operation: Human factors such as incorrect writing of the processing program, inaccurate coordinate calculation, unskilled operation, and improper parameter adjustment can lead to processing accuracy problems. For example, an unreasonable tool path planning affects the processing accuracy.

How to Improve the Precision of CNC Parts

- Equipment upgrade and maintenance: Select high – precision and high – stability CNC machine tools and regularly maintain the machine tools, including checking and calibrating key components such as the lead screw, guide rail, and spindle, and timely replacing worn parts to ensure that the machine tool is always in the best working condition.

- Optimize tool management: According to the workpiece material and processing requirements, select appropriate tool materials, tool geometries, and tool coatings to improve the cutting performance and durability of the tool. Establish a tool wear monitoring mechanism, regularly check the tool wear situation, and timely replace or re – grind the tool. At the same time, use the tool compensation function to compensate for the dimensional deviation caused by tool wear.

- Accurate process planning: Before processing, conduct a comprehensive process analysis of the part and develop a reasonable processing process route. Reasonably arrange the processing sequence to reduce the number of workpiece clamping times and processing deformation. According to the characteristics of the workpiece material and tool, accurately set the cutting parameters, and find the optimal combination of cutting parameters through trial – cutting and optimization.

- Control the processing environment: Control the temperature and humidity in the processing workshop within an appropriate range to reduce the impact of temperature and humidity changes on the machine tool and workpiece. Vibration – isolation treatment should be carried out in the workshop to avoid external vibration interfering with the processing process and create a stable environment for high – precision processing.

- Optimize fixture design and clamping: Design special fixtures according to the shape, size, and processing requirements of the workpiece to ensure that the fixture has sufficient rigidity and stability, can firmly hold the workpiece, and ensure the positioning accuracy of the workpiece during the processing. Adopt a reasonable clamping method to avoid workpiece deformation during clamping.

- Improve programming and operation levels: Strengthen the training of programming personnel to improve programming skills and ensure the accuracy and efficiency of the processing program. Operators should be proficient in the operation method of the machine tool, strictly follow the operating procedures, and be able to adjust parameters in a timely and accurate manner during the processing to deal with various unexpected situations.

- Introduce advanced detection technologies: During the processing, use on – line detection technologies, such as coordinate measuring machines and laser measuring instruments, to monitor the processing dimensions and shapes of parts in real – time, and promptly discover and correct processing errors. Analyze the detection data and feedback it to the processing process to continuously optimize the processing process and improve processing accuracy.

VI. CNC – Machined Part Manufacturers

Xiamen Jinben Industrial Co., Ltd. is a national high – tech enterprise with 26 years of machining experience. The company focuses on the research and manufacturing of high – precision parts, covering various types of parts such as injection – molded, machined, and stamped parts. It provides a one – stop service from mold design and manufacturing to part mass production and assembly, with a professional team of industrial designers and engineers.

The production equipment is advanced, with the accuracy of 5 – axis processing equipment reaching ±0.005mm. Strict quality control is carried out in all aspects. In mold manufacturing, various types can be provided, and in the fields of injection – molding, 3D printing, and stamping, there are also advantageous products.

The company adheres to the principles of “high quality, high efficiency, and sincere service” and the tenet of “sustainable operation, customer first”. It has established stable cooperation with more than 100 partners, obtained international standard certifications such as SGS, RoHS, and CE, and has won recognition and trust in the market.

The production equipment is advanced, with the accuracy of 5 – axis processing equipment reaching ±0.005mm. Strict quality control is carried out in all aspects. In mold manufacturing, various types can be provided, and in the fields of injection – molding, 3D printing, and stamping, there are also advantageous products.

The company adheres to the principles of “high quality, high efficiency, and sincere service” and the tenet of “sustainable operation, customer first”. It has established stable cooperation with more than 100 partners, obtained international standard certifications such as SGS, RoHS, and CE, and has won recognition and trust in the market.

If you are looking for high – quality and high – precision CNC part customization services, don’t hesitate! Just leave your valuable information in the comment area below, including detailed part specifications, material requirements, estimated order quantity, expected delivery time, etc. Our professional team will contact you as soon as possible. We promise to provide you with the most professional technical advice, the most reasonable price plan, and the best service experience to help your project progress smoothly. Hurry up and leave a message to start the customization journey. Looking forward to creating brilliance with you!