Waterjet cutting systems are powerful tools used in industries ranging from metalworking to aerospace, relying on high-pressure water (often mixed with abrasive materials) to cut through tough materials with precision. The performance of these systems depends on their core components, known as waterjet parts. Each part works in harmony to generate, control, and direct the high-pressure stream, ensuring clean, accurate cuts and reliable operation. From pumps that generate pressure to nozzles that focus the stream, every component is critical to the system’s functionality.

1. Types of Waterjet Parts

High-Pressure Generation Components

- Waterjet Pump: The pump is the heart of the waterjet system, responsible for pressurizing water to extreme levels (typically 30,000 to 90,000 PSI). There are two main types: intensifier pumps and direct-drive pumps. Intensifier pumps use hydraulic pressure to boost water pressure, ideal for heavy-duty industrial use, while direct-drive pumps use a motor to drive a crankshaft, offering higher flow rates for faster cutting.

- Pressure Intensifier: Found in intensifier pumps, the pressure intensifier converts low-pressure hydraulic oil into high-pressure water. It consists of a piston that pushes water through a small orifice, amplifying pressure. Regular maintenance of seals and pistons in the intensifier is crucial to prevent pressure loss.

- Accumulator: The accumulator stores high-pressure water to maintain consistent pressure during cutting, reducing fluctuations that can affect cut quality. It acts as a buffer, ensuring a steady stream even when the pump cycles on and off.

Cutting and Nozzle Components

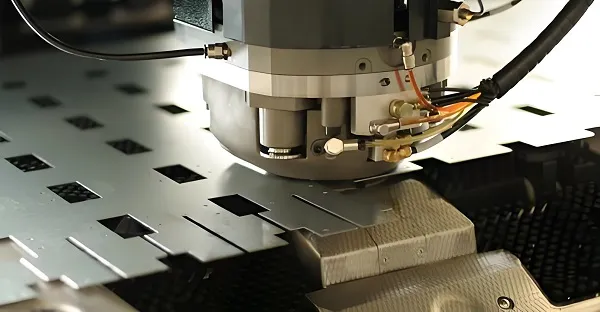

- Nozzle Assembly: The nozzle assembly is where the high-pressure water (or water-abrasive mixture) is focused into a narrow stream. It includes a jewel orifice (made from ruby, sapphire, or diamond) that controls the water flow and a mixing tube that combines water with abrasive (in abrasive waterjets). The orifice size determines the stream diameter, while the mixing tube length affects cutting precision.

- Abrasive Delivery System: In abrasive waterjets, this system feeds abrasive materials (such as garnet) into the water stream. It includes a hopper, metering valve, and delivery line. The metering valve controls the abrasive flow rate, which impacts cutting speed and material removal.

- Focusing Tube: Also known as the mixing tube, the focusing tube guides the abrasive-water mixture to the workpiece. Made from tough materials like carbide or stainless steel, it withstands the abrasive wear caused by the high-speed stream.

Control and Movement Components

- Motion Control System: This system includes linear guides, motors, and drive rails that move the nozzle or workpiece along X, Y, and Z axes. CNC (Computer Numerical Control) systems precisely control these movements, enabling complex cuts with tight tolerances. Servo motors ensure smooth, accurate positioning for intricate designs.

- Pressure Regulator: The pressure regulator adjusts the water pressure based on the material being cut. Lower pressure is used for soft materials like foam or plastic, while higher pressure is needed for metals and stone. Some systems feature automatic pressure adjustment for optimal performance.

- Valves: High-pressure valves control the flow of water and abrasive. Solenoid valves actuate quickly to start or stop the cutting stream, while relief valves protect the system from overpressure by releasing excess water.

Safety Components

- Pressure Relief Valve: This critical safety part prevents system damage by releasing pressure if it exceeds safe limits, protecting pumps, hoses, and other components from rupture.

- Guard and Enclosure: A protective guard surrounds the cutting area to contain water, abrasive, and debris, shielding operators from flying particles and high-pressure spray. Many enclosures include viewing windows for monitoring the cutting process.

2. Processable Materials for Waterjet Parts

Metals

- Stainless Steel: Used in accumulators, valves, and structural components, stainless steel offers corrosion resistance and strength, essential for withstanding high-pressure water and harsh industrial environments.

- Carbide: Tungsten carbide is ideal for mixing tubes and focusing tubes due to its extreme hardness and wear resistance. It withstands the abrasive wear from garnet and high-speed water flow, extending component life.

- Alloy Steel: Alloy steel (e.g., 4140) is used in pump crankshafts, pistons, and pressure vessels. It provides high tensile strength and fatigue resistance, critical for components under constant pressure and stress.

Ceramics and Jewels

- Ruby/Sapphire: These hard, wear-resistant materials are used for orifices in nozzle assemblies. Ruby orifices are cost-effective for low-pressure systems, while sapphire orifices offer longer life in high-pressure applications.

- Diamond: Diamond orifices are the most durable, suitable for ultra-high-pressure systems (over 60,000 PSI). They maintain their shape longer, reducing the need for frequent replacement in heavy-duty cutting.

Polymers and Composites

- High-Pressure Hoses: Made from reinforced rubber or polyurethane with steel braiding, these hoses carry high-pressure water from the pump to the nozzle. The braided layers provide strength to withstand extreme pressure, while the inner rubber layer resists water and chemical degradation.

- Seals and Gaskets: Made from materials like PTFE (Teflon) or Viton, seals prevent leaks in pumps, valves, and intensifiers. They must withstand high pressure, temperature fluctuations, and exposure to water and abrasive.

3. Step-by-Step Manufacturing Process of Waterjet Parts

Design and Engineering

Engineers use CAD software to design waterjet parts, focusing on precision and durability. Simulations test how components handle high pressure, abrasive wear, and thermal stress. For example, finite element analysis (FEA) ensures pump housings can withstand pressure without deformation, while computational fluid dynamics (CFD) optimizes nozzle designs for efficient water flow.

Material Sourcing and Preparation

Materials are selected based on component function. High-pressure parts like pumps and valves use certified alloy steel or stainless steel, sourced from reputable suppliers. Orifices are cut from synthetic ruby, sapphire, or diamond blanks, while mixing tubes are machined from carbide rods. Raw materials undergo testing for purity and strength before processing.

Fabrication and Machining

- Metal Processing: Steel components are forged, machined, or cast to shape. Pump cylinders are precision-honed to ensure smooth piston movement, while valves are CNC-machined to tight tolerances for leak-free operation. Heat treatment (e.g., quenching and tempering) strengthens alloy steel parts, enhancing their pressure resistance.

- Ceramic/Jewel Machining: Ruby or sapphire orifices are laser-drilled to create precise holes (typically 0.003 to 0.020 inches in diameter). Diamond orifices are polished to a mirror finish to minimize water turbulence and extend life.

- Composite Hoses: High-pressure hoses are constructed by layering rubber or polyurethane with steel braiding. The inner tube is extruded, then wrapped with braided steel for reinforcement, and covered with an outer protective layer.

Assembly and Testing

- Component Assembly: Parts are assembled into subassemblies (e.g., pump units, nozzle assemblies). Seals and gaskets are installed to prevent leaks, and moving parts are lubricated for smooth operation. The motion control system is calibrated to ensure precise axis movement.

- Pressure Testing: Assembled systems undergo rigorous pressure testing. Pumps are run at maximum pressure to check for leaks, while valves and hoses are tested for burst resistance. Nozzles are evaluated for stream consistency and cutting accuracy using test materials.

Quality Inspection and Certification

Each part is inspected for dimensional accuracy using CMMs (Coordinate Measuring Machines) and optical gauges. Orifices are checked for hole roundness and surface finish, while metal parts are inspected for cracks or defects using ultrasonic testing. Parts that meet standards are certified for use in waterjet systems, with documentation of material specs and test results.

4. Customizing Waterjet Parts

Sharing Requirements

To customize waterjet parts, customers provide details such as system pressure, material to be cut, and desired cut quality. For example, a customer cutting thick steel may need a larger orifice and high-flow mixing tube, while one cutting glass may require a low-abrasive nozzle. Drawings or 3D models of custom parts (e.g., specialized nozzles or mounting brackets) help manufacturers understand specifications.

Engineer Consultation

Manufacturing engineers review requirements to recommend materials and designs. They may suggest carbide mixing tubes for abrasive applications or diamond orifices for long production runs. For custom motion control systems, engineers optimize rail lengths and motor power to match the customer’s workpiece size and cutting speed needs.

Prototype Development

Prototypes of custom parts (e.g., unique nozzles or valve assemblies) are produced using rapid prototyping or CNC machining. These prototypes are tested in actual cutting conditions to evaluate performance, such as stream stability or pressure resistance. Adjustments are made to the design based on test results, ensuring the final part meets expectations.

Production and Delivery

After prototype approval, mass production begins. Custom parts are manufactured using the same precision processes as standard parts, with strict quality control. Finished parts are packaged to prevent damage during shipping and delivered with installation guides. Many manufacturers offer technical support to help customers integrate custom parts into their waterjet systems.

5. Application Fields of Waterjet Parts

Metalworking

Waterjet parts are essential in metal fabrication, cutting steel, aluminum, and titanium with minimal heat-affected zones. High-pressure pumps and abrasive nozzles handle thick metal plates, while precision motion control systems enable intricate cuts for automotive or aerospace components.

Stone and Glass Cutting

In stone fabrication, waterjets cut marble, granite, and quartz into countertops and tiles. Soft abrasive delivery systems and fine orifices prevent chipping, while CNC controls ensure precise edge detailing. For glass cutting, low-pressure waterjets with diamond orifices create clean, crack-free cuts.

Aerospace and Defense

Aerospace manufacturers use waterjets to cut complex shapes in composites, alloys, and ceramics. Custom nozzles and high-pressure pumps achieve tight tolerances (±0.001 inches) required for aircraft parts, while abrasive-resistant mixing tubes handle the tough materials used in defense applications.

Automotive and Manufacturing

Waterjets cut gaskets, trim, and body panels in automotive production. Flexible motion control systems adapt to varying workpiece sizes, while efficient abrasive delivery reduces material waste. Waterjet parts also enable rapid prototyping, allowing manufacturers to test new designs quickly.

6. Manufacturing Challenges of Waterjet Parts

Handling High Pressure and Wear

Waterjet parts must withstand extreme pressure (up to 90,000 PSI) and abrasive wear from garnet. Orifices and mixing tubes degrade over time, requiring precise material selection and manufacturing to extend life. Balancing durability with cost is a challenge—diamond orifices last longer but are expensive, while ruby orifices are cheaper but need frequent replacement.

Ensuring Leak-Free Performance

Even tiny leaks in pumps, valves, or hoses can reduce pressure and compromise cut quality. Achieving leak-free seals in high-pressure components requires tight machining tolerances and high-quality seals. Manufacturers must ensure surfaces are smooth and flat to prevent seal damage under pressure.

Maintaining Precision in Motion Control

The motion control system must move the nozzle or workpiece with micron-level accuracy for complex cuts. Any backlash or vibration in rails, motors, or drives can cause errors. Engineers address this by using high-precision linear guides, servo motors, and CNC calibration to minimize movement errors.

7. Expert Manufacturing Tips for Waterjet Parts

Optimizing Orifice and Mixing Tube Design

Matching orifice size to mixing tube length improves cutting efficiency. A larger orifice increases water flow for faster cutting, while a longer mixing tube enhances abrasive acceleration. Manufacturers use CFD simulations to optimize these dimensions for specific materials and pressures.

Selecting Materials for Wear Resistance

For abrasive applications, choosing carbide mixing tubes with a hardness of 90+ HRC (Rockwell Hardness) extends life. Coatings like titanium nitride (TiN) can further reduce wear on metal components. For high-pressure seals, Viton offers better chemical resistance than rubber, ideal for industrial environments.

Calibrating Pressure and Flow

Proper calibration of pumps and regulators ensures consistent pressure. Regularly checking accumulator pressure and adjusting relief valves prevents pressure spikes. Manufacturers also recommend using filtered water to reduce orifice clogging and extend component life.

8. Common Questions About Waterjet Parts

Q: How often should waterjet nozzles be replaced?

A: Nozzle life depends on use—ruby orifices last 50–100 hours in abrasive systems, while sapphire lasts 100–200 hours, and diamond 500+ hours. Mixing tubes typically last 10–50 hours, depending on abrasive flow rate. Replace nozzles when cut quality degrades (e.g., rough edges or slower cutting).

Q: Can waterjet parts be repaired, or must they be replaced?

A: Some parts (e.g., pump seals, valves) can be repaired by replacing worn components like O-rings or pistons. However, orifices, mixing tubes, and severely worn hoses must be replaced, as damage compromises performance and safety.

Q: What causes pressure loss in waterjet systems?

A: Pressure loss often results from worn seals, clogged orifices, or damaged hoses. Leaks in the pump or intensifier reduce pressure, while a dirty orifice restricts flow. Regular maintenance (e.g., seal replacement, filter cleaning) helps prevent pressure loss.

9. Get Your Waterjet Parts Today

Need reliable waterjet parts to keep your cutting system running at peak performance? We offer a full range of high-quality components, from pumps and nozzles to motion control systems and safety parts. Our custom solutions are tailored to your specific application, whether you’re cutting metal, stone, or composites. With strict quality control and expert engineering support, we ensure your waterjet parts deliver precision and durability. Contact us today to order replacement parts or discuss custom designs!