1. What Are CNC Anodized Aluminum Parts?

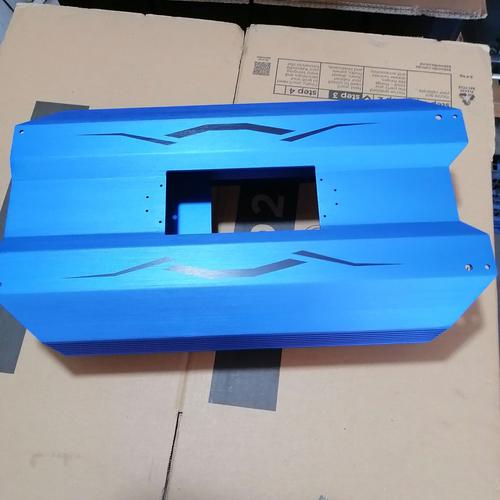

They’re aluminum components first shaped by CNC machining (milling, turning) for tight precision (±0.005mm typical), then treated with anodization—an electrochemical process that grows a hard, protective oxide layer on the surface. Think: a CNC-machined smartphone frame (sleek, precise) + anodizing (scratch-resistant, colored)—a combo that’s super useful for parts needing both form and durability.

Unlike plain CNC aluminum, the anodized layer (5–25μm thick) stops rust, resists wear, and lets you add colors (black, silver, gold) without paint chipping.

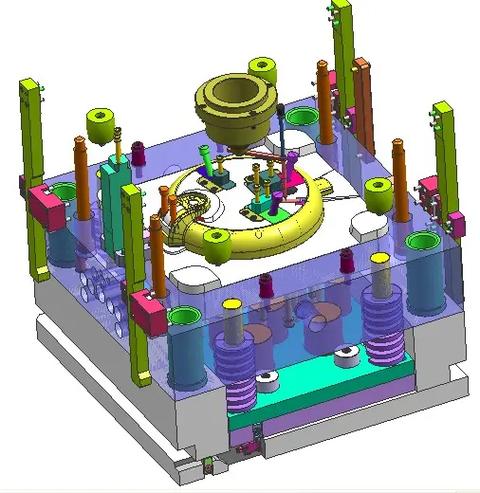

2. How Are They Made? (4 Simple Steps)

The process pairs CNC’s accuracy with anodizing’s protection—no extra fuss:

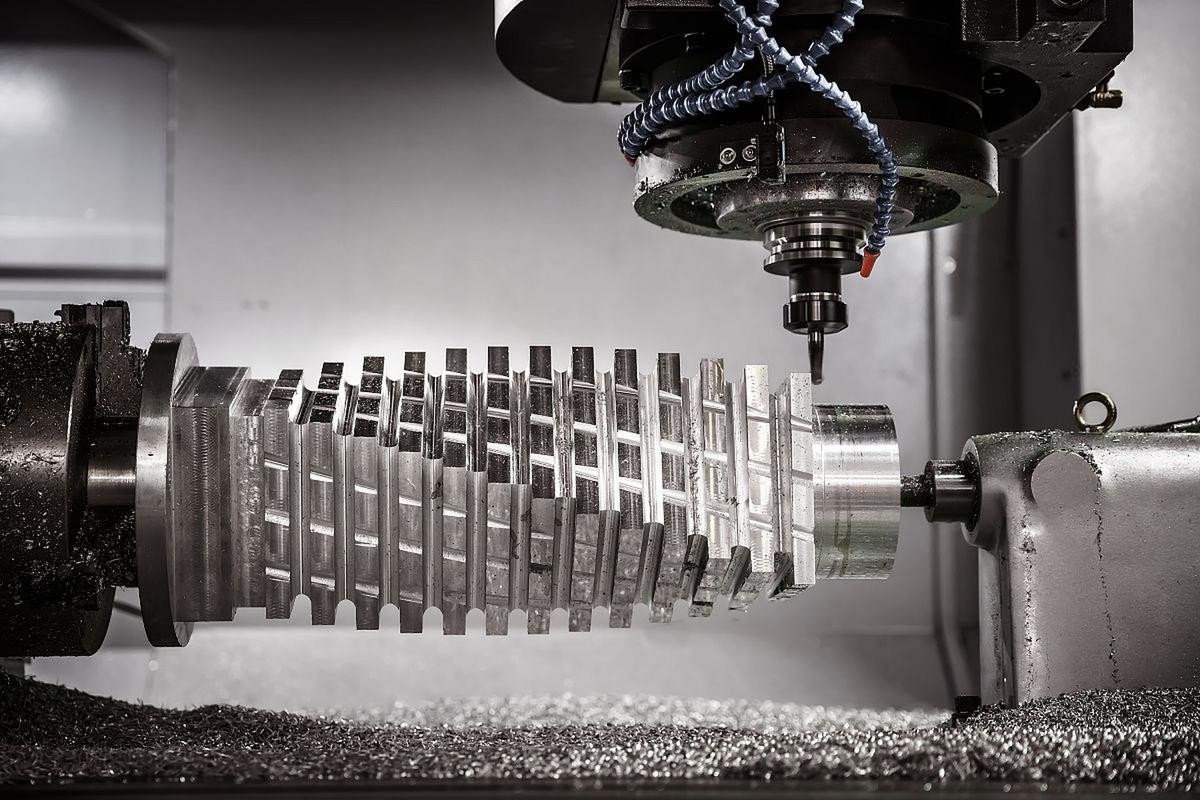

- CNC Machining First: Shape the aluminum (6061, 7075 most common) into the final part (e.g., EV bracket, drone arm). This step locks in precision—critical for parts that need to fit perfectly.

- Prep Carefully: Clean the part to remove oil, chips, or fingerprints (dirty surfaces ruin anodization!). Lightly etch the surface to help the oxide layer stick.

- Anodization: Submerge the part in an electrolyte bath (usually sulfuric acid) and pass an electric current. The aluminum surface reacts to form a porous oxide layer—this is what makes it tough.

- Seal the Layer: Close the oxide pores with hot water or a sealant. This step boosts corrosion resistance—key for outdoor or wet-use parts.

3. Why They’re So Popular

Two big wins from combining CNC and anodizing:

- Precision + Protection: CNC gets the part’s shape right; anodizing keeps it looking new. A CNC-anodized laptop hinge, for example, stays smooth and scratch-free for years.

- Versatility: Anodization works with any CNC-machined aluminum part—from tiny sensor housings (φ5mm) to large EV battery trays (1m+). Colors add style too—great for consumer gadgets.

4. Common Uses

You see them daily, even if you don’t notice:

- Electronics: Smartphone frames, laptop bases (anodized black = sleek + scratch-proof).

- Automotive: EV charging port covers, interior trim (resists heat and spills).

- Aerospace: Small brackets (lightweight, corrosion-resistant for high altitudes).

5. A Quick Pro Tip

For parts that need extra durability (like outdoor gear), go for a thicker anodized layer (15–25μm) instead of the thin 5μm option. It adds a little cost but makes the part way more long-lasting.

Final Thought

CNC anodized aluminum parts are all about balance: CNC’s precision makes them work, anodizing makes them last. Whether it’s a gadget you hold or a car part you rely on, this combo is super reliable—and that’s why it’s everywhere.