CNC brass hardware fittings refer to precision-manufactured components made from brass alloys using Computer Numerical Control (CNC) machining technology. Unlike manually crafted hardware, CNC brass fittings are produced via automated tools (e.g., CNC lathes, mills, drills) programmed with digital designs, ensuring consistent dimensional accuracy (typically ±0.01mm to ±0.1mm), repeatability for high-volume production, and uniform quality across every piece.

Brass—an alloy of copper (60–70%) and zinc (30–40%)—is uniquely suited for CNC hardware due to its excellent machinability, natural corrosion resistance, and aesthetic appeal. Common examples include screws, nuts, plumbing valves, electrical terminals, furniture handles, and decorative fasteners.

1. Types of CNC Brass Hardware Fittings (With Applications)

CNC brass hardware spans diverse categories, each optimized for specific industry needs. Below is a detailed breakdown of the most common types, their design features, and CNC machining advantages:

1.1 CNC Brass Fasteners (Screws, Nuts, Bolts)

- Design Features: Precision-threaded (metric, UNC, or custom pitches), available in head styles like hexagonal, pan, or round; often with chamfered edges for easy installation.

- CNC Machining Edge: Automated threading ensures uniform thread depth and pitch, minimizing cross-threading risks. Tight diameter tolerances (±0.02mm) enable compatibility with precision equipment (e.g., electronics).

- Typical Applications: Electronics (PCB mounting screws), furniture assembly (wooden cabinet bolts), medical devices (non-magnetic fasteners for MRI-compatible tools).

- Reading Key Points Tips: Prioritize CNC brass fasteners for applications requiring corrosion resistance and non-magnetism; opt for custom threading for unique equipment needs.

1.2 CNC Brass Plumbing Fittings (Valves, Connectors, Adapters)

- Design Features: Smooth internal bores (to prevent fluid flow restriction), leak-proof sealing surfaces (e.g., O-ring grooves), and compatibility with standard pipe sizes (1/2″, 3/4″, etc.).

- CNC Machining Edge: Multi-axis CNC mills create complex internal channels (e.g., 3-way valve ports) with minimal material waste. Surface finishes (Ra 0.8–1.6μm) reduce friction and prevent mineral buildup in water systems.

- Typical Applications: Residential plumbing (faucet connectors), industrial fluid systems (chemical-resistant adapters), beverage equipment (food-grade valves for brewing machines).

- Reading Key Points Tips: Choose CNC brass plumbing fittings for wet environments—brass’s patina layer prevents rust, unlike steel or iron alternatives.

1.3 CNC Brass Electrical Components (Terminals, Connectors, Bushings)

- Design Features: Conductive, non-magnetic, and often plated (nickel, tin, or gold) to enhance electrical conductivity and prevent tarnishing; thin-walled bushings (0.5mm+ thickness) for insulation.

- CNC Machining Edge: CNC turning produces concentric cylindrical parts (e.g., terminal pins) with consistent wall thickness, critical for reliable electrical contact.

- Typical Applications: Automotive wiring (battery terminals), electronics (USB-C connectors), power tools (insulating bushings for wiring).

- Reading Key Points Tips: For electrical use, select tin-plated CNC brass components—tin improves conductivity and resists oxidation better than bare brass.

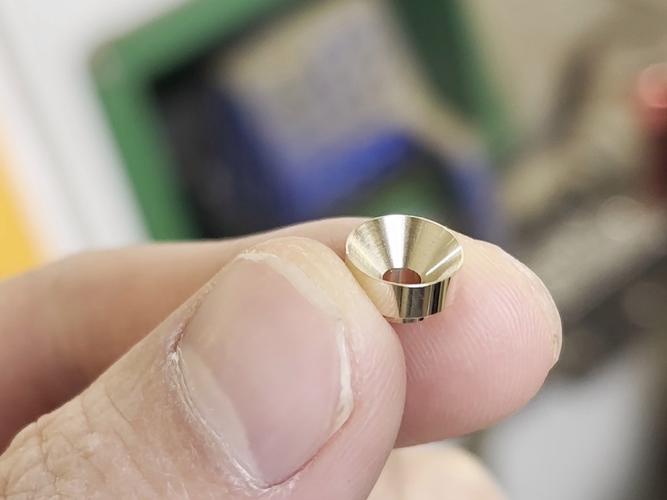

1.4 CNC Brass Decorative Hardware (Handles, Knobs, Embellishments)

- Design Features: Intricate details (e.g., engraved patterns, curved profiles) and finishes like polished, brushed, or antiqued (to match interior aesthetics).

- CNC Machining Edge: 5-axis CNC machines carve complex 3D designs (e.g., floral motifs on furniture knobs) that are impossible to replicate with manual tools. Consistent finishing ensures uniform color and texture across batches.

- Typical Applications: Luxury furniture (cabinet handles), jewelry boxes (decorative fasteners), architectural hardware (door knobs for heritage buildings).

- Reading Key Points Tips: Use 5-axis CNC brass decorative hardware for custom projects—engraving can be tailored to brand logos or design themes.

2. Why Choose Brass for CNC Hardware Fittings? Key Benefits

Brass offers unique advantages over other metals (e.g., steel, aluminum) for CNC hardware, making it a top choice across industries:

2.1 Excellent Machinability

Brass requires lower cutting forces and produces minimal tool wear, enabling high-speed CNC machining. For example:

- CNC lathes can operate at 3,000–5,000 RPM when turning brass (vs. 2,000–3,000 RPM for steel), reducing production time by 20–30%.

- Brass chips (waste material) are brittle and easy to remove, preventing tool clogging and reducing downtime.

2.2 Natural Corrosion Resistance

Brass forms a thin, protective oxide layer (patina) when exposed to air and moisture. This layer prevents rust and degradation, making CNC brass hardware suitable for:

- Outdoor applications (e.g., garden furniture screws) – withstands rain and humidity for 5–10 years without significant damage.

- Wet environments (e.g., plumbing valves) – no rust buildup to block water flow or contaminate fluids.

2.3 Aesthetic Versatility

Brass’s warm, golden tone can be enhanced with diverse surface treatments:

- Polishing: Creates a mirror-like finish (Ra 0.2–0.4μm) for luxury goods (e.g., high-end furniture knobs).

- Plating: Nickel or chrome plating adds a modern silver tone; gold plating elevates decorative pieces (e.g., jewelry box hinges).

- Antiquing: Chemical treatments create a vintage patina for heritage restoration projects.

2.4 Non-Magnetic & Conductive Properties

-

Non-magnetic: Critical for medical devices (e.g., MRI room hardware) and electronics (avoids interference with magnetic sensors).

-

Electrical conductivity: Brass has 28% of copper’s conductivity, making it ideal for low-voltage electrical components (e.g., terminal blocks, connectors).

-

Reading Key Points Tips: Brass’s combination of non-magnetism and conductivity makes it irreplaceable for medical and electrical CNC hardware—no other common alloy offers both traits at an affordable cost.

3. CNC Machining Process for Brass Hardware Fittings (Step-by-Step)

The production of CNC brass hardware follows a standardized workflow to ensure precision and quality. Below is a detailed breakdown:

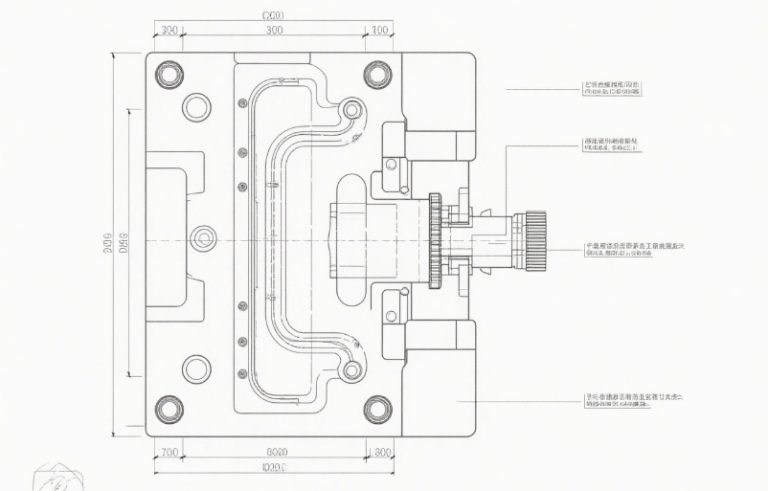

Step 1: Design & CAD Modeling

- Engineers create 3D CAD models (using SolidWorks, AutoCAD, or Fusion 360) defining dimensions, tolerances, and features (e.g., threads, holes).

- For custom parts, designs are optimized for CNC machining (e.g., adding 1–3° draft angles to avoid sharp edges that damage cutting tools).

Step 2: Brass Alloy Selection

- Choose the alloy based on application requirements:

- C36000 (Free-Cutting Brass): 61.5% copper, 35.5% zinc, 3% lead – best for fasteners and fittings (excellent machinability).

- C26000 (Cartridge Brass): 70% copper, 30% zinc – higher ductility for bent parts (e.g., curved furniture handles).

- C38500 (Lead-Free Brass): <0.25% lead – compliant with RoHS and FDA standards (for food-contact or children’s products).

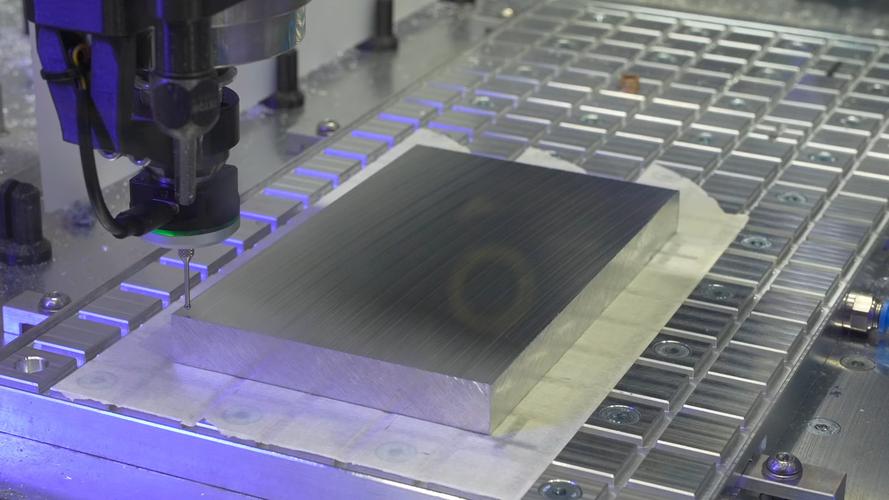

Step 3: CNC Machining

- CNC Turning: Used for cylindrical parts (e.g., screws, bushings) – a rotating brass bar is shaped by stationary cutting tools. Typical parameters: Speed = 3,500 RPM; Feed rate = 0.1–0.2 mm/rev.

- CNC Milling: Used for non-cylindrical parts (e.g., valve bodies, handles) – multi-axis mills cut complex shapes from brass blocks. Typical parameters: Speed = 2,500 RPM; Depth of cut = 0.5–1 mm.

- Drilling & Threading: Automated drills create holes (±0.01mm tolerance); thread mills or taps produce precise threads (e.g., M3, 1/4″-20 UNC).

Step 4: Surface Treatment

- Deburring: Remove sharp edges via CNC deburring tools or tumbling (with ceramic media) to prevent injury and improve fit.

- Finishing: Apply plating, polishing, or brushing as required – e.g., nickel plating for electrical terminals, polishing for decorative knobs.

Step 5: Quality Inspection

-

Dimensional Check: Use calipers, micrometers, or Coordinate Measuring Machines (CMM) to verify tolerances.

-

Material Testing: X-ray fluorescence (XRF) confirms alloy composition; salt spray tests validate corrosion resistance (24–48 hours for plumbing parts).

-

Reading Key Points Tips: For critical applications (e.g., medical, aerospace), insist on CMM inspection and material certificates—this ensures compliance with industry standards.

4. How to Select the Right CNC Brass Hardware Fittings?

Follow this checklist to choose fittings that align with your performance, cost, and design needs:

4.1 Define Application Requirements

- Environment: Outdoor/wet use → select lead-free brass (C38500) with nickel plating; electrical use → opt for tin-plated brass to enhance conductivity.

- Load Capacity: Structural parts (e.g., furniture bolts) → C36000 brass (tensile strength = 415 MPa); decorative parts → C26000 (more ductile for intricate shapes).

4.2 Check Tolerance & Precision

- High-precision applications (e.g., electronics) → require ±0.01mm tolerance; general use (e.g., furniture screws) → ±0.1mm is sufficient.

- Ask suppliers for a “Certificate of Conformance (CoC)” to confirm tolerance compliance.

4.3 Evaluate Surface Finish

- Functional parts (e.g., valves) → smooth finish (Ra 0.8μm) to reduce friction; decorative parts → polished or engraved finishes for aesthetics.

4.4 Consider Cost & Production Volume

-

Low volume (10–100 pieces): Custom CNC machining is cost-effective (no mold fees).

-

High volume (10,000+ pieces): Choose suppliers with automated CNC lines to lower per-unit costs (e.g., $0.50–$2 per brass screw).

-

Reading Key Points Tips: Balance cost and quality—avoid low-cost brass with high lead content (non-compliant with safety standards) for consumer or medical products.

5. Common Myths About CNC Brass Hardware Fittings (Debunked)

5.1 Myth 1: “Brass is too soft for durable hardware.”

- Fact: Brass has sufficient strength for most hardware applications. C36000 brass has a tensile strength of 415 MPa (comparable to low-carbon steel) and can withstand repeated use (e.g., furniture screws lasting 10+ years). For high-load parts, brass can be reinforced with manganese additives to boost strength to 500+ MPa.

5.2 Myth 2: “CNC brass hardware is more expensive than steel.”

- Fact: While brass material costs more than steel ($3–$5/kg vs. $1–$2/kg), CNC brass machining is faster (reducing labor costs). For high-volume production, the total cost difference is minimal (e.g., $0.10–$0.30 per part). Brass also requires less maintenance (no rust removal) than steel, lowering long-term costs.

5.3 Myth 3: “Brass hardware tarnishes easily and looks unprofessional.”

- Fact: Tarnish (patina) is a protective layer that can be controlled. Plating (nickel, chrome) prevents tarnishing entirely; unplated brass can be cleaned with a brass polish (e.g., Wright’s Brass Polish) to maintain shine. Many designers intentionally use patina as a desired aesthetic (e.g., vintage-style door knobs).

5.4 Myth 4: “All CNC brass hardware is the same—supplier choice doesn’t matter.”

-

Fact: Supplier expertise directly impacts quality. Low-quality suppliers may use impure brass (with iron or lead contaminants) that causes machining defects (e.g., cracked threads or uneven finishes). Choose suppliers with ISO 9001 certification and experience in your industry (e.g., FDA registration for food-contact parts).

-

Reading Key Points Tips: Always verify supplier credentials—cheap CNC brass hardware often cuts corners on material purity or machining precision, leading to premature failure.

6. Frequently Asked Questions (FAQs)

Q1: Can CNC brass hardware be used in food-contact applications (e.g., kitchen faucets)?

A1: Yes—select lead-free brass alloys (e.g., C38500, lead content <0.25%) compliant with FDA standards (21 CFR 175.300) and EU Regulation (EC) No 1935/2004. These alloys are non-toxic and safe for direct food contact.

Q2: What’s the maximum size of CNC brass hardware that can be manufactured?

A2: Most CNC machines handle parts up to 1,000mm in length (e.g., long brass rods for plumbing pipes) and 300mm in diameter (e.g., large valve bodies). For larger parts, suppliers may use multi-step machining or assembly (e.g., joining two brass sections for extra-long handles).

Q3: How long does CNC brass hardware last outdoors?

A3: Unplated brass lasts 5–10 years outdoors (developing a protective patina but no structural damage). Plated brass (nickel or chrome) lasts 15–20 years, as the plating blocks moisture and air exposure. For coastal areas (saltwater), use marine-grade brass (C46400) with extra corrosion resistance.

Q4: Can I get custom designs for CNC brass hardware?

A4: Yes—CNC machining excels at custom designs. Provide a 3D CAD file or sketch, and suppliers can produce one-off prototypes or high-volume custom parts (e.g., engraved company logos on knobs, custom thread sizes for unique equipment). Most suppliers offer design optimization to ensure machinability.

Q5: Is CNC brass hardware compatible with other metals (e.g., aluminum, steel)?

A5: Yes—brass is non-galvanic with most metals, so it won’t cause corrosion when paired with aluminum or steel. For example, brass screws can safely fasten aluminum furniture frames without galvanic corrosion (unlike steel screws, which react with aluminum). For long-term use, apply a thin layer of anti-seize compound to threaded connections.

CNC Brass Hardware—Precision, Durability, and Versatility

CNC brass hardware fittings combine brass’s natural advantages (corrosion resistance, machinability) with the precision of CNC technology, making them ideal for electronics, plumbing, furniture, and luxury goods. By understanding the types, manufacturing process, and selection criteria, you can choose fittings that meet your performance, safety, and aesthetic needs.

If you have specific requirements (e.g., “custom CNC brass electrical terminals” or “food-grade plumbing valves”), share your details in the comments—we’ll help you connect with trusted suppliers and optimize your design for CNC machining!