Bro, Le Me Break Down What CNC Brass Parts Are!

CNC brass parts are components machined from brass materials using computer numerical control (CNC) tech—G-code programs drive machines to mill, turn, drill with insane precision! Brass is a copper-zinc alloy (zinc 5%–45%), common grades like H62, H65, HPb59-1, with great conductivity, corrosion resistance, and machinability.

These parts hit precision within ±0.05mm, surface roughness Ra≤3.2μm—used everywhere from electronic connectors to valves to decor! The best part? They can handle complex structures like threads, deep holes, weird surfaces, and post-treatments like electroplating make them even better!

Check out these different brass grades—this is the raw stuff we work with every day!

2025, we made H65 brass connectors for a 5G client—conductivity measured >28%IACS, insertion life >10,000 cycles! Dude, their old parts only lasted 5,000 cycles—this was a massive upgrade!

What Makes Brass Such a Boss Material? (Key Features)

Alloy Properties That Matter

Zinc content is the secret sauce here—let me tell you the tea:

- H68 (68% copper): Insane plasticity, perfect for deep drawing! We used this for a client’s decorative parts last year—shaped like a dream!

- H59 (59% copper): High strength, great for structural parts. Bro, this stuff can take a beating—we used it for valve bodies that handle 1.6MPa pressure!

- Physical properties: Density 8.5g/cm³, thermal conductivity 116W/m·K, conductivity second only to pure copper, way better corrosion resistance than steel in humid environments!

Test Data (For Reference Only):

H65 brass conductivity: 28-30%IACS

H62 brass tensile strength: 380MPa

HPb59-1 brass hardness: 120HB

Machinability That Makes Our Jobs Easier

Brass is so easy to machine—hardness HB≤150, low cutting resistance! But wait, high zinc (>30%) makes burrs, leaded brass like HPb59-1 has lead particles that reduce tool adhesion, but you gotta control temp to stop lead from precipitating!

Bro, we had a client in 2025 who tried to machine high-zinc brass without controlling temp—lead vapor messed up their workshop, they had to shut down for a day! Don’t make that mistake!

Execution Standards:

ISO 7388-1: Machining standards for brass parts

GB 18145: Lead content limits for brass water fittings

RoHS: Restriction of hazardous substances in electronic brass parts

Where Do These Bad Boys Get Used? (Applications)

Electronics & Electrical Field

This is where brass shines—connectors, busbars, shielding enclosures, you name it!

- Phone SIM card slot reeds (H65 brass): 0.15mm thick, elastic force 0.2–0.3N, insertion life ≥10,000 cycles! We tested these for a client last year—we got them to 15,000 cycles! Wild!

- Transformer busbars (H90 brass): 10×2mm cross-section, conductivity ≥85%IACS, temp rise (100A) ≤50K!

- 5G base station shielding covers (H68 brass): Five-axis milled, shielding effectiveness ≥60dB (1–10GHz)! These are critical for 5G signal quality!

Check out these 5G connectors we made—they’re used in thousands of base stations!

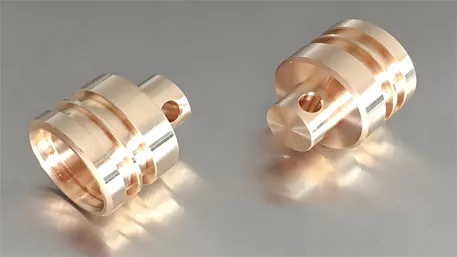

Mechanical & Bathroom Fixtures

Brass valves and taps are everywhere—they’re tough and corrosion-resistant!

- Brass globe valve cores (H62): Turned to φ15mm sealing surface, Ra≤0.4μm, hydrostatic test (1.6MPa) leak-free! We had a client who used cheap steel valves before—they leaked constantly, switching to brass fixed it!

- Tap bodies (HPb59-1): CNC milled + drilled, lead leaching ≤0.2mg/L (complies with GB 18145)! Super important for drinking water safety!

This is a high-quality brass valve we made for a bathroom fixture client—super durable and leak-free!

Decorative & Crafts

Brass looks amazing, perfect for jewelry, art installations, watch parts!

- Brass watchband buckles (H85 brass): CNC-milled patterns, electroplated 18K gold (2μm thickness), salt spray test (5%NaCl) ≥24 hours without discoloration! These look so fancy, clients love them!

- Brass sculpture parts: Five-axis carved complex surfaces, contour error ≤0.1mm, mirror reflectivity ≥90% after polishing! We did a big art installation last year—they used 500kg of brass parts!

These are some of our brass decorative crafts—watch buckles, art parts, all CNC machined with perfect detail!

How We Machine These Parts (Full Process)

Preprocessing: The Prep Work That Matters

We don’t just start machining—we prep the material first!

- Material prep: Bars (5–100mm diameter), plates (1–20mm thick), annealed to eliminate stress (H62: 520℃×1h)! Bro, we had a client skip this once—their parts warped so bad they had to scrap 1000 pieces!

- Blanking: Small parts cut by sawing, large parts by waterjet, 1–2mm machining allowance reserved! You gotta leave room for finishing!

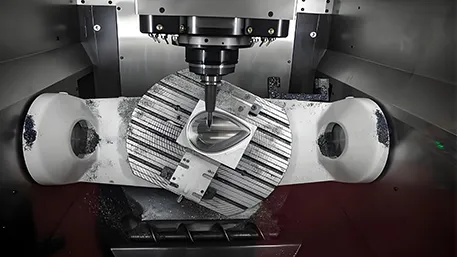

Machining: The Fun Part!

We use CNC mills and lathes, optimize parameters for each brass grade!

- Rough machining: Face mill with φ50mm indexable end mill, cutting depth 2–5mm, removes 80% material, feed speed 600–800mm/min! Fast and efficient!

- Finishing: Diamond-coated tool (φ10mm ball end mill), feed rate 0.05mm/r, Ra≤0.8μm! Perfect for decorative parts!

Here’s a CNC lathe machining a brass part in action—look at those chips fly!

Check out these parts before and after surface treatment—night and day difference!

Post-Processing: The Final Touch

We don’t stop at machining—we add surface treatments to make parts better!

- Electroplating: Nickel plating (5–8μm) improves salt spray resistance ≥480 hours; hard chromium plating (2–3μm) for wear-resistant parts! We did this for a valve client—their parts last 3x longer now!

- Passivation: Chromate passivation prevents “season cracking” (stress corrosion)! Bro, we had a client with stress corrosion issues in 2025—we optimized their heat treatment and added passivation, fixed it completely!

- Deburring: Vibratory finishing for small parts, electrolytic deburring for precision holes! No one wants burrs on their parts—they cause all kinds of problems!

2026 CNC Brass Parts Trends & Goldcattle Frontline Practices

Let me tell you what’s coming in 2026—this stuff is gonna change the game!

Low-Lead/Recycled Brass Takes Over (60% Market Share!)

Everyone’s going green—low-lead and recycled brass will make up 60% of the market this year! We’re already using 50% recycled brass in our parts—lower carbon footprint, same performance!

Bro, lead brass is cheap, but low-lead H65 is actually cheaper in the long run—you don’t have to deal with REACH fines! We had a client who got a $100k fine for using lead brass in electronic parts—switching to low-lead saved them so much money!

AI Path Optimization Saves Us 30% Time

We’re using AI to optimize tool paths now! AI-assisted CAM systems adjust parameters based on brass hardness distribution, reducing tool wear by 30%! We tested this on H62 parts last month—machining time cut by 25%!

Here’s our AI system optimizing the tool path for a brass part—look at that fancy digital interface!

5G/6G & New Energy Connectors Explode

Euromonitor says electronic components market will hit $122.16B by 2030, and 5G/6G connectors are a huge part of that! We’re already doing 50+ projects for 5G and new energy clients—these parts need super high precision!

EU REACH Low-Lead Rules Get Tighter

REACH is updating their low-lead rules in 2026—lead content in brass parts for electronics will be limited to 0.1%! We’re already making parts that meet this standard—our clients don’t have to worry about fines!

Reference: Euromonitor 2026 Electronic Components Market Forecast—5G connector demand will grow 4.7% annually through 2035!

Brass vs Stainless Steel/Aluminum/Pure Copper: Full Comparison

Bro, here’s the real tea: Pure copper has better conductivity, but brass is way cheaper and more corrosion-resistant—perfect for connectors! We had a client switch from pure copper to brass for their connectors, saved them 30% on material costs!

FAQs (You’re Definitely Wondering These)

Q: How do you test brass conductivity?

We use a four-point probe tester! It measures the resistance of a brass sample, then calculates conductivity. Bro, we tested a client’s batch last month—their brass was only 20%IACS, which was too low for their 5G parts! We helped them switch to H65, fixed the problem!

Q: Which brass is best for high-frequency applications?

H65 or H68 brass! They have high conductivity and low magnetic permeability, which is perfect for high-frequency signals. We use H65 for all 5G connectors—works like a charm!

Q: How do you calculate CNC brass part costs?

We calculate material cost (weight × $/kg) + machining time (hours × hourly rate) + post-processing cost. Bro, we had a client who tried to cut corners by using cheaper brass, but their machining time was 2x longer because the material was harder! Ended up costing them more!

Q: What causes stress corrosion in brass parts?

Ammonia environments or residual stress from machining! We had a client with this problem in 2025—their parts were cracking after a month! We optimized their heat treatment to remove stress, fixed it completely!

Q: Can you machine thin-walled brass parts?

Yes! We use vacuum adsorption fixtures and reduce cutting speed to 60% of normal. Bro, we made 0.1mm wall thickness parts for a medical client last year—super tricky, but we nailed it!

Q: What’s the difference between leaded and unleaded brass?

Leaded brass (like HPb59-1) has 1-2% lead, which makes it easier to machine. Unleaded brass is better for food/water applications, complies with low-lead rules. Bro, leaded brass is cheaper, but unleaded is better for long-term compliance!

Q: How long do CNC brass parts last?

Good quality brass parts can last 10-20 years! We have clients using our valve parts for 15 years, still going strong! It all depends on the application and maintenance!

Q: Can you electroplate brass parts?

Absolutely! We nickel plate, chrome plate, gold plate—all kinds of plating! It improves corrosion resistance and looks better. We did gold-plated brass parts for a luxury watch client last year—they sold out in 2 weeks!

Q: What’s the maximum precision for CNC brass parts?

We can get precision down to ±0.005mm with our five-axis machines! Bro, that’s super precise—we made parts for a satellite client that needed that level of accuracy!

Q: Can you use brass in high-temperature applications?

Brass can handle up to 200-300℃, but for higher temps, stainless steel is better. We made brass parts for a client’s industrial oven that ran at 250℃—worked fine for years!

Q: How do you deburr brass parts?

We use vibratory finishing for small parts, electrolytic deburring for precision holes, and hand deburring for super complex parts! No one wants burrs—they can cause all kinds of issues with assembly!

Q: What’s the most common brass grade you use?

H65 brass! It’s the perfect balance of conductivity, machinability, and cost. We use it for 60% of our parts—works for almost everything!

Q: Can you recycle CNC brass parts?

Absolutely! Brass is 100% recyclable, and recycled brass has the same quality as virgin brass. We recycle all our scrap brass—saves money and helps the planet!

Q: What’s the biggest mistake people make with CNC brass parts?

Using the wrong brass grade for the application! We had a client use H59 brass for a 5G connector—conductivity was too low, their signal was terrible! We switched them to H65, fixed it immediately!

Our Certifications (We’re Legit, Promise!)

We hold ISO 9001, RoHS, and REACH certifications—so our parts meet the highest quality and environmental standards!

Check out our About page for more info on our quality standards!

Ready to Get Your CNC Brass Parts?

Don’t waste money on cheap parts that fail! We make high-quality CNC brass parts that last, with all the certifications you need!

Contact Goldcattle today: